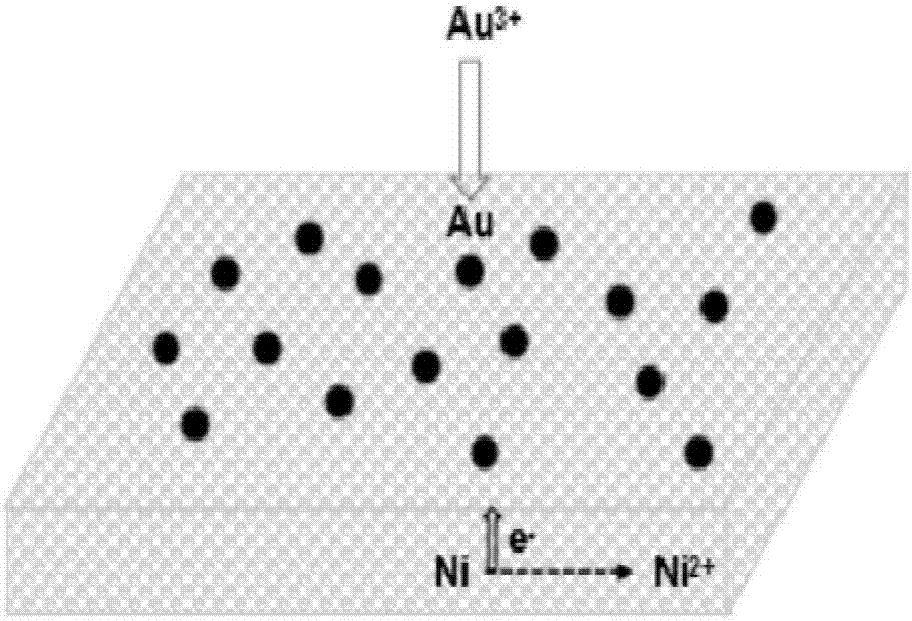

Preparation method of gold-reduced graphene oxide-foamed nickel composite

A composite material, graphene technology, applied in graphene, metal processing equipment, nanotechnology and other directions, can solve the problems of large consumption of graphene oxide, reduced practical value, easy to be damaged, etc., to save consumption, stabilize mass production, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of graphene oxide: take 20ml of concentrated sulfuric acid, stir for 5min under an ice-water bath, then add 1g of graphite powder and stir for 15min; after complete mixing, take 0.5g of sodium nitrate and slowly add it to the above solution to react for 10min; Weigh 1g of potassium permanganate and add it to the above solution and continue to stir for 1h; heat the aqueous solution to 35°C and continue the reaction for 40min; continue to raise the temperature to 80°C, add 40ml of deionized water, and stir for 40min; after the high temperature reaction is over , get 15ml of hydrogen peroxide and add; after cooling, centrifugal washing is repeated 4 times and dispersed in deionized water, configured into a graphene oxide aqueous solution with a concentration of 0.5mg / mL;

