Vehicle body structure for battery-replaceable electric vehicle

An electric vehicle and body technology, applied in the field of vehicles, can solve problems such as poor electric exchange plane accuracy, achieve the effects of improving strength and rigidity, ensuring electric exchange accuracy, and improving collision energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

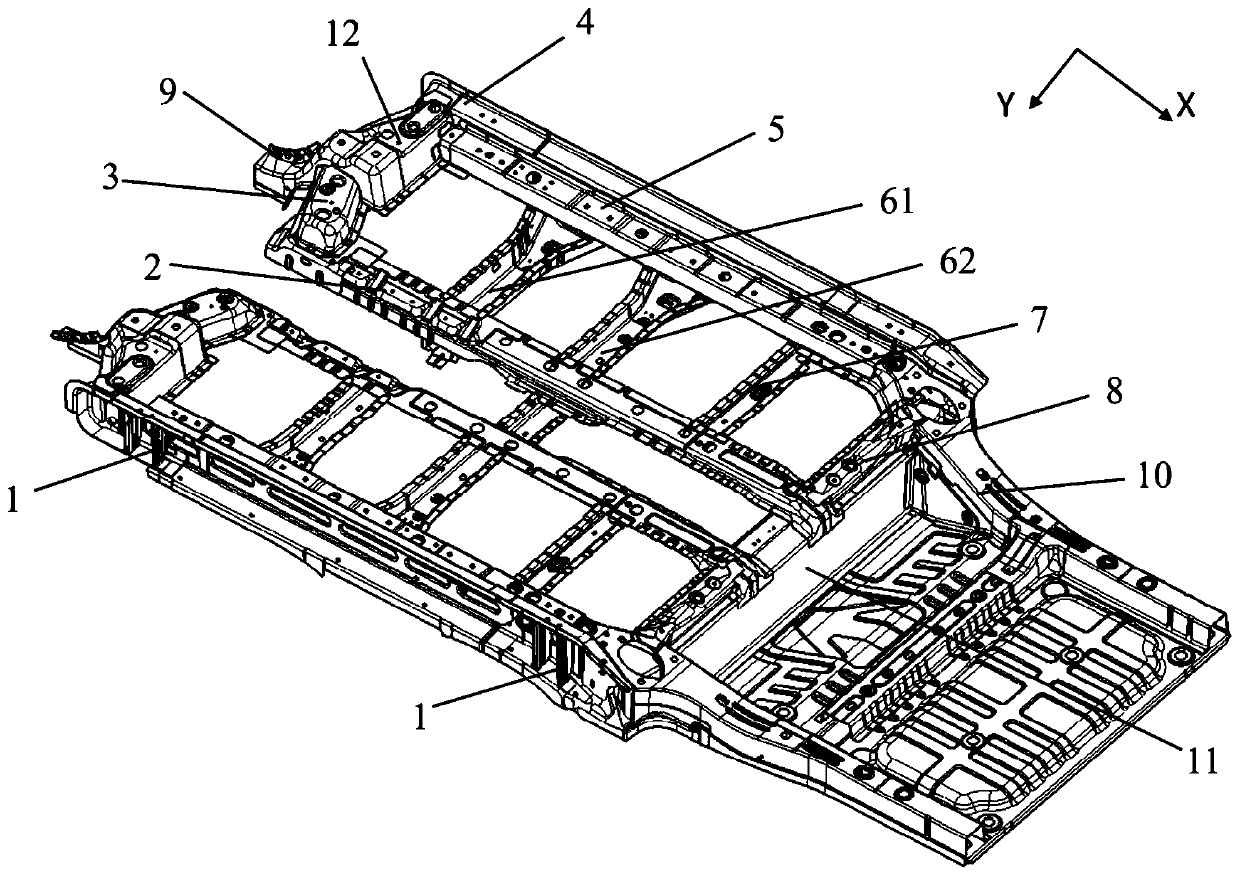

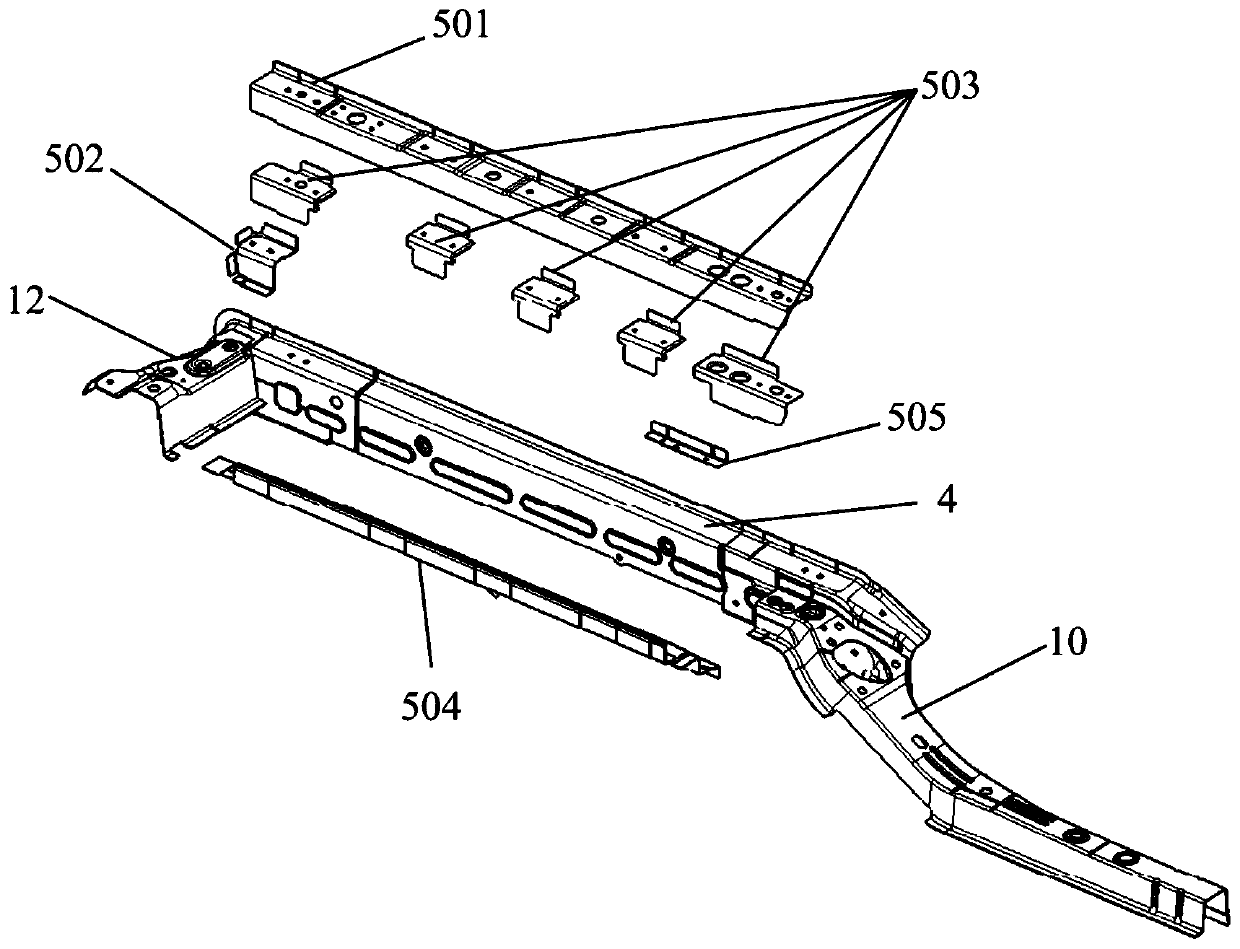

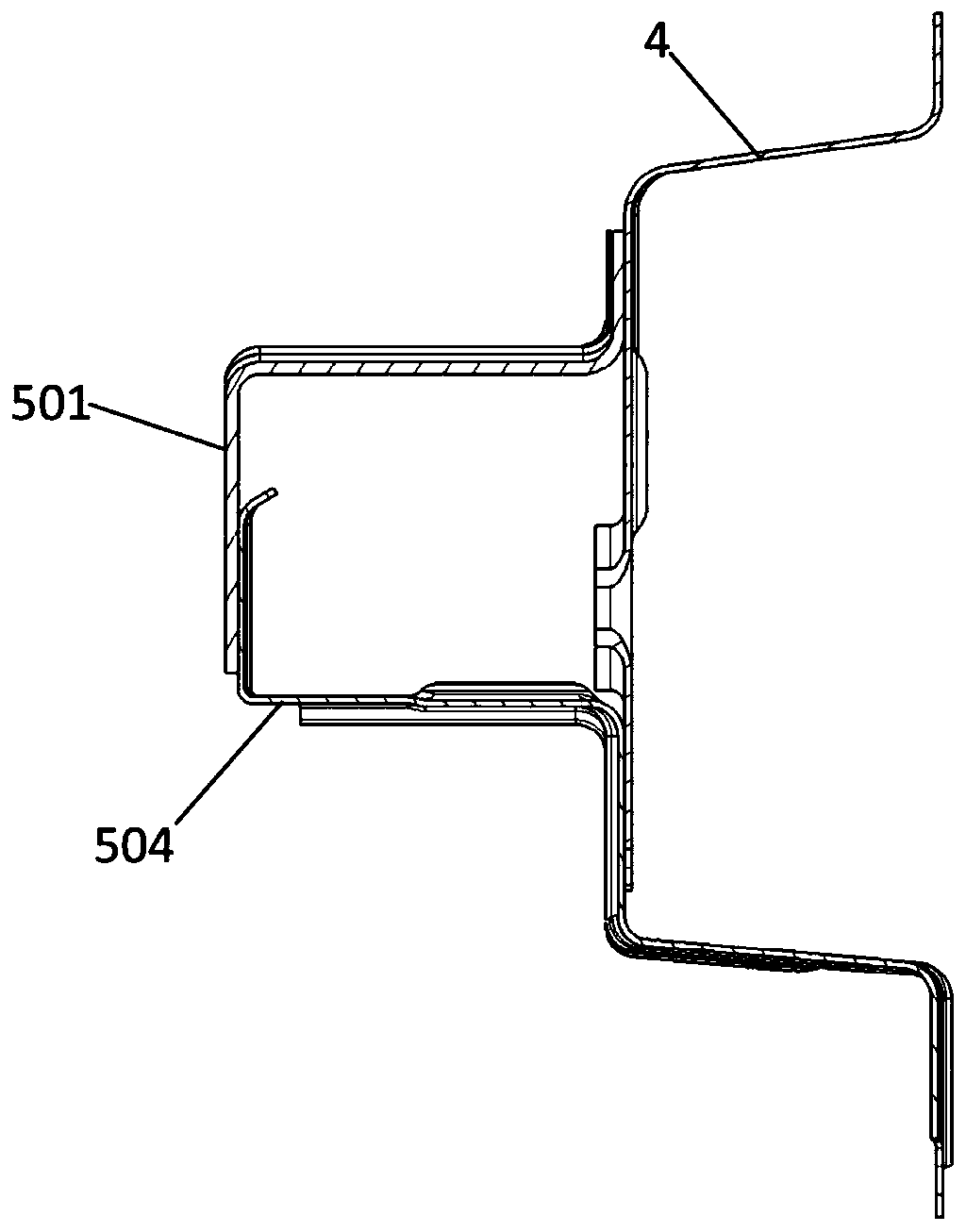

[0048] figure 1 is a structural schematic diagram of a vehicle body structure according to an embodiment of the present invention. figure 1 In the middle, X direction is the longitudinal direction of the vehicle, Y is the lateral direction of the vehicle, +X is the rear side of the vehicle, and +Y is the right side of the vehicle. Such as figure 1 As shown, the present invention provides a vehicle body structure for a swappable electric vehicle. The vehicle body structure is a left-right symmetrical structure and includes multiple longitudinal beams and multiple cross beams. A plurality of longitudinal beams extend longitudinally along the vehicle, and the plurality of longitudinal beams at least include two sill beams 4 located on the left and right sides of the vehicle, two battery replacement longitudinal beams 5 and central channel side reinforcement beams located on the left and right sides of the central channel of the vehicle 2. Each battery-replacing longitudinal bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com