High-hardness high-wear-resistant powder metallurgy high-speed steel

A powder metallurgy and high wear-resistant technology, applied in the field of high-hardness and high-wear-resistant powder metallurgy high-speed steel, can solve the problems of increased cost, powder metallurgy high-speed steel cannot be fully promoted, and powder metallurgy high-speed steel is expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

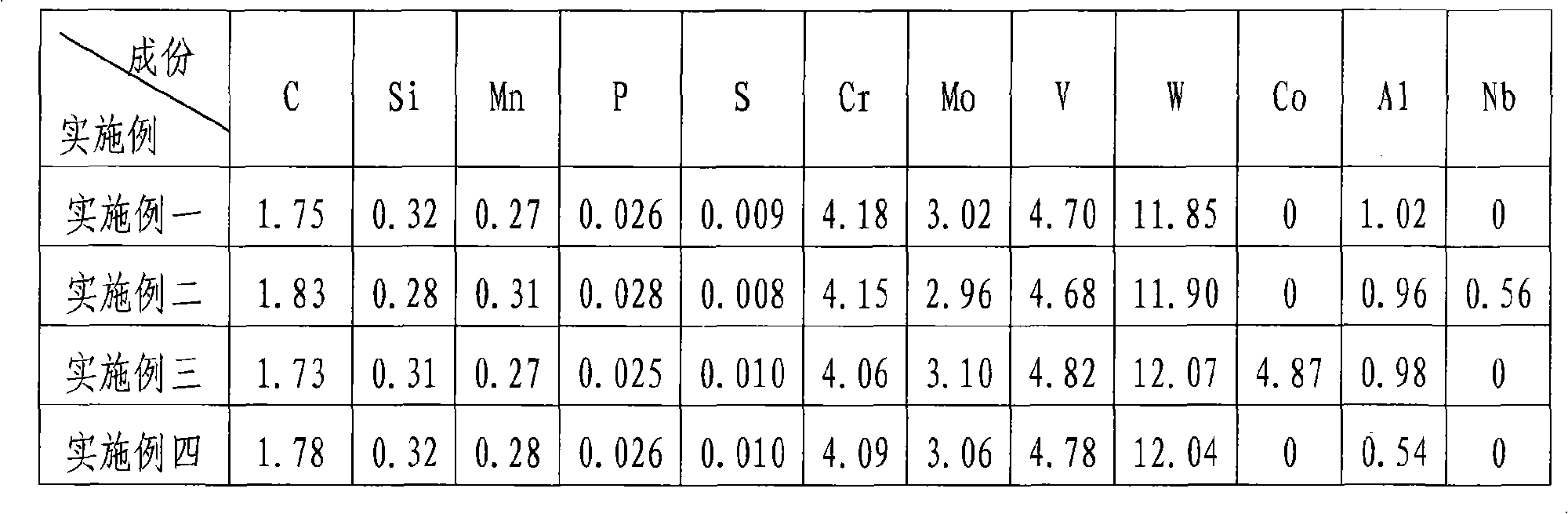

[0022]

[0023] In the preparation process, after the above raw materials are selected according to the corresponding content, 1.5 tons of intermediate frequency + electroslag remelting (or refining outside the furnace) → master alloy → vacuum atomization → sheathing → hot isostatic pressing → precision forging machine Forging→finishing→φ100mm round steel is the finished material.

[0024] Among them, the forging heating temperature of the precision forging machine is 1130-1160°C, the most suitable forging temperature is 950-1050°C, after forging, it should be cooled slowly, and the annealing should be heated to 900°C for 4 hours and then lowered to 720°C at a rate of less than 20°C / hour , furnace cooling, annealing hardness maximum 300HB.

[0025] Forming carbide morphology for embodiment one such as figure 1 , figure 2 As shown, the carbide distribution is uniform and fine, most of the carbides are between 1 and 3 μm, and the maximum is 6 μm.

[0026] After the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com