Epitaxial wafer for inverted LED chip and fabrication method of epitaxial wafer

A technology of LED chips and epitaxial wafers, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem that the current expansion ability affects the luminous efficiency and yield of the LED epitaxial structure, so as to enhance the current expansion ability, increase the injection efficiency, manufacture simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Preparation process:

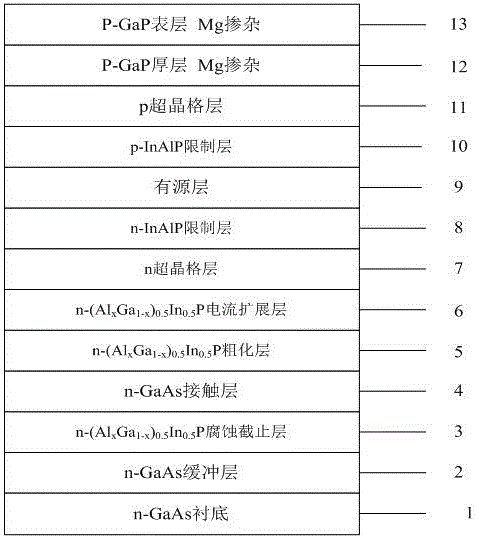

[0022] like figure 1 As shown, the n-GaAs buffer layer 2 is epitaxially grown from bottom to top on the n-GaAs substrate 1 by metal organic chemical vapor deposition (MOCVD), n-(Al x Ga 1-x ) 0.5 In 0.5 P etch stop layer 3, n-GaAs contact layer 4, n-(Al x Ga 1-x ) 0.5 In 0.5 P roughening layer 5, n-(Al x Ga 1-x ) 0.5 In 0.5 P current spreading layer 6, n-type superlattice layer 7, n-InAlP confinement layer 8, active layer 9, p-InAlP confinement layer 10, p-type superlattice layer 11, p-GaP window layer.

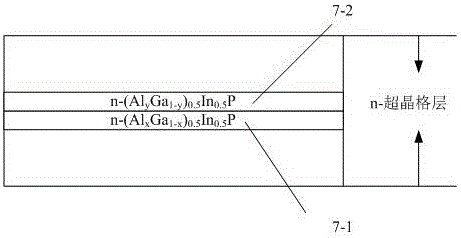

[0023] Wherein, n-type superlattice layer 7 is made of n-(Al x Ga 1-x ) 0.5 In 0.5 P potential well layer and n-(Al y Ga 1-y ) 0.5 In 0.5 The P potential barrier layers are periodically grown and formed, 0.42 h 6 as a source of doping. The thickness of the single periodic superlattice of the n-type superlattice layer is 5nm-20nm.

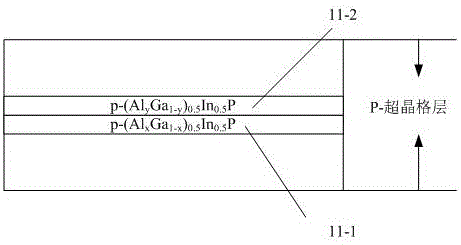

[0024] The p-type superlattice layer 11 is made of p-(Al x Ga 1-x ) 0.5 In 0.5 P potent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com