Reinforcing device for rear body of vehicle

A reinforcement device and rear body technology, applied to vehicle components, transportation and packaging, superstructure, etc., can solve the problems of insufficient local rigidity at the water tank, poor ride comfort performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

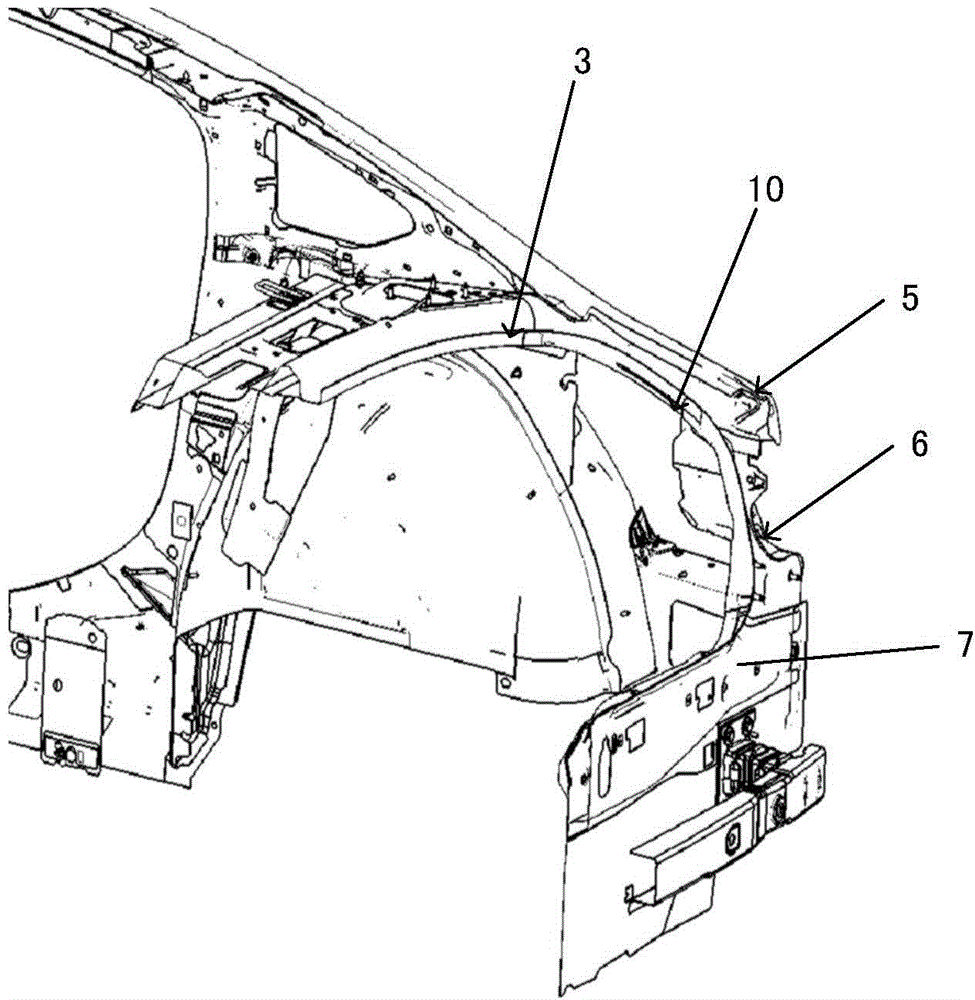

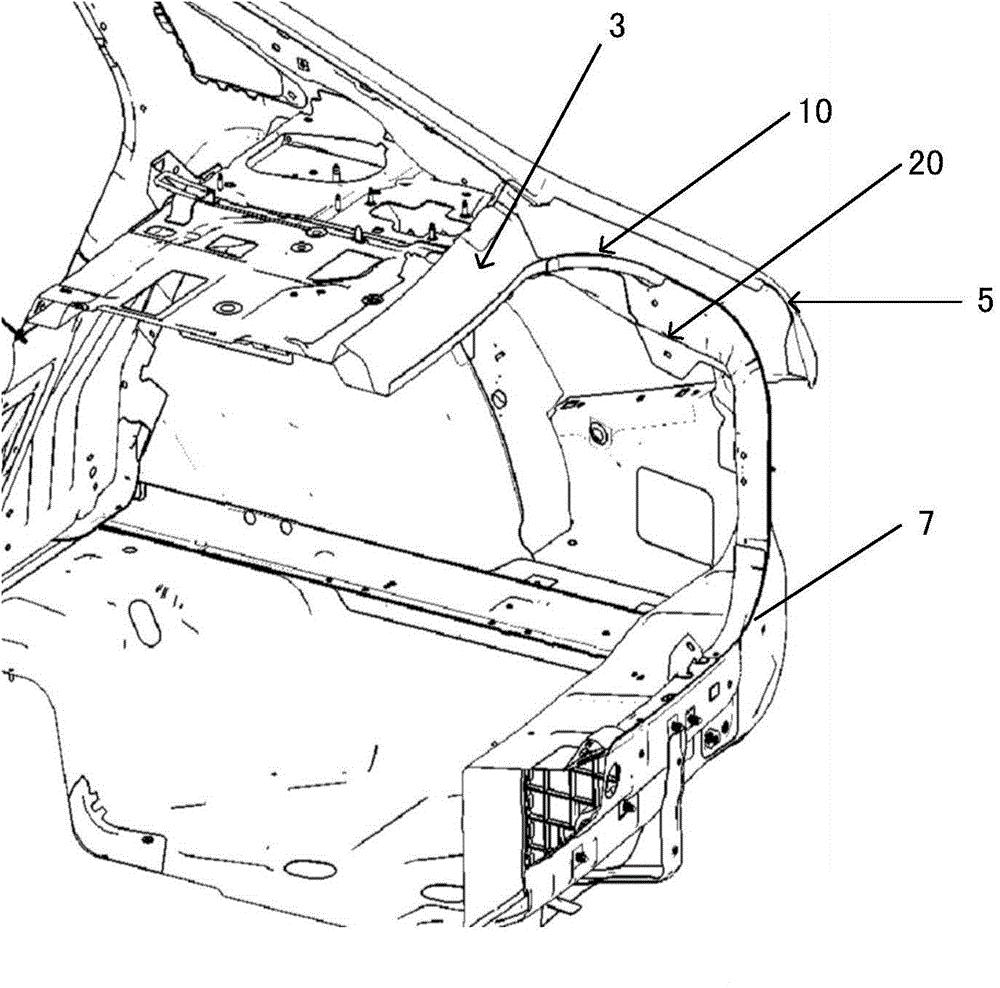

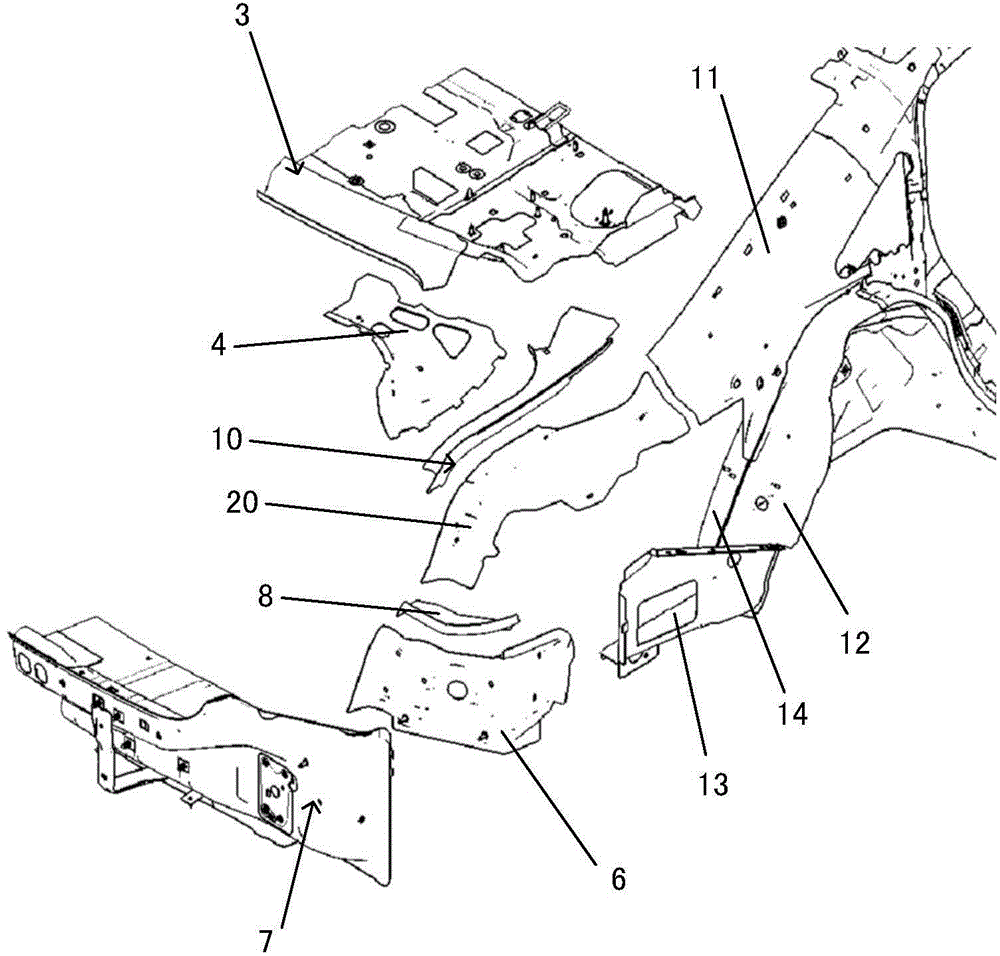

[0020] According to an embodiment of the present invention, such as figure 2 As shown, a metal reinforcement plate 20 is provided on the gutter structure of the rear body of the vehicle, and the reinforcement plate 20 is fixedly connected to the rear shelf assembly 3, the gutter member 10, the tail lamp seat plate 6 and the tailgate assembly 7 superior. For specific components, see image 3 , the components related to the gutter member 10 and the reinforcement plate 20 include the rear shelf assembly 3 and the rear shelf side connection plate 4, the C-pillar inner panel 11, the rear end 12 of the wheelhouse outer panel, the wheelhouse inner panel 14, the rear Fender cover plate 13, tail light cover plate 8, tail light seat plate 6 and rear panel assembly 7.

[0021] exist Figure 4 and Figure 5A , Figures B and 5C, showing the front part of the reinforcement panel 20, the reinforcement panel is connected to the C-pillar inner panel 11, as Figure 5A shown. In the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com