Steel box girder reinforcing structure and method

A technology for strengthening structures and steel box girders, which is used in bridge reinforcement, bridges, bridge maintenance, etc. It can solve the problem that the improvement effect of crack tip stress is difficult to evaluate, reduce structural rigidity and ultimate bearing capacity, and improve the stress of diaphragm base material. and other problems, to achieve the effect of convenient reinforcement design and construction, inhibition of crack propagation, simple and lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

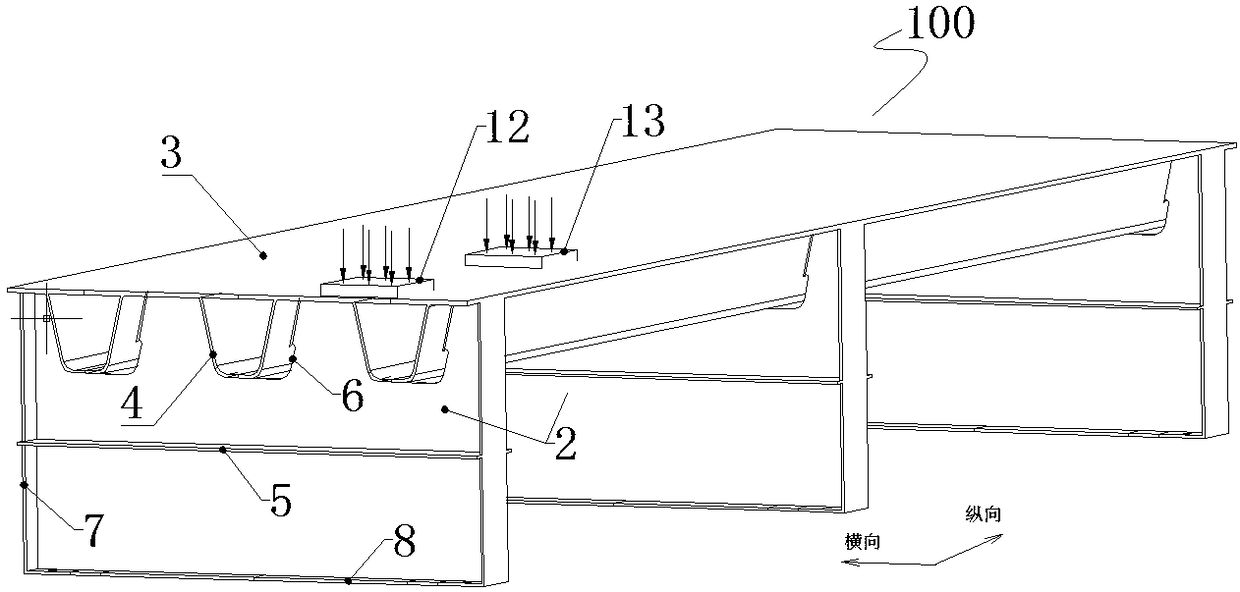

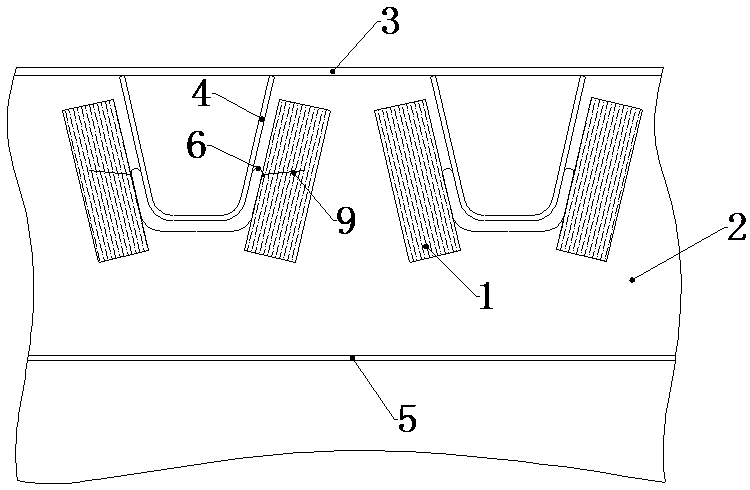

[0052] like Figure 1~3 As shown, a steel box girder reinforcement structure includes a box girder body 100, and the box girder body 100 includes a transverse diaphragm 2 arranged at intervals, a top plate 3, a bottom plate 8, and vertical stiffeners 7 arranged perpendicular to both ends of the bottom plate 8 , the through notch 21 opened on the transverse partition plate 2 , and the U rib 4 fixed in the notch 21 . The diaphragm 2 is fixed on the bottom plate 8 and fixed between two vertical stiffeners 7 . The top plate 3 is fixed on the top of the U-rib 4 and the vertical stiffener 7 , and a horizontal stiffener 5 is provided in the middle of the diaphragm 2 .

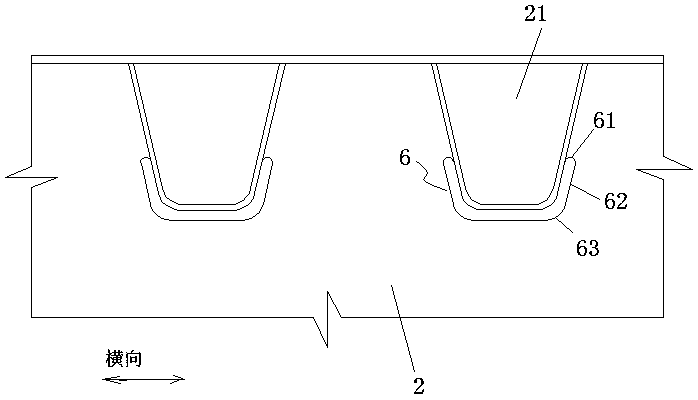

[0053] Arc-shaped notches 6 are formed on both sides of the notch 21 , and there is a gap between the edges of the arc-shaped notches 6 and the U rib 4 . The arc-shaped notch 6 includes an upward convex arc section 61 extending laterally on the side of the notch 21, an oblique edge section 62 connected with the upwa...

Embodiment 2

[0079] like Figure 7 As shown, Example 1 is repeated, the difference is that the reinforcing plate 1 is a special-shaped plate, and is a laminated plate, including a first plate 10 for being arranged between two adjacent arc-shaped gaps 6, And the second plate 11 for being arranged on one side of the arc-shaped notch 6 . The shapes of both sides of the first plate 10 match the shape of the arc-shaped notch 6 . Only one side of the second plate 11 matches the shape of the arc-shaped notch 6 .

[0080] The first plate 10 is suitable for the situation that the regions of the diaphragm 2 near two adjacent arc-shaped notches 6 need to be reinforced. The second plate 11 is suitable for the situation where only one area of the diaphragm 2 near the arc-shaped notch 6 needs to be reinforced.

Embodiment 3

[0082] like Figure 8-9As shown, repeat Example 2, the difference is: the bolt 15 between the reinforcing plate 1 and the diaphragm 2 is reinforced twice with the annular steel gasket 14, and the annular steel gasket 14 is pressed on the reinforcing plate 1 four corners, and fastened to the diaphragm 2 with bolts 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com