Coenzyme Q10 clear preparation being added into skin caring articles and preparation method thereof

A skin care and coenzyme technology, applied in the field of coenzyme Q10 clarification preparation and its preparation, can solve problems such as water solubility and poor oil solubility, and achieve the effects of good fluidity, simple operation process and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] coenzyme Q 10 1g polyoxyethylene hydrogenated castor oil 2g

[0034] Polyethylene glycol caprylic acid / capric glyceride 1g Sodium carboxymethyl cellulose 0.3g

[0035] Deionized water 95.7g prepared with coenzyme Q 10 Clarified microemulsion 100g

[0036] Add the recipe amount Coenzyme Q 10 Stir slowly with polyoxyethylene hydrogenated castor oil and ethylene glycol caprylic acid / capric glyceride at 70 to form a uniform solution, add it to the aqueous solution containing carboxymethylcellulose sodium, and shear at 13000 rpm for 2 minutes ; put the material into the high-pressure homogenizer, and circulate 3 times at 150mpa to obtain coenzyme Q 10 Clarify the microemulsion solution, the pH value of the microemulsion solution is 6.6, and its particle size measured by laser particle size analyzer is 120nm.

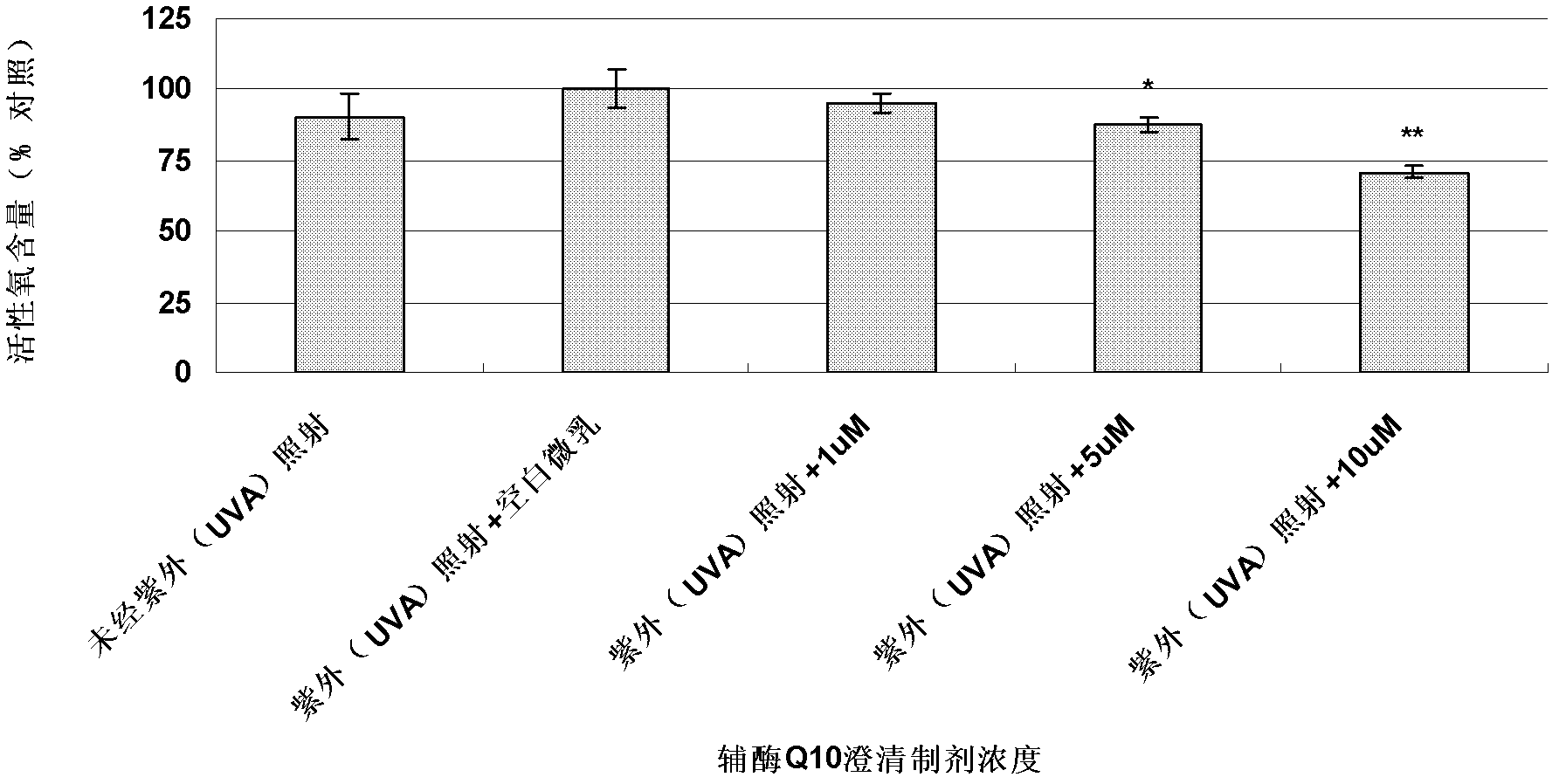

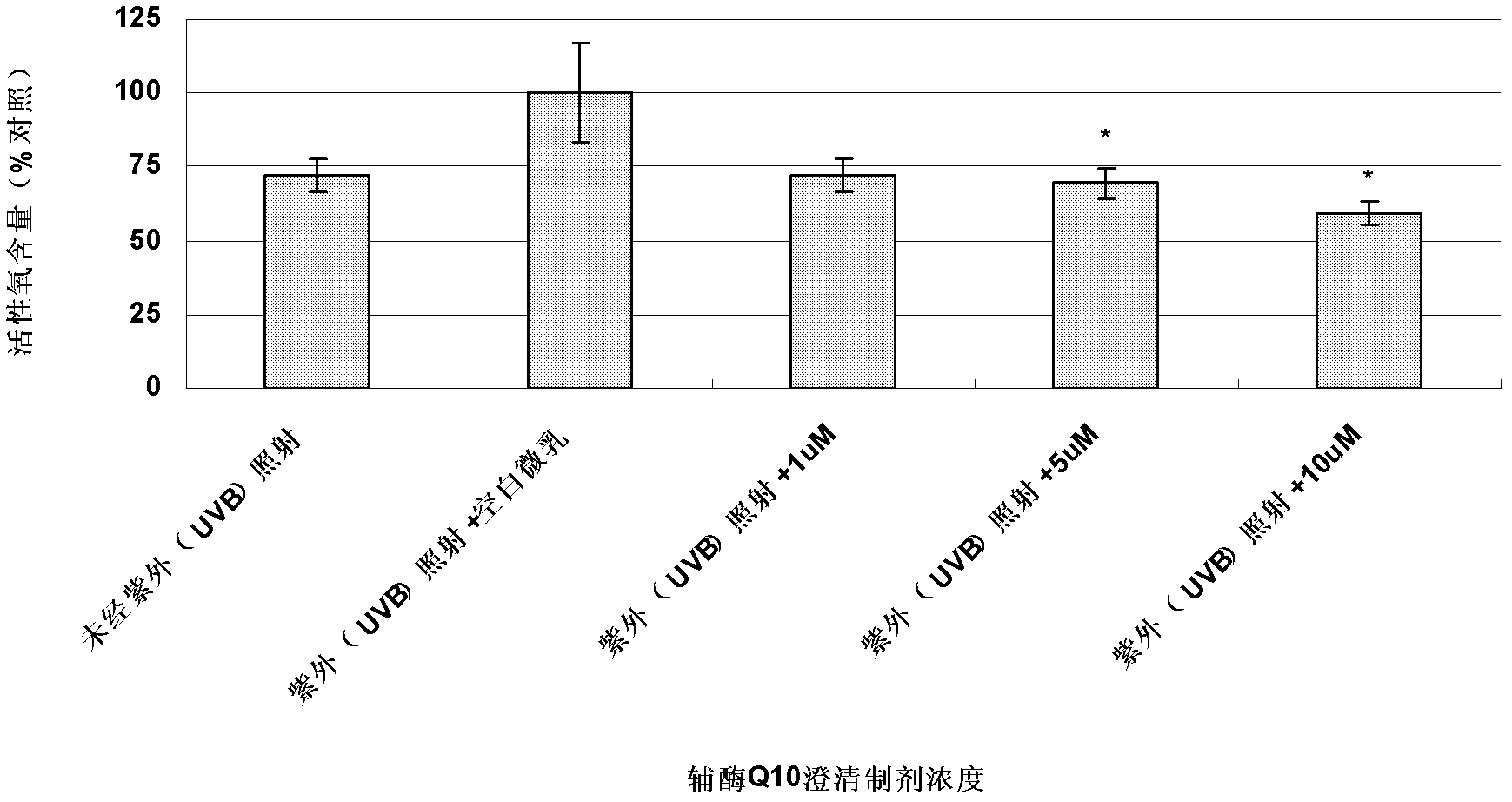

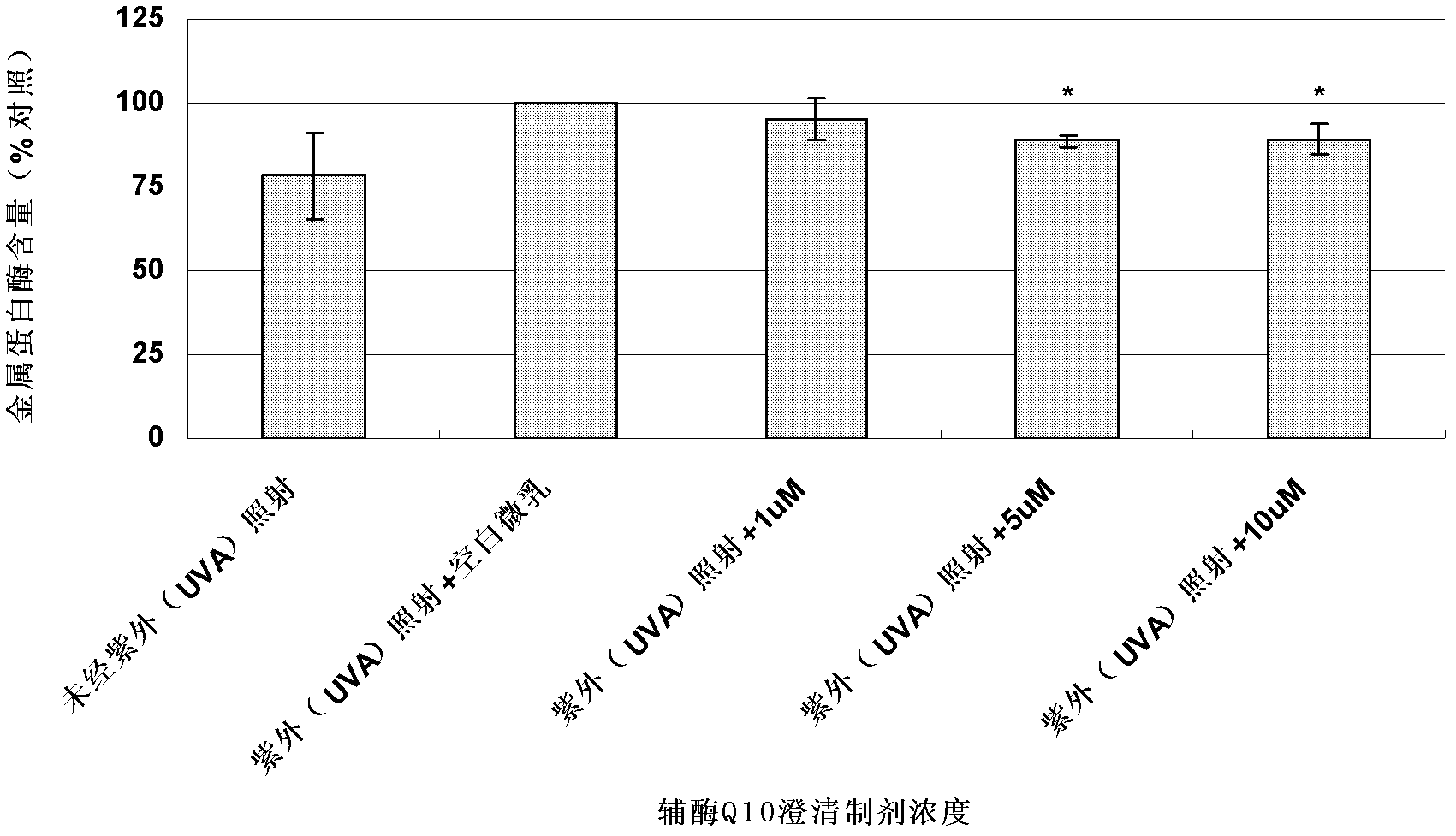

[0037] The results of skin cytology experiments show that this dosage form can reduce the metalloproteinase and active oxygen content in cells that are increased ...

Embodiment 2

[0039] coenzyme Q 10 5g Cetearyl Glucoside 2g

[0040] Polyethylene Glycol Cetyl Ether 10g Sodium Carboxymethyl Cellulose 5g

[0041] Deionized water 74.5g prepared with coenzyme Q 10 Clarified microemulsion 100g

[0042] Add the recipe amount Coenzyme Q 10 Stir slowly with oleyl polyether phosphate and polyethylene glycol ceteth to form a homogeneous solution, add it to the aqueous solution containing carboxymethylcellulose sodium, and shear at 15,000 rpm for 2 minutes; put Feed into high-pressure homogenizer, circulate 6 times with 150mpa, obtain coenzyme Q 10Clarify the microemulsion solution, the pH value of the microemulsion solution is 6.7, and its particle size is 100nm as measured by a laser particle size analyzer.

Embodiment 3

[0044] coenzyme Q 10 10g oleyl ether phosphate 5g

[0045] Polyethylene glycol ceteth 10g Acrylate 1g

[0046] Deionized water 74g prepared with coenzyme Q 10 Clarified microemulsion 100g

[0047] Add the recipe amount Coenzyme Q 10 Stir slowly with oleyl polyether phosphate and oleyl polyether phosphate to form a uniform solution, add it to the aqueous solution containing carboxymethyl cellulose sodium, and shear at 18000 rpm for 3 minutes at high speed; put the material into the high pressure The homogenizer circulates twice at 200mpa, and adjusts the pH value to 6.4 with 5% sodium hydroxide solution. get coenzyme Q 10 The clarified microemulsion solution has a particle size of 105nm as measured by a laser particle size analyzer.

[0048] After the dosage form is placed at normal temperature (25° C.), it remains stable and transparent, and there is no stratification after 6 months. It can be placed stably for 3 months after accelerated test at 45°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com