Chloridion-corrosion resistant concrete synergist and production technology thereof

A technology of concrete synergist and chloride ion corrosion, applied in the production process of concrete synergist, concrete synergist, significantly improving the anti-seawater corrosion of concrete and improving the comprehensive performance of concrete in the field of admixtures, which can solve the loss of slump Large, anti-chloride ion performance, corrosion resistance, poor seepage and water resistance, endangering the safety of large structures, etc., to achieve the effect of reducing slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

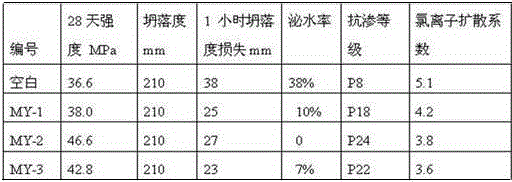

Embodiment 1

[0019] The weight ratio of various substances in the synergist is as follows: anti-bleeding component 709g, anti-seepage and waterproof component 100g, reinforcing component 80g, dispersing component 60g, air-entraining component 6g, compounding component 45g. Mix and stir to make a synergist. The dosage of synergist is 0.6%, and the test is carried out according to Table 1, and the results are shown in Table 2.

[0020] The slump loss in the MY-1 test is 13mm less than that in the blank test, that is, 34.2%, the bleeding is reduced from 38% to 10%, the impermeability level is increased by P18, the chloride ion diffusion coefficient is reduced from 5.1 to 4.2, and the cement is saved per cubic meter of concrete. 40 kg. The 28-day strength is slightly higher than that of blank concrete.

[0021] The mix ratio of MY-2 remains unchanged, and 0.6% synergist is added, and the test slump loss is 11mm less than that of the blank test, that is, 28.9%.

[0022] Bleeding was reduced ...

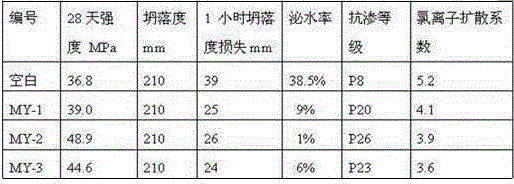

Embodiment 2

[0027] The weight ratio of various substances in the synergist is as follows: anti-bleeding component 717g, anti-seepage and waterproof component 85g, reinforcing component 95g, dispersing component 50g, air-entraining component 8g, compounding component 45g. Mix and stir to make a synergist. The dosage of synergist is 0.6%, and the test is carried out according to Table 1, and the results are shown in Table 3.

[0028] The slump loss of the MY-1 test is 18mm less than that of the blank test, which is 45%, the bleeding is reduced from 39% to 12%, the impermeability level is increased to P17, and the chloride ion diffusion coefficient is reduced from 5.2 to 4.3. Saved 40 kg. The 28-day strength is significantly higher than that of blank concrete.

[0029] The mix ratio of MY-2 remains the same, 0.6% synergist is added, the test slump loss is 16mm less than that of the blank test, that is, 40%, the bleeding is reduced from 39% to 2%, the impermeability level is increased to P2...

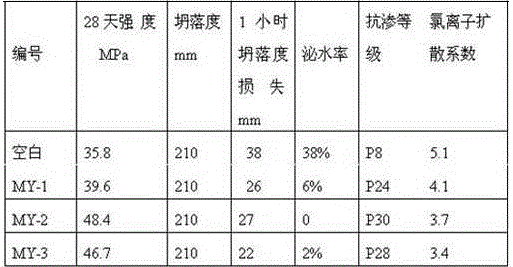

Embodiment 3

[0034] The weight ratio of various substances in the synergist is as follows: anti-bleeding component 665g, anti-seepage and waterproof component 150g, reinforcing component 105g, dispersing component 40g, air-entraining component 10g, compounding component 30g. Mix and stir to make a synergist. The dosage of synergist is 0.6%, and the test is carried out according to Table 1, and the results are shown in Table 3.

[0035] The slump loss of the MY-1 test is 12mm less than that of the blank test, that is, 31.6%, the bleeding is reduced from 38% to 6%, the impermeability level is increased to P24, and the chloride ion diffusion coefficient is reduced from 5.1 to 4.1. Cement saved 40 kg. The 28-day strength is significantly higher than that of blank concrete.

[0036] The mix ratio of MY-2 remains unchanged, and 0.6% synergist is added, and the test slump loss is 11mm less than that of the blank test, that is, 28.9%.

[0037] Bleeding is reduced from 38% to 0%, the impermeabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com