Boring bar special for machining deep hole and inner groove

A groove machining and deep hole technology, applied in boring bars and other directions, can solve the problems of not being suitable for machining deep hole multi-layer annular inner grooves, unable to ensure the axial dimensional accuracy of annular grooves, and not suitable for deep hole machining with small diameters. Achieve the effect of increasing stiffness, reducing deformation, and improving local stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

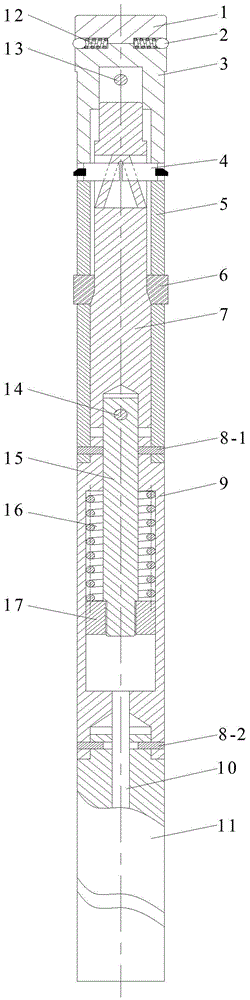

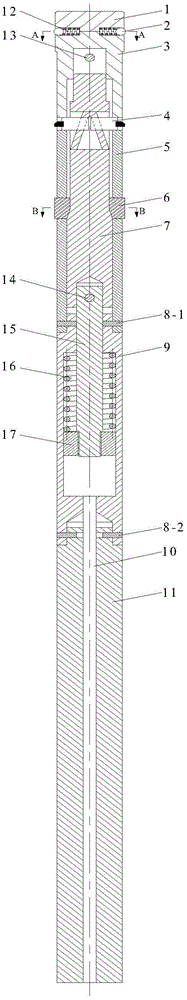

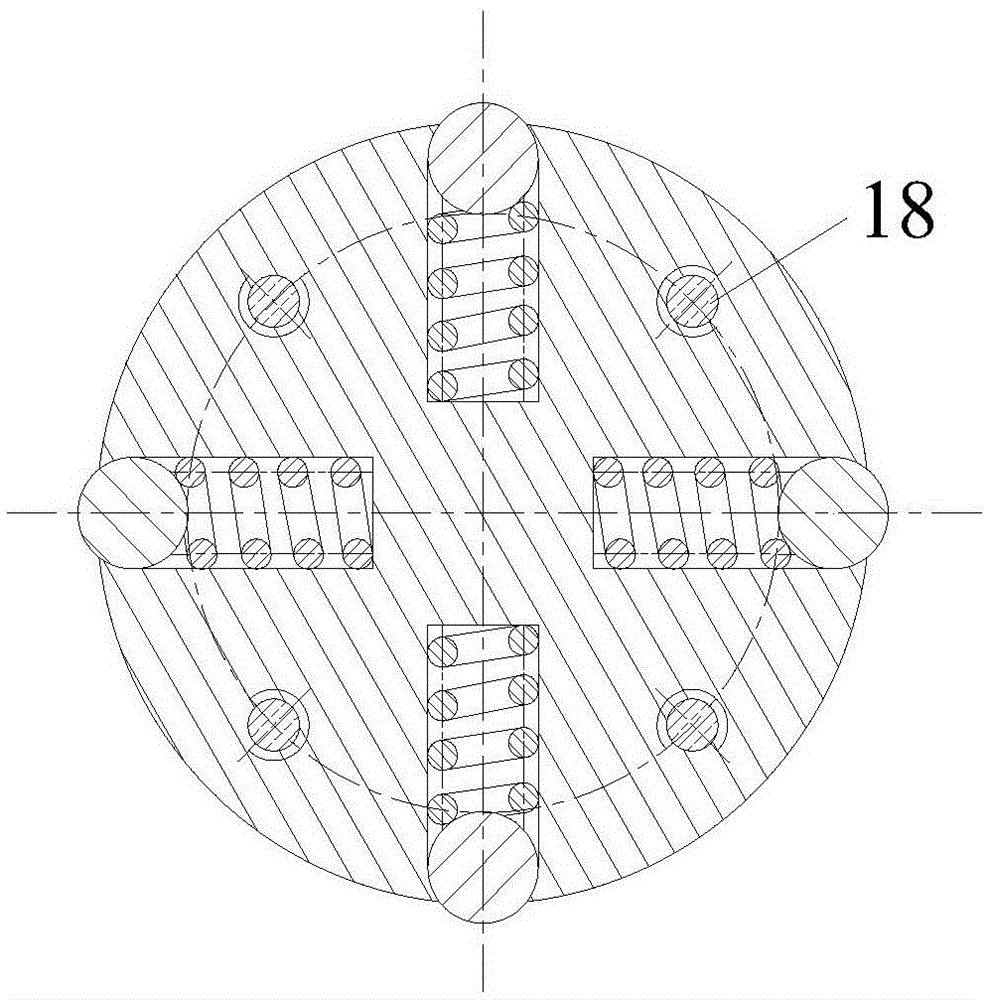

[0038] figure 1 It is a schematic diagram of the overall structure of the special boring bar for segmented deep hole inner groove processing with guide support of the present invention. It is mainly suitable for boring inner grooves of deep and long holes with small diameters, and can also be used for boring inner walls of deep holes. The length to diameter ratio of the boring bar is 18:1, and the diameter of the main body of the tool bar is 20mm. The special boring bar is composed of a guide support part, a cutter head part, a tool feed and retract mechanism, a tool bar part and a hydraulic drive part. The guide support part can provide support for the special boring bar and improve the local rigidity of the cutter head. The tool holder part is made of high elastic modulus material, which can further improve the overall rigidity of the cutter holder.

[0039] The assembly process of the special boring bar of the present invention is as follows: firstly, after connecting the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com