Microemulsion preparation taking rosin-based vegetable oil as solvent and preparation method thereof

A technology of turpentine-based vegetable oil and emulsion preparation, which is applied in the fields of botanical equipment and methods, plant growth regulators, animal repellents, etc. Odor, excellent spreading permeability, effect of improving stability over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

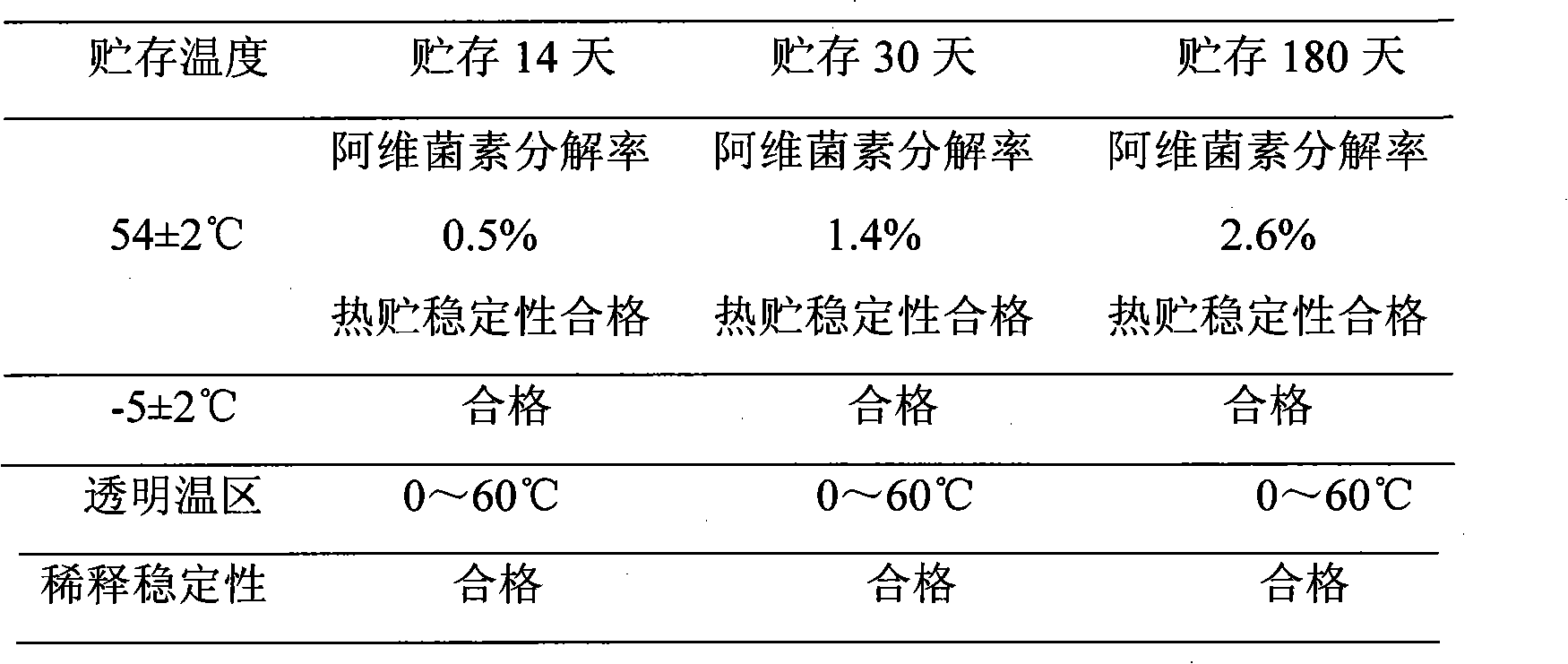

Embodiment 1

[0040] Weigh 18kg of avermectin, 100kg of rosin-based vegetable oil, 100kg of ethanol, 40kg of polyoxyethylene polyoxypropylene block copolymer, 30kg of C12-14 polyoxyethylene ether phosphate, and 30kg of linear calcium dodecylbenzenesulfonate 1 kg of methylpolysiloxane was added to the reactor, and it was sheared and dispersed evenly at 2000rpm / min; 681kg of deionized water was added, and it was sheared at a high speed of 5000rpm / min for 60min to form a 1000kg abamectin microemulsion preparation.

