Load cell for a scale

A load sensor and circuit board technology, applied in instruments, weighing equipment using elastically deformable parts, detailed information of weighing equipment, etc., can solve the problem of load sensor circuit board not being a material height limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

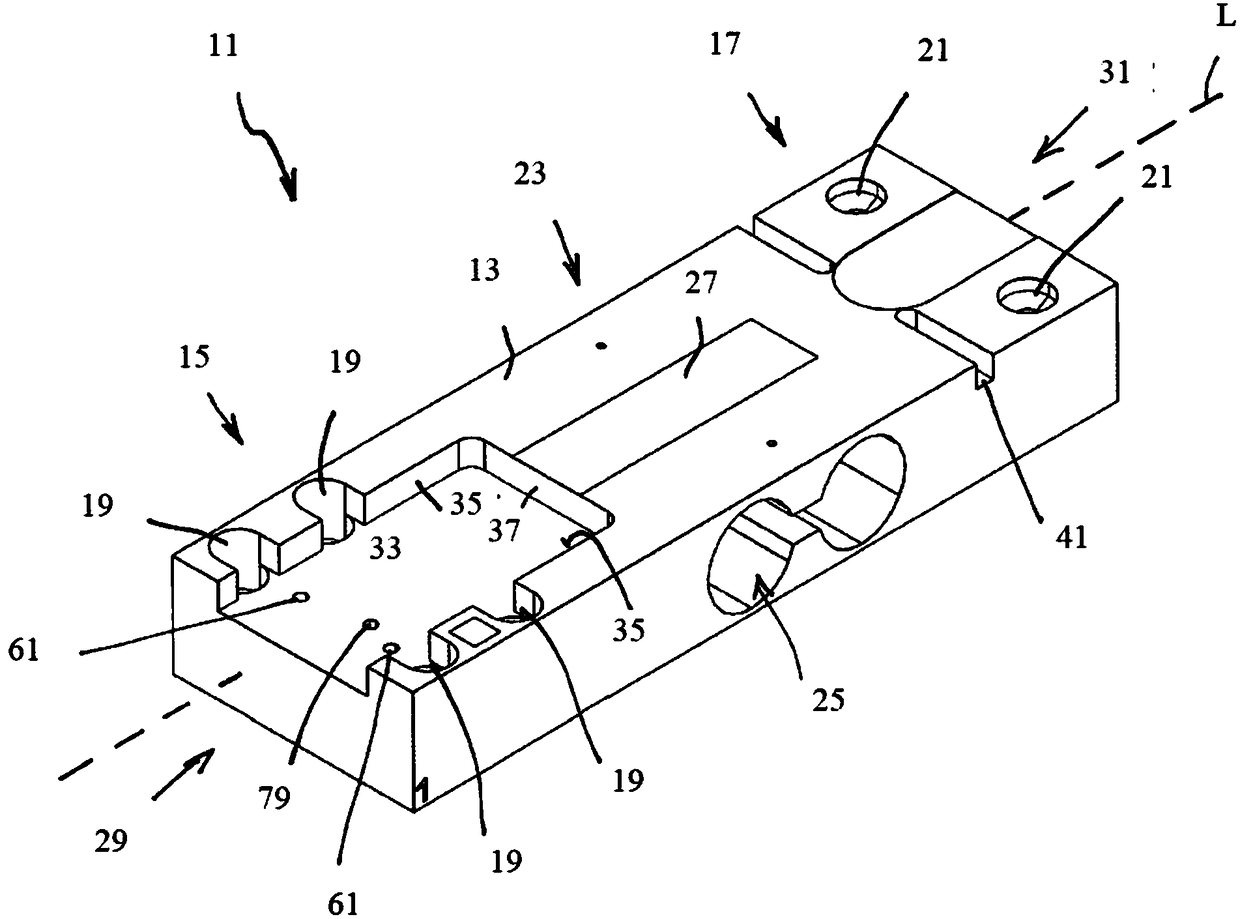

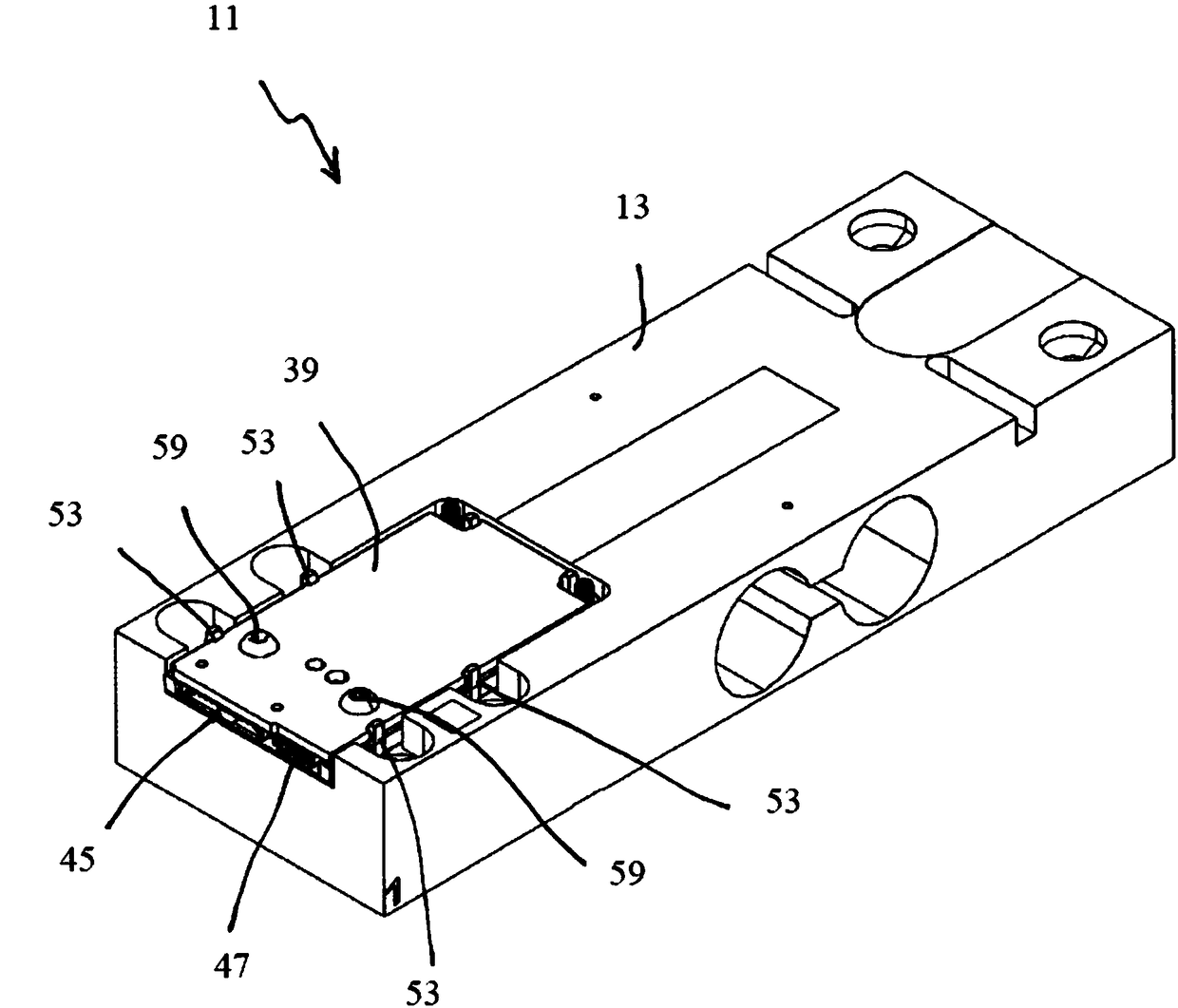

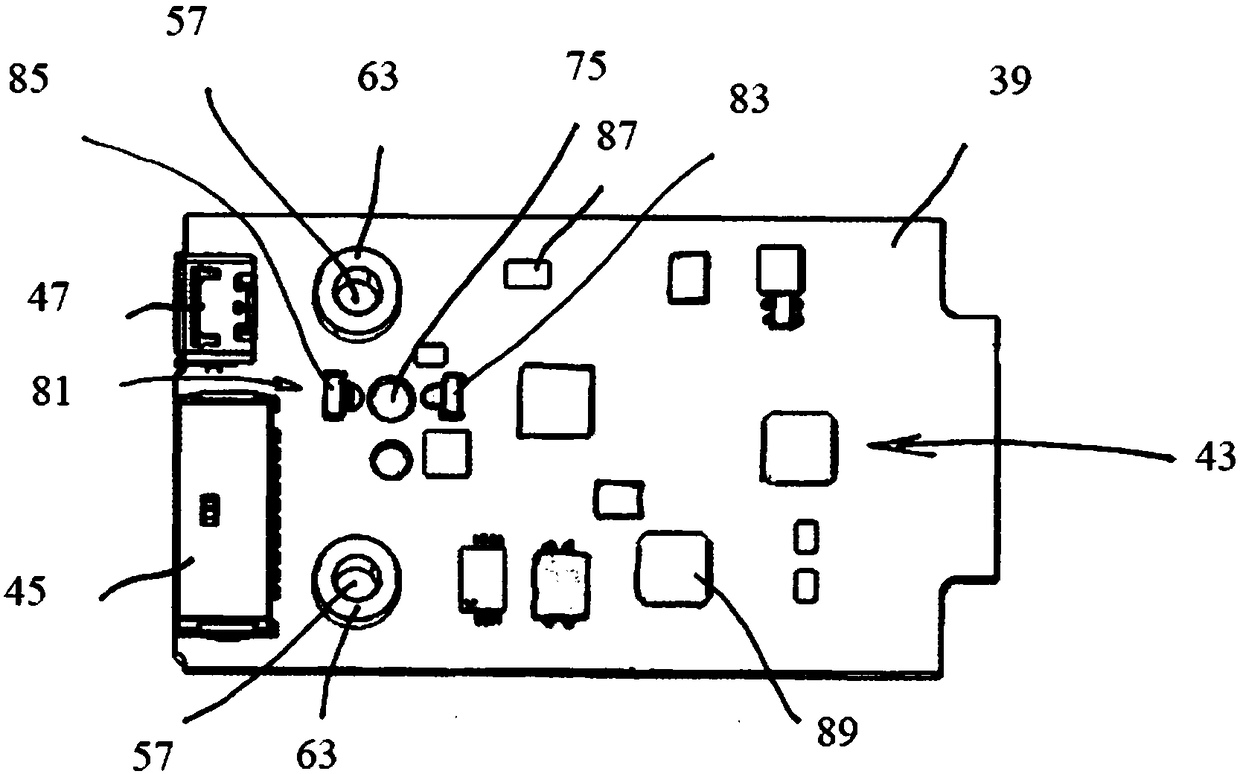

[0071] load cell 11 in figure 1 A balance for calibration is shown in , which comprises a measuring body 13 integrally formed as a block and having a force receiving part 15 and a force introducing part 17 . The force receiver 15 can be fastened via four fastening holes 19 to the fixed part of the scale and the load rail carrying the load plate can be fastened (not shown) to the force introduction via two fastening holes 21 . A joint 23 is provided between the two parts 15 , 17 such that the measuring body 13 acts as a bending rod or beam. To this end, a central channel 25 is formed in the junction 23 ; it is in particular dog-bone-shaped in cross-section and passes completely through the measuring body 13 . The measuring body 13 generally has a longitudinal axis L, an end 29 on the force-receiving side and an end 31 on the force-introducing side. A groove 41 extending perpendicularly to the longitudinal axis L is provided on the upper side of the measuring body 13 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com