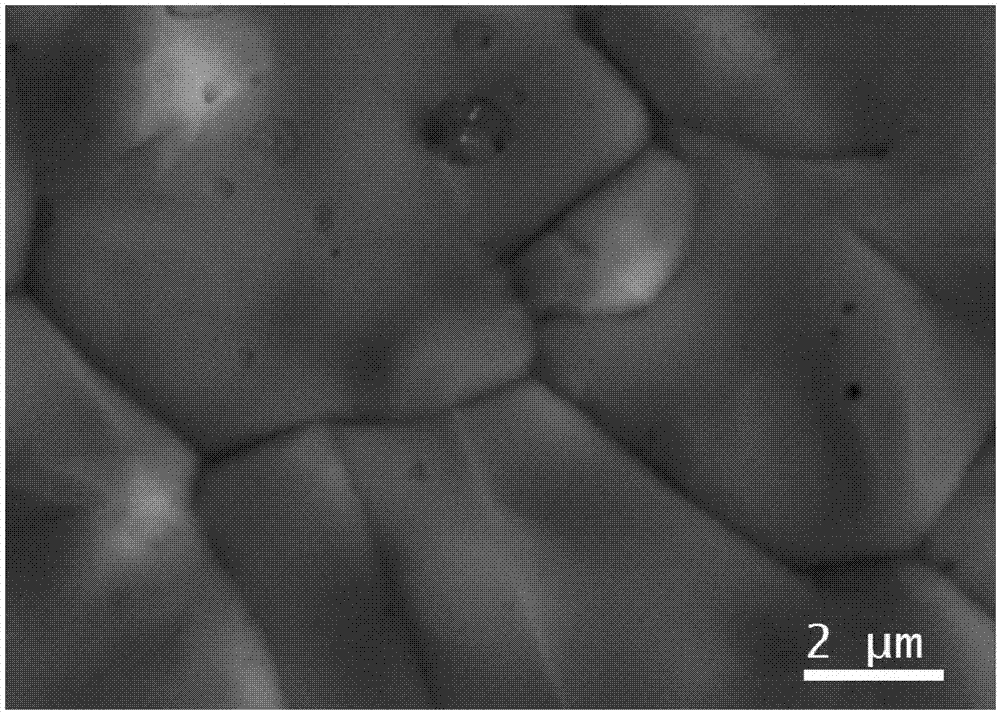

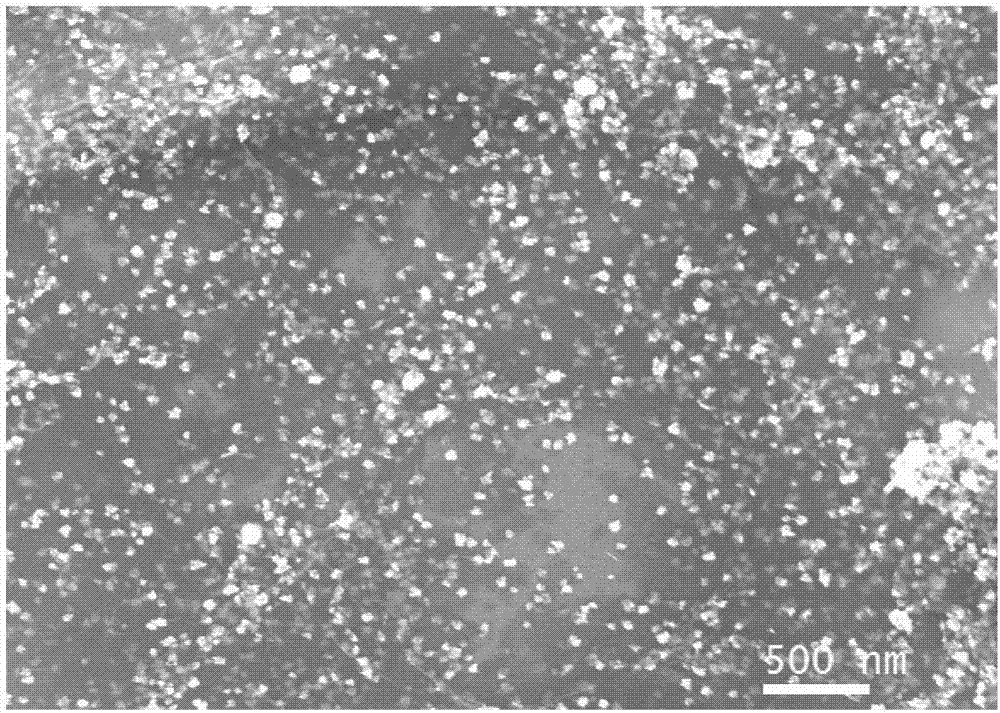

[0027] 2) Preparation of graphene oxide-nickel foam: using nickel foam as the skeleton, the nickel foam was ultrasonically cleaned with acetone, ethanol and deionized water for 10 min succe...

Embodiment 2

[0031] 1) Preparation of graphene oxide: take 30ml of concentrated sulfuric acid, stir for 6min in an ice-water bath, then add 1.5g of graphite powder and stir for 16min; after complete mixing, take 0.6g of sodium nitrate and slowly add it to the above solution to react for 12min ; Weigh 1.5g of potassium permanganate into the above solution and continue to stir for 1.2h; heat the aqueous solution to 37°C and continue the reaction for 45min; continue to raise the temperature to 85°C, add 45ml of deionized water, stir for 45min; high temperature After the reaction, 16ml of hydrogen peroxide was added; after cooling, it was repeatedly centrifuged and washed 5 times and dispersed in deionized water, and configured into a graphene oxide aqueous solution with a concentration of 0.8mg / mL;

[0032] 2) Preparation of graphene oxide-nickel foam: using nickel foam as the skeleton, the nickel foam was ultrasonically cleaned with acetone, ethanol and deionized water for 11 min successively...

Embodiment 3

[0036]1) Preparation of graphene oxide: take 40ml of concentrated sulfuric acid, stir for 8min under an ice-water bath, then add 2g of graphite powder and stir for 18min; after complete mixing, take 0.8g of sodium nitrate and slowly add it to the above solution to react for 17min; Weigh 2g of potassium permanganate and add it to the above solution and continue to stir for 1.5h; heat the aqueous solution to 38°C and continue the reaction for 50min; continue to raise the temperature to 85°C, add 50ml of deionized water, and stir for 50min; the high temperature reaction ends After cooling, 17ml of hydrogen peroxide was added; after cooling, it was centrifuged and washed 5 times and dispersed in deionized water to form a graphene oxide aqueous solution with a concentration of 1.5mg / mL;

[0037] 2) Preparation of graphene oxide-nickel foam: using nickel foam as the skeleton, the nickel foam was ultrasonically cleaned with acetone, ethanol and deionized water for 12 min successively,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com