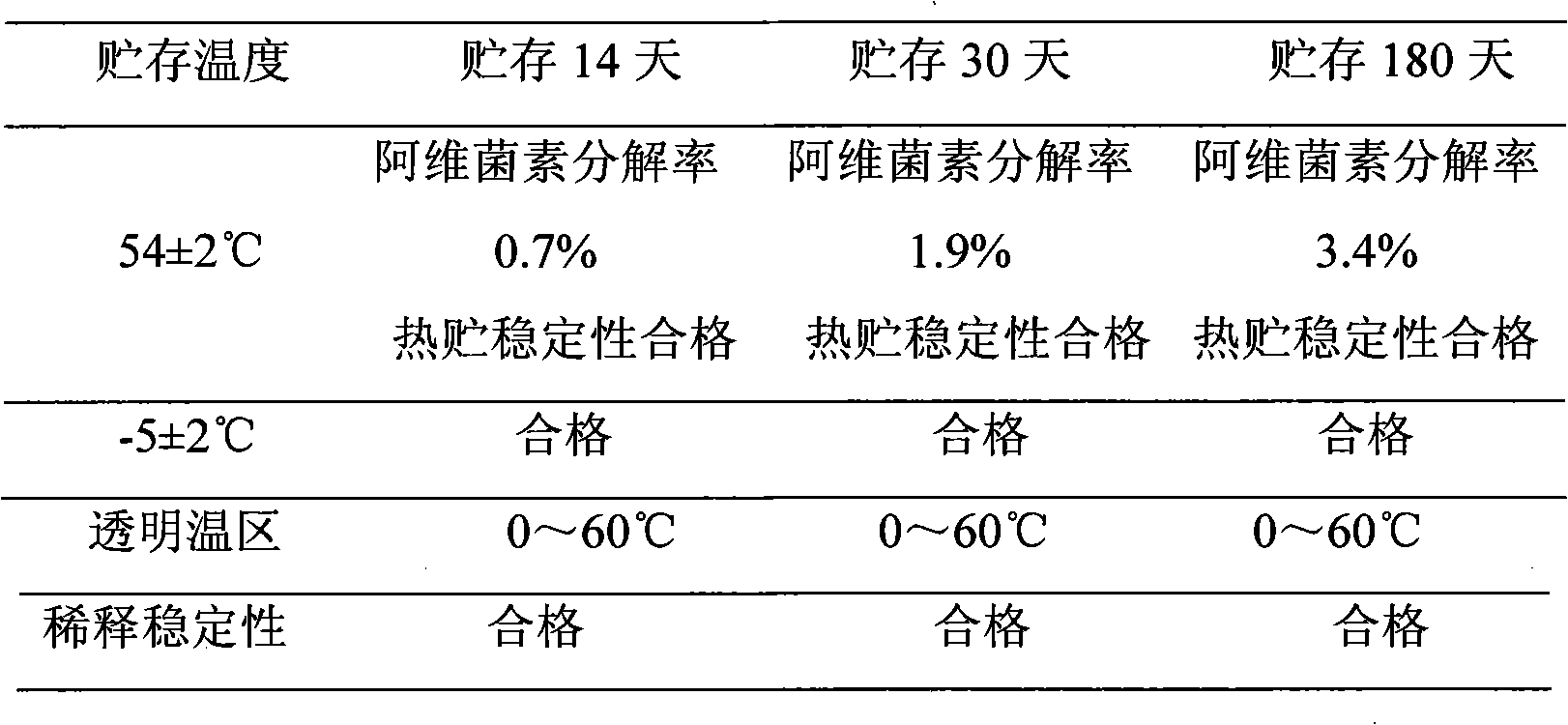

Embodiment 2

[0050] Weigh 50kg of avermectin, 150kg of rosin-based vegetable oil, 100kg of N-octylpyrrolidone, 50kg of polyoxyethylene polyoxypropylene block copolymer, 40kg of C12-14 polyoxyethylene ether phosphate, linear dodecylbenzene Add 40kg of calcium sulfonate and 1kg of methylpolysiloxane into the reactor, and shear and disperse evenly at 5000rpm / min; add 569kg of deionized water, and shear at 8000rpm / min for 20min to form 1000kg of abamectin microemulsion preparation.

Embodiment 3

[0052] Weigh 25kg of lambda-cyhalothrin, 60kg of turpentine-based vegetable oil, 20kg of ethylene glycol, 20kg of polyoxyethylene polyoxypropylene block copolymer, 20kg of fatty alcohol polyoxyethylene ether phosphate, linear dodecylbenzenesulfonate Add 25kg of acid amine and 1kg of methyl polysiloxane into the reaction kettle, and shear and disperse evenly at 3000rpm / min; add 829kg of deionized water, and shear at 5000rpm / min for 20min to form 1000kg of efficient cyhalothrin microemulsion preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com