Preparation method of nannochloropsis oculata polysaccharide with antioxidant activity

A technology of antioxidant activity and Nannochloropsis, which is applied in fermentation and other directions, can solve the problems of high-efficiency extraction and purification of seaweed polysaccharides, and achieve the effect of improving biological activity and extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

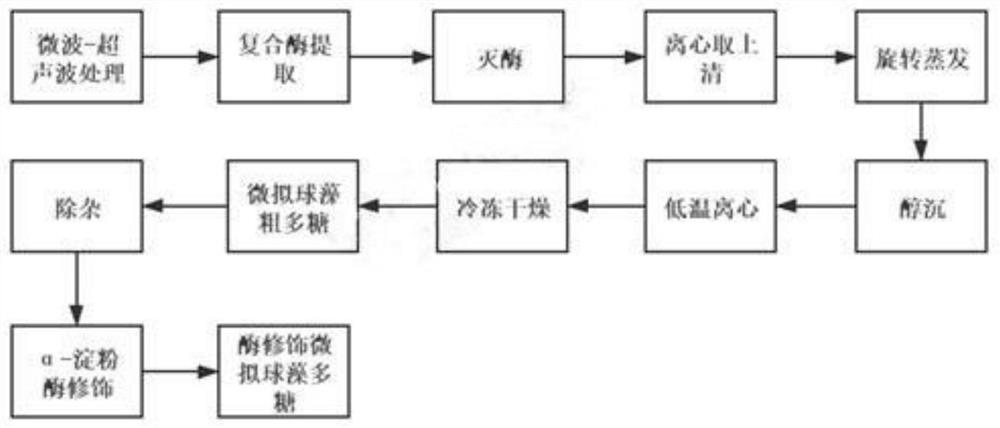

[0046] The preparation method of the Nannochloropsis polysaccharide with antioxidant activity of the present invention specifically comprises the following steps:

[0047] (1) Weigh 10 g of Nannochloropsis algae powder and add 100 mL of distilled water, place it in an extractor, and perform ultrasonic-microwave treatment for 20 minutes under the conditions of 350W ultrasonic power and 150W microwave power to obtain an extract;

[0048] (2) Add 0.3% compound enzyme to the extract under the condition of 50°C, the compound enzyme is cellulase and pectinase, cellulase: pectinase = 1:1, enzymolysis for 2 hours, to obtain liquid;

[0049] (3) The enzymatic hydrolysis solution was inactivated in a water bath at 80°C for 30 minutes, cooled and placed in a high-speed refrigerated centrifuge at 5000r / min, centrifuged at 4°C for 15 minutes, and the supernatant was taken;

[0050] (4) After the supernatant is distilled under reduced pressure, carry out alcohol precipitation with absolute...

Embodiment 2

[0065] (1) Weigh 10 g of Nannochloropsis algae powder and add 100 mL of distilled water, place it in an extractor, and perform ultrasonic-microwave treatment for 15 minutes under the conditions of 300 W ultrasonic power and 100 W microwave power to obtain an extract;

[0066] (2) Add 0.2% compound enzyme to the extract at 50°C, the compound enzyme is cellulase and pectinase, cellulase: pectinase = 1:1, enzymatic hydrolysis for 2 hours, to obtain liquid;

[0067] (3) The enzymatic hydrolysis solution was inactivated in a water bath at 80°C for 30 minutes, cooled and placed in a high-speed refrigerated centrifuge at 5000r / min, centrifuged at 4°C for 15 minutes, and the supernatant was taken;

[0068] (4) After the supernatant is distilled under reduced pressure, carry out alcohol precipitation with absolute ethanol 3 times the volume of the remaining solution, and let it stand for 10 minutes;

[0069] (5) Place the mixed solution after alcohol precipitation in a centrifuge at 