Ultrathin tube shell

An ultra-thin, tube-and-shell technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of reduced service life and uneven force, and achieve the effects of prolonging service life, reducing weight and eliminating shear force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

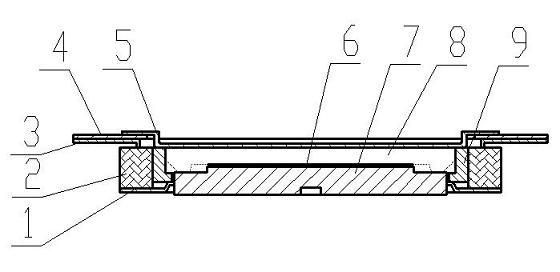

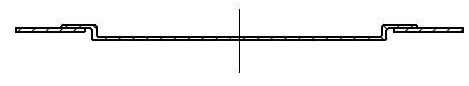

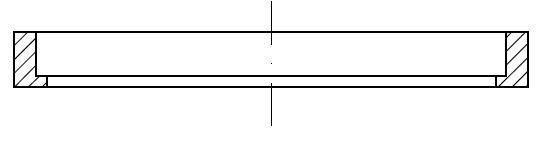

[0018] According to attached figure 1 It can be seen that the present invention specifically relates to an ultra-thin tube shell, including an upper cover, a positioning member, and a base, and is characterized in that it also includes a circular thick silver sheet 6, and the upper cover includes an outer ring sheet 4 and a disc-shaped The oxygen-free copper disc 5, the outer ring sheet 4 is connected to the edge of the oxygen-free copper disc 5; the base includes an annular metal sheet 1, a cylindrical shell 2, an annular edge 3 and a bottom block 7, The bottom block 7 is a circular structure with a protrusion in the middle, the edge 3 is fixed on the top of the shell 2, the upper surface of one end of the annular metal sheet 1 is welded to the shell 2, and the other end is nested and fixed on the shell 2. The lower part of the side wall of the bottom block 7, the thick silver sheet 6 is placed on the protrusion of the bottom block 7, the positioning member is a circular posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com