All-region bionic wheel of off-road vehicle

An off-road vehicle, all-region technology, applied in the field of tire tread pattern structure design, can solve problems such as low adhesion on low-adhesion roads, and achieve the effects of ensuring performance, increasing friction, and improving driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Describe the present invention below in conjunction with accompanying drawing.

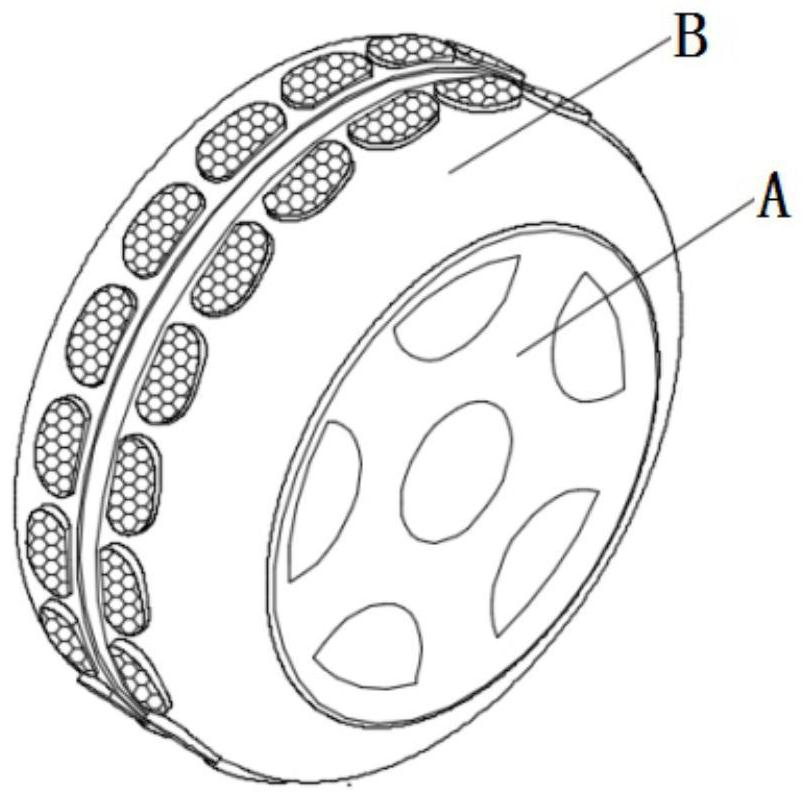

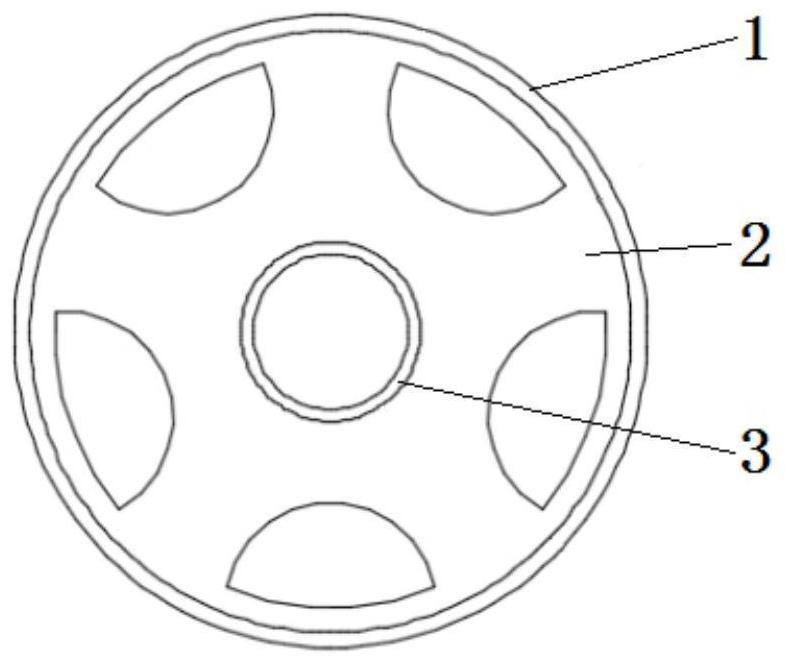

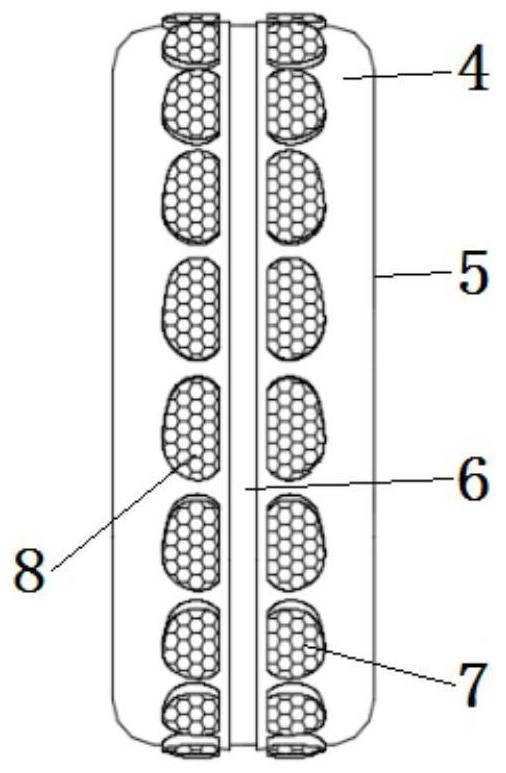

[0029] like Figure 1 to Figure 3 As shown, a kind of off-road vehicle all-terrain bionic wheel of the present invention is made up of wheel hub A and tire B, and described wheel hub A is made up of rim 1, wheel spoke group 2 and inner wheel rim 3, and wheel rim 1 passes through the 4- 6 spokes are fixedly connected to the inner rim 3; the tire B is composed of a tread 4 and a sidewall 5, wherein a groove 6 is arranged at the center of the circumference of the tread 4, and a pattern block is arranged on one side of the groove 6 Group I7, pattern block group II8 is provided on the other side of groove 6, pattern block group I7 and pattern block group II8 are both composed of 30-36 pattern blocks; tire side 5 of tire B is fixedly connected to rim 1 of wheel hub A.

[0030] like Figure 4 and Figure 5 As shown, in the state of looking down, the outer contour line of each pattern block is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com