Al-Ni-Ce-La aluminum-based amorphous alloy and preparation method thereof

An amorphous alloy, aluminum-based technology, applied in the field of metal materials, can solve the problems of poor amorphous formation ability and difficulty of aluminum alloys, and achieve the effects of low cooling rate, improved densification, and simple composition and preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: preparation composition is Al 84 Ni 10 Ce 4 La 2 (x=2, at.%) amorphous alloy

[0039] Step 1: Ingredients

[0040] Select pure metal, according to the nominal composition Al 84 Ni 10 Ce 4 La 2 (x=2, at.%) batching. When batching, it should be mechanically polished to remove the pollution layer on the surface of pure metal raw materials, and then cleaned with a mixed solution of alcohol and acetone and air-dried.

[0041] Step 2: Preparation of master alloy

[0042] The alloy raw material prepared in the first step is smelted 3 to 6 times in a vacuum electric arc furnace, and electromagnetic stirring is performed at the same time to obtain a uniformly smelted master alloy ingot with a vacuum degree of 10 -3Pa; or use a vacuum induction melting furnace to melt the master alloy in an Ar protective atmosphere, and the vacuum degree is 10 -2 Pa;

[0043] The third step: throwing the tape to prepare the amorphous tape

[0044] After the surface of t...

Embodiment 2

[0046] Embodiment 2: preparation composition is Al 84 Ni 9 Ce 6 Amorphous alloy of La(y=1, at.%)

