Ultrahigh-performance concrete bridge deck

An ultra-high-performance, concrete slab technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problem of easy failure of bonding between orthotropic steel bridge deck and asphalt wear layer, easy cracking of ordinary concrete bridge deck, and asphalt pavement Avoiding the easy damage of the asphalt pavement layer, avoiding the easy damage of the asphalt pavement layer, solving the fatigue cracking disease, and reducing the maintenance cost in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

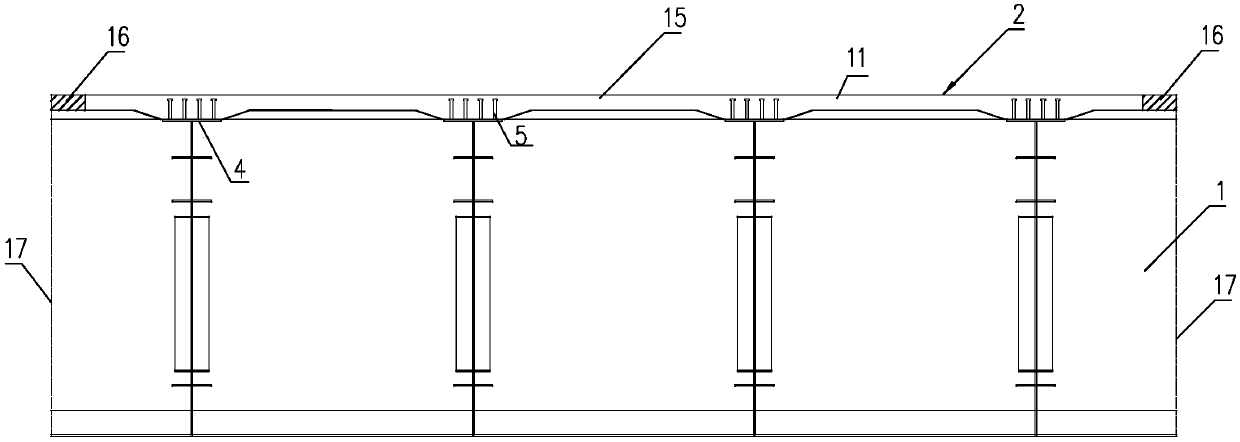

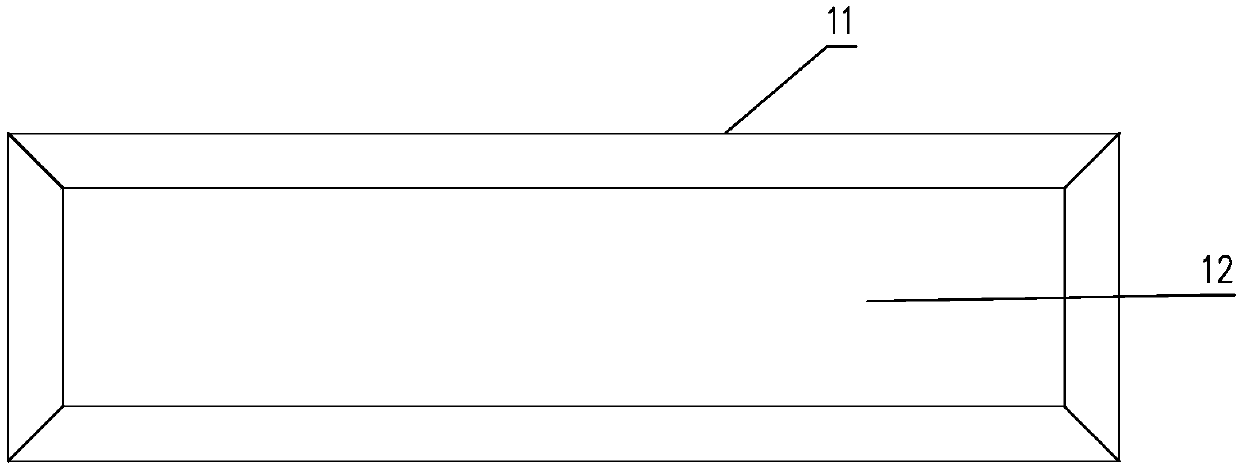

[0040] Such as Figure 1-7 Shown is an ultra-high-performance concrete bridge deck 2 of the present invention, which is formed by connecting ultra-high-performance concrete slabs 11 arranged in an array. The bottom surface of the ultra-high-performance concrete slab 11 is groove-shaped. Groove 12 is the flat quadrangular truncated pyramid shape that is gradually included from top to bottom, see Figure 7 , the ultra-high performance concrete slab 11 is provided with a steel mesh connected by steel bars arranged along the two main directions of stress. In this embodiment, two upper and lower layers of steel mesh are arranged according to the distribution of positive and negative bending moments. The main reinforcement adopts C16-C25 steel bars 7, and the distribution bars in the other direction use C12-C20 steel bars 71. The connecting section between two adjacent ultra-high performance concrete slabs 11 is the connecting section of ultra-high performance concrete slabs. The c...

Embodiment 2

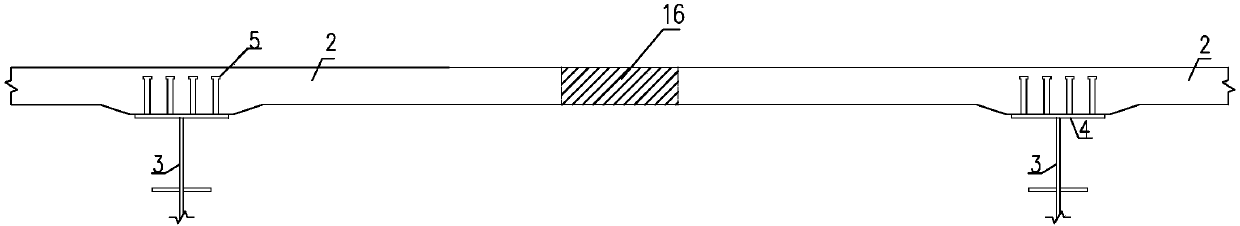

[0051] Such as Figure 8 and 9 As shown, the difference between this embodiment and Embodiment 1 is that the wet joint is located at the mid-span position, each prefabricated section 15 is formed by connecting several complete ultra-high performance concrete slabs 11, and two adjacent prefabricated sections 15 A part of the ultra-high-performance concrete slab 11 is connected through a cast-in-place section 16 to form a complete ultra-high-performance concrete slab 11. The cast-in-place section 16 uses a steel plate 9 with a shear stud 5 as a formwork for wet joints and then casts an ultra-high-performance concrete slab. After the concrete is formed, therefore, local UHPC composite bridge decks with shear nails can also be used for the cast-in-place sections within the range of about 500mm on both sides of the construction joint. When the wet joints use UHPC composite bridge decks with steel plates with shear nails at the bottom , its steel plate can also be used as a templat...

Embodiment 3

[0053] Such as Figure 10 and 11 As shown, the difference between this embodiment and Embodiment 1 is that the wet joints are located at the upper flanges 4 of the beams and longitudinal beams 3, and each prefabricated section 15 is connected by several complete ultra-high performance concrete slabs 11. The cast-in-place section 16 is an ultra-high performance concrete slab connection section connected with the main beam 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com