Large plane panel deformation control and restoration method based on local rigidity enhancement

A technology of aircraft siding and reset method, which is applied in aircraft assembly, aircraft parts, ground installations, etc., and can solve problems such as large stress, low precision, and impact on aircraft fatigue strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

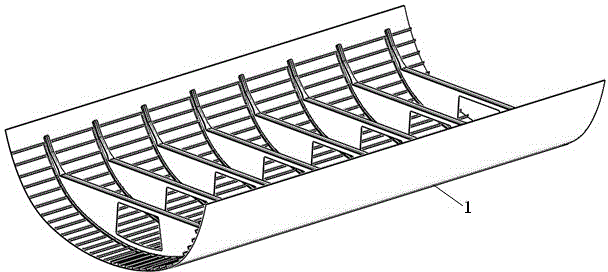

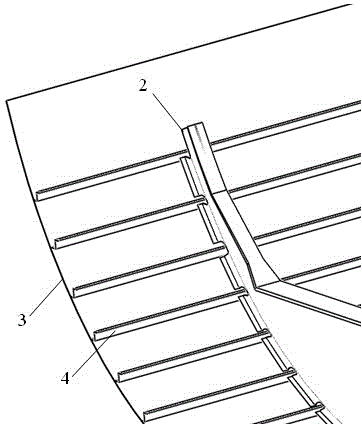

[0059] Such as figure 1 , figure 2 As shown, the large aircraft panel 1 is mainly composed of parts such as a bulkhead 2, a skin 3, and a stringer 4.

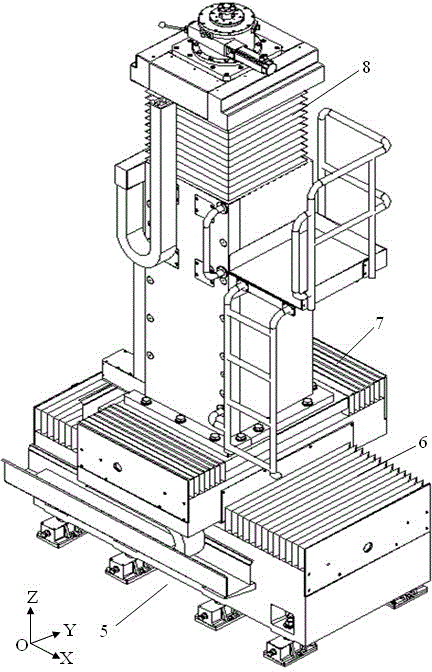

[0060] Such as image 3 As shown, the numerical control positioner is mainly composed of X-axis 6 , Y-axis 7 , Z-axis 8 and other parts, and each axis can move independently, and can be manipulated and controlled by the control system computer 27 .

[0061] Such as Figure 4 As shown, the sub-figures A, B, and C use thick solid lines to represent the deformation of the large aircraft panel 1, where A is the deformation of the large aircraft panel 1 before the process joint 9 is installed, and the deformation is relatively large and irregular ; B is that after the process joint 9 is installed on the wall 1 of the large aircraft, its deformation has been effectively suppressed, and it is relatively regular. 1, and through the coordinated movement of the numerical control locator group 11, the deformed reset is realized.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com