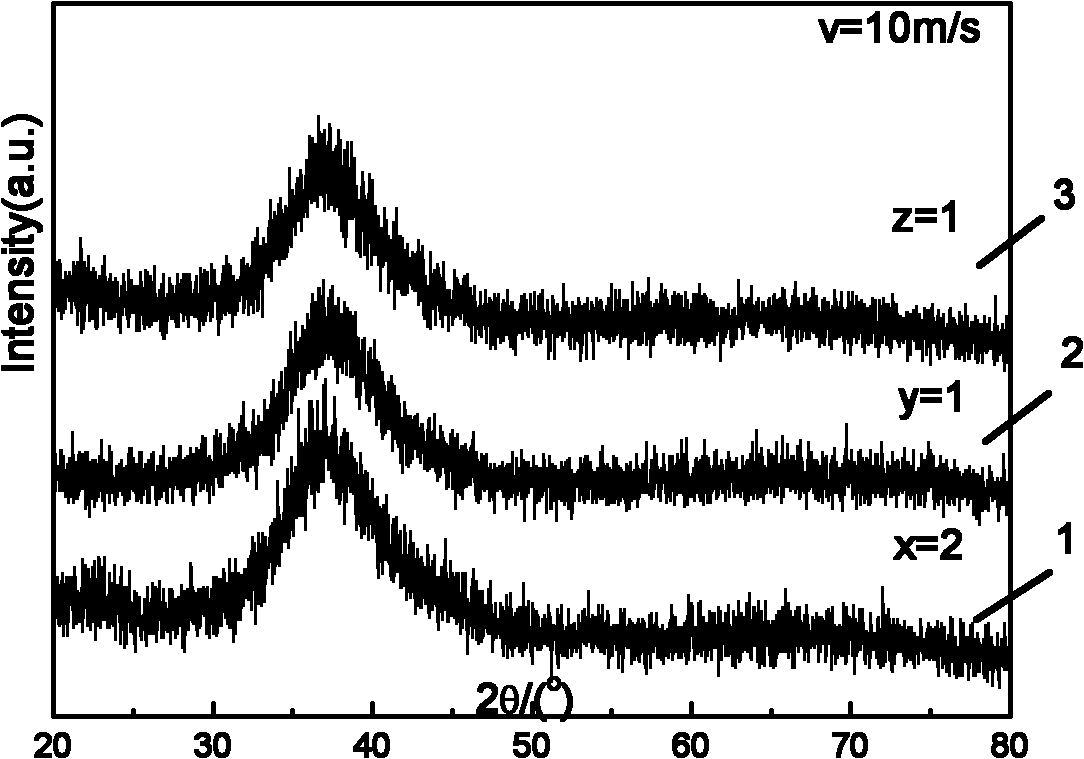

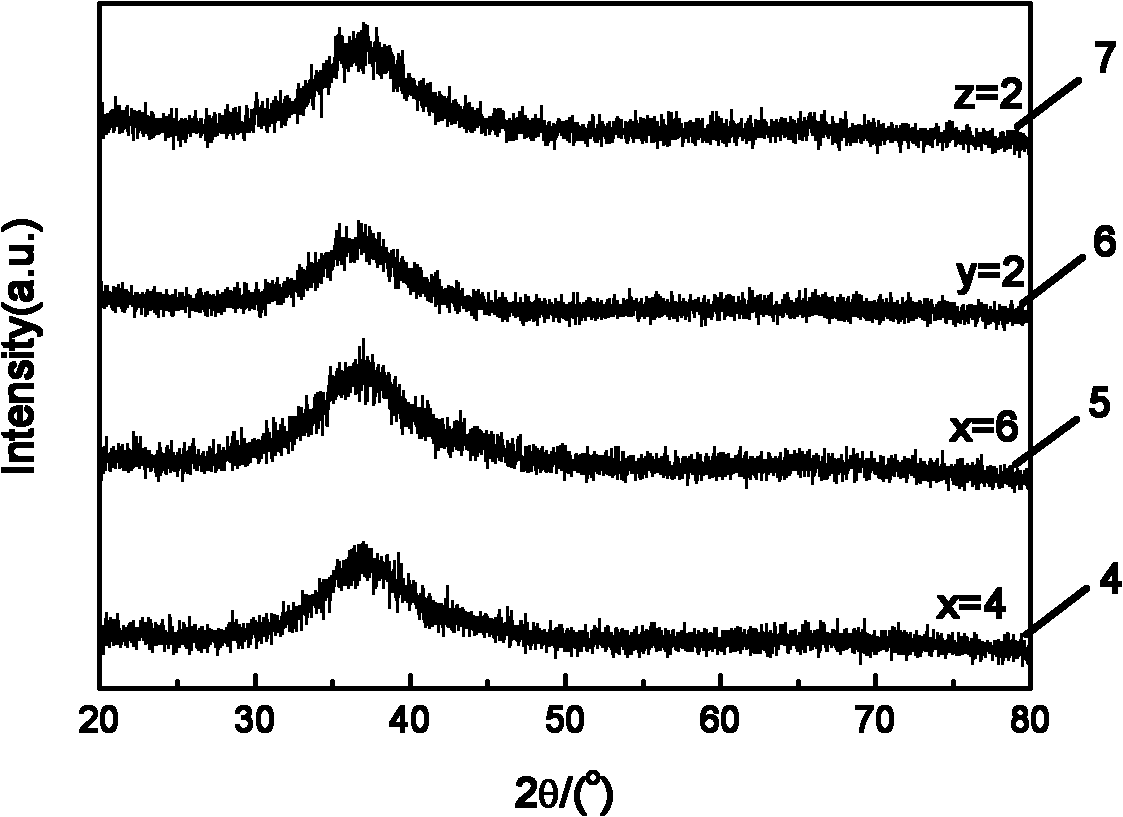

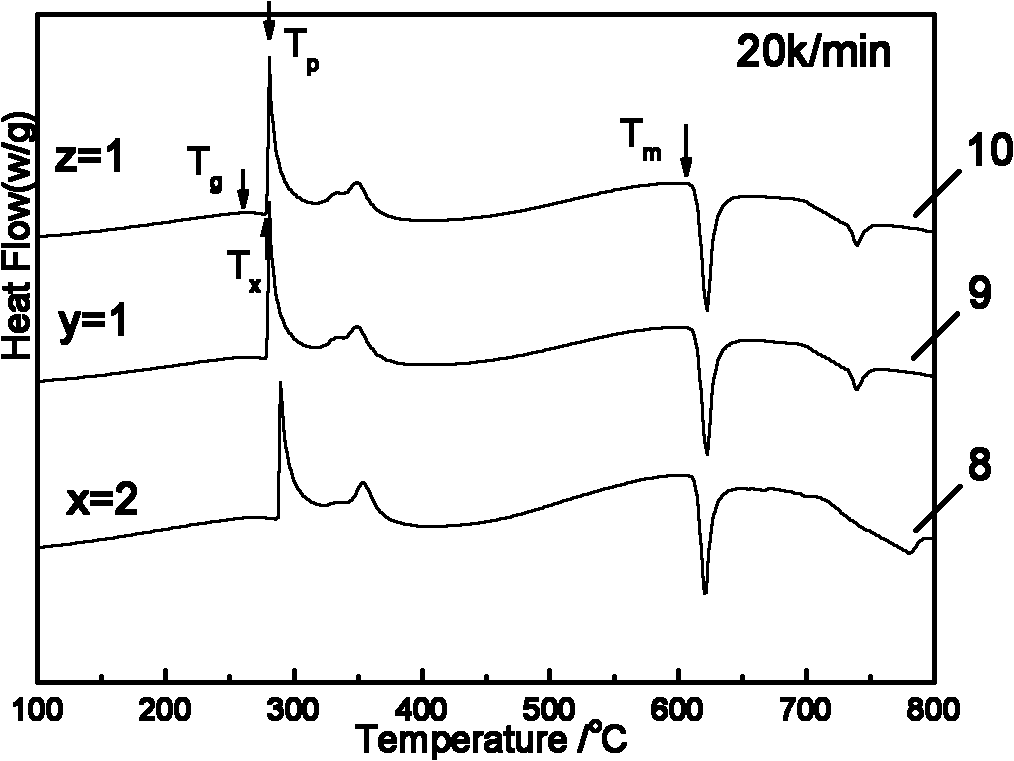

[0047] According to the nominal composition Al 83 Ni 10 Ce 6 La (y=1, at.%) batching, then prepare according to the method and step of example 1 and obtain composition and be Al 84 Ni 9 Ce 6 La amorphous ribbon with a thickness of 105 μm. The results of XRD phase analysis show that the strips prepared are amorphous structure; the results of DSC analysis show that the strips prepared by the present invention have obvious glass transition temperature Tg and wide supercooled liquid phase region ΔTx.

Embodiment 3

[0048] Embodiment 3: preparation composition is Al 83 Ni 10 Ce 6 Amorphous alloy of La(z=1, at.%)

[0049] According to the nominal composition Al 83 Ni 10 Ce 6 La (z=1, at.%) batching, then prepare according to the method and step of example 1 and obtain composition and be Al 83 Ni 10 Ce 6 La amorphous ribbon with a thickness of 100 μm. The XRD phase analysis result shows that the strip material prepared is an amorphous structure; the DSC analysis result shows that the strip material prepared by the present invention has an obvious glass transition temperature T g and a wide subcooled liquid phase region ΔT x .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com