Composite type reinforced concrete rust inhibitor

A technology of reinforced concrete and rust inhibitor, applied in the field of composite reinforced concrete rust inhibitor, can solve the problems of aggravating rust, consider improving concrete, etc., and achieve the effects of delaying damage, small chloride ion diffusion coefficient, and strong destructive ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

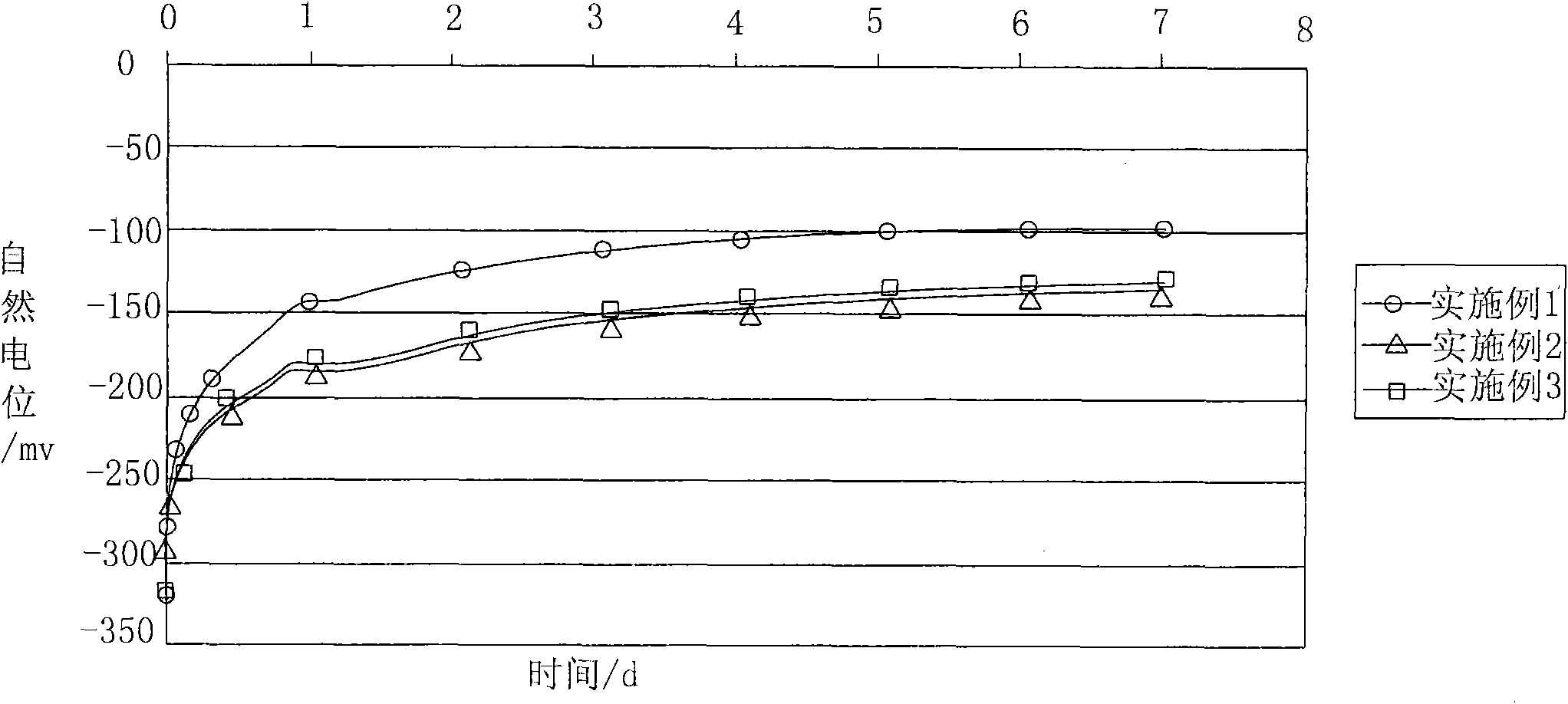

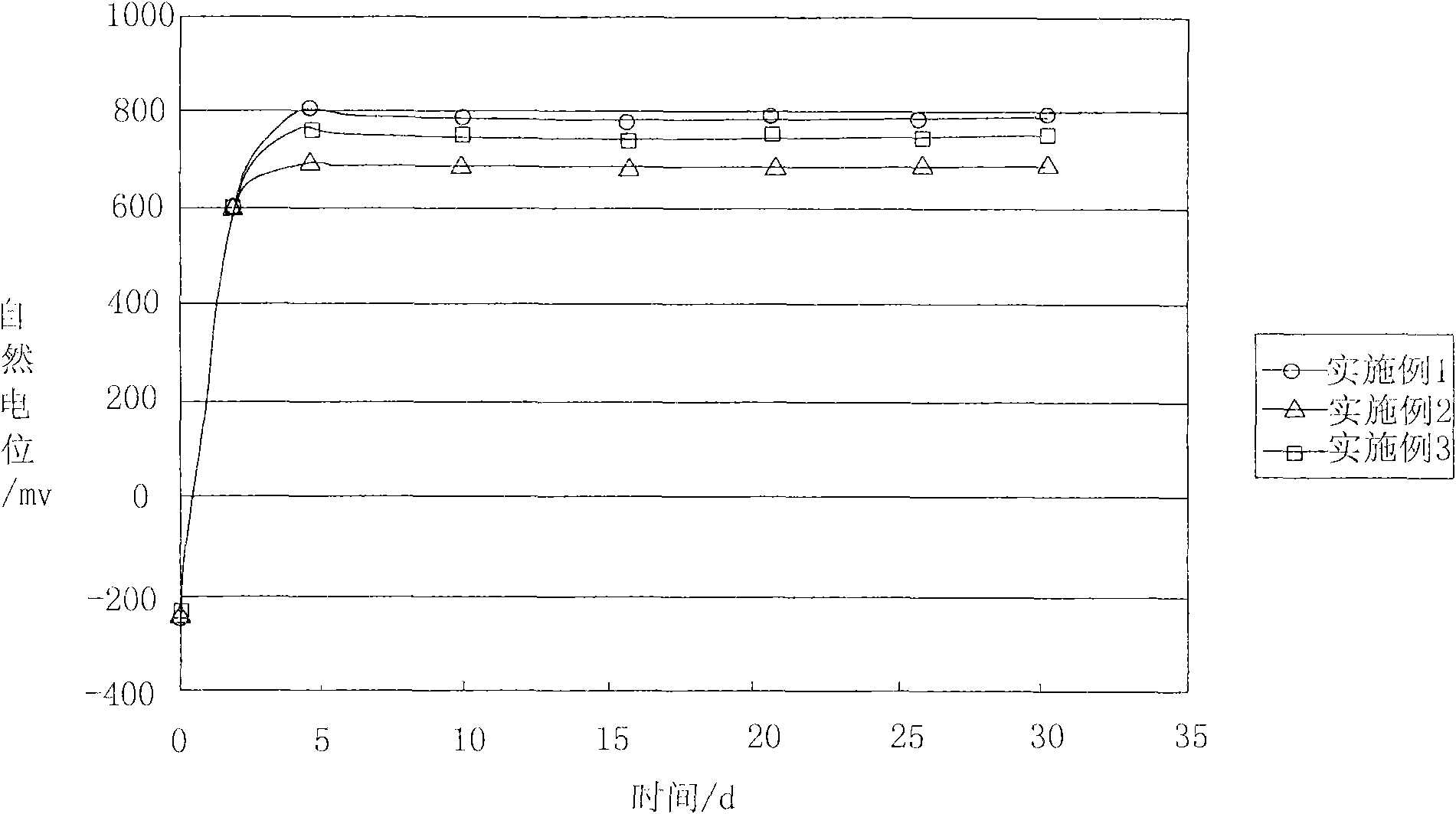

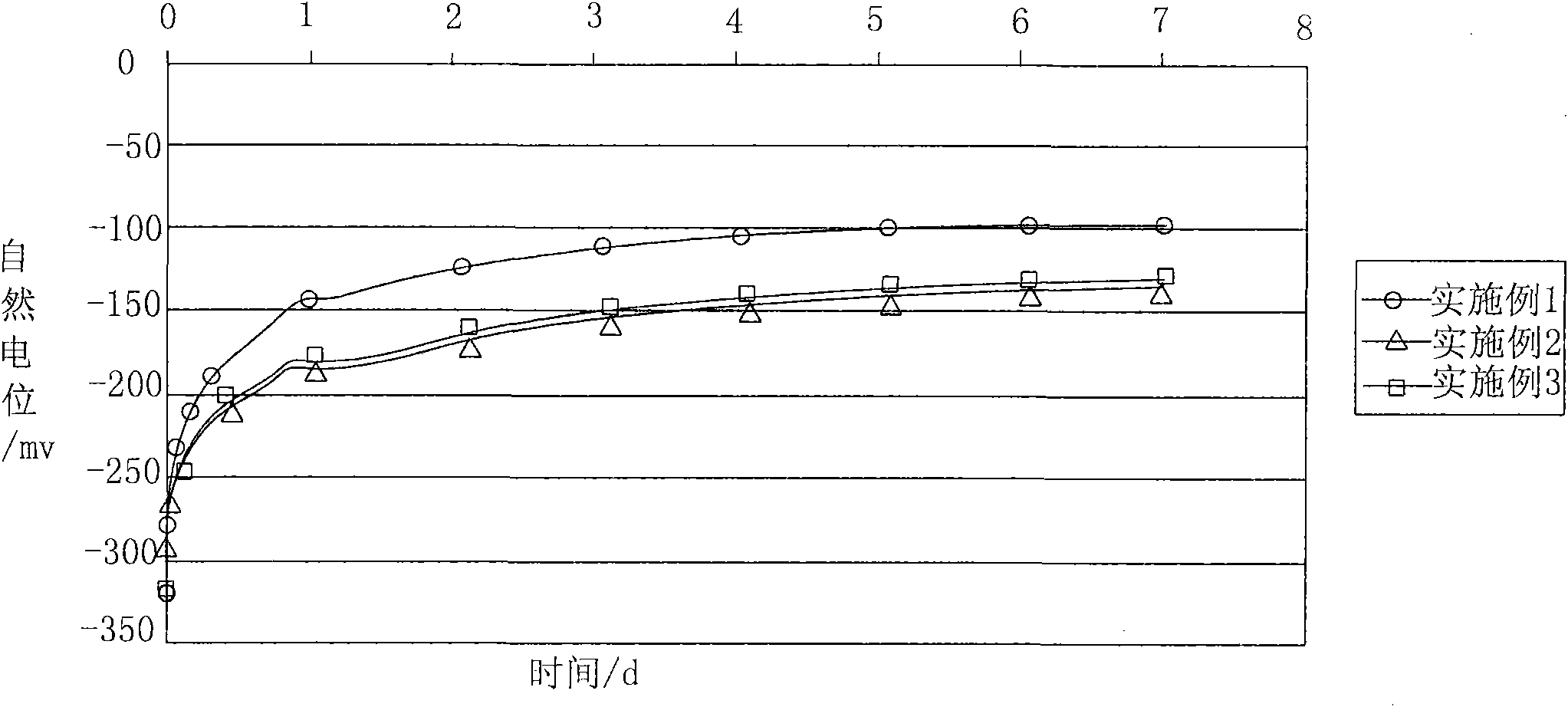

Embodiment 1

[0020] A composite reinforced concrete rust inhibitor, according to the weight percentage, the formula of the rust inhibitor is:

[0022] Sodium Hexametaphosphate 1.0%,

[0023] Sodium Benzoate 15.0%,

[0024] Air-entraining agent 0.03‰,

[0025] The rest is volcanic ash.

Embodiment 2

[0027] A composite reinforced concrete rust inhibitor, according to the weight percentage, the formula of the rust inhibitor is:

[0030] Sodium Benzoate 10.0%,

[0031] Air-entraining agent 0.03‰,

[0032] The rest is volcanic ash.

Embodiment 3

[0034] A composite reinforced concrete rust inhibitor, according to the weight percentage, the formula of the rust inhibitor is:

[0035] Calcium nitrite 30.0%,

[0036] Sodium Hexametaphosphate 1.0%,

[0038] Sodium Benzoate 10.0%,

[0039] Air-entraining agent 0.03‰,

[0040] The rest is volcanic ash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com