Steel-ultra-high performance concrete combined bridge deck structure with shearing resisting structure and construction method thereof

A technology of ultra-high performance and combined bridge deck, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problem that it is difficult to meet the application requirements of thin ultra-high performance concrete layers, difficult to realize thin ultra-high performance concrete layers, and shear key structures Large size and other issues, to achieve the effect of good operability and economy, strong flexibility and adaptability, and high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

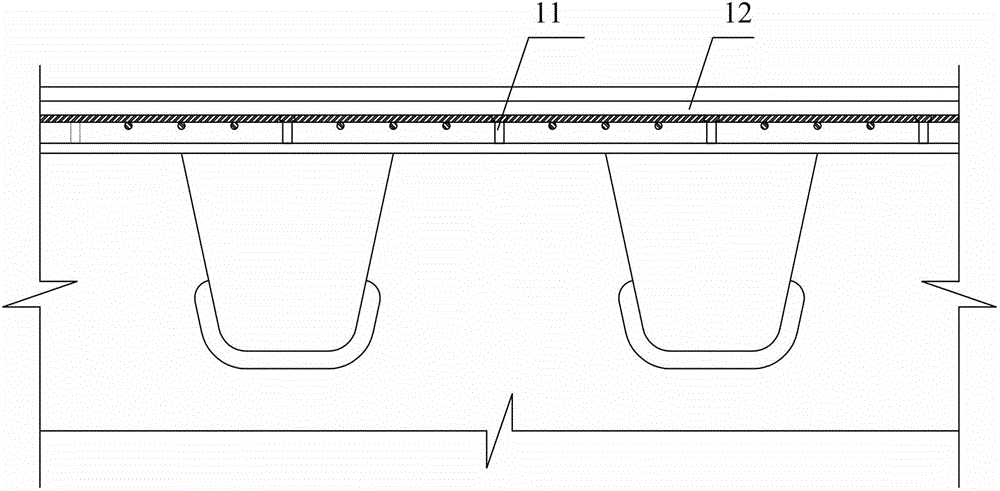

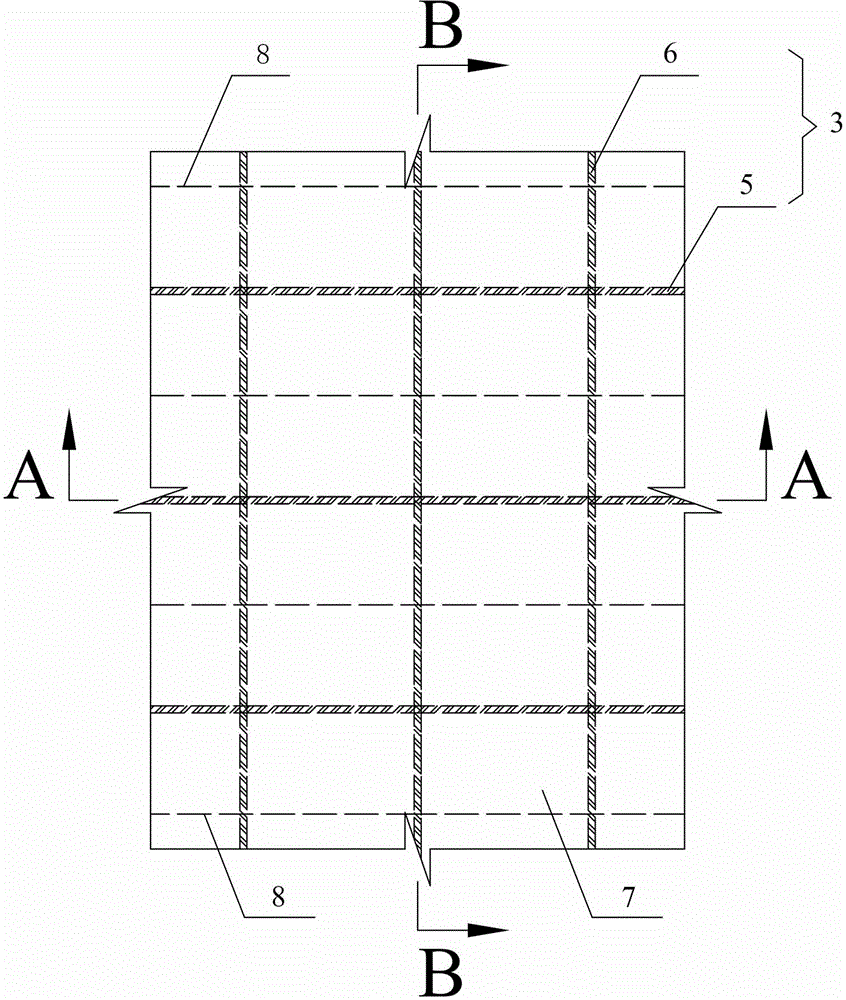

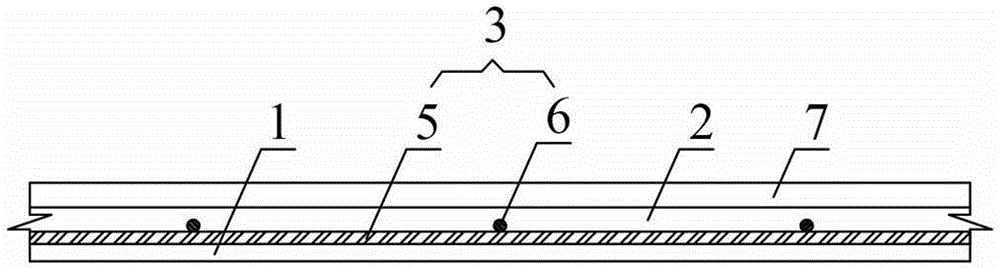

Embodiment 1

[0044] A sort of Figure 2 ~ Figure 4 The steel-ultra-high-performance concrete composite deck structure containing the shear structure of the present invention is shown, and the composite deck structure includes the steel bridge deck layer 1 below and the ultra-high-performance concrete layer poured on the steel bridge deck layer 1 2. The lower part of the steel bridge deck layer 1 is provided with longitudinal rib webs 8 , and the steel mesh shear structure 3 is welded above the steel bridge deck layer 1 , and the steel mesh shear structure 3 is embedded in the ultra-high performance concrete layer 2 . The steel mesh shear structure 3 is a double-layer superimposed steel bar composite structure. The double-layer superimposed steel bar composite structure includes a longitudinal bar distribution layer welded on the top surface of the steel bridge deck layer 1 and a transverse bar distribution layer welded above the longitudinal bar distribution layer. The longitudinal bar dis...

Embodiment 2

[0051] A sort of Figure 5 ~ Figure 7 The steel-ultra-high-performance concrete composite deck structure containing the shear structure of the present invention is shown, and the composite deck structure includes the steel bridge deck layer 1 below and the ultra-high-performance concrete layer poured on the steel bridge deck layer 1 2. The lower part of the steel bridge deck layer 1 is provided with longitudinal rib webs 8 , and the steel mesh shear structure 3 is welded above the steel bridge deck layer 1 , and the steel mesh shear structure 3 is embedded in the ultra-high performance concrete layer 2 . The steel mesh shear structure 3 is a double-layer superimposed steel bar composite structure. The double-layer superimposed steel bar composite structure includes a longitudinal bar distribution layer welded on the top surface of the steel bridge deck layer 1 and a transverse bar distribution layer welded above the longitudinal bar distribution layer. The longitudinal bar dis...

Embodiment 3

[0058] A sort of Figure 8 ~ Figure 10 The steel-ultra-high-performance concrete composite deck structure containing the shear structure of the present invention is shown, and the composite deck structure includes the steel bridge deck layer 1 below and the ultra-high-performance concrete layer poured on the steel bridge deck layer 1 2. The lower part of the steel bridge deck layer 1 is provided with longitudinal rib webs 8 , and the steel mesh shear structure 3 is welded above the steel bridge deck layer 1 , and the steel mesh shear structure 3 is embedded in the ultra-high performance concrete layer 2 . The steel mesh shear structure 3 is a three-layer superimposed steel bar composite structure. The three-layer superimposed steel bar composite structure includes a transverse reinforcement distribution layer welded on the top surface of the steel bridge deck layer 1, a longitudinal reinforcement distribution layer welded above the transverse reinforcement distribution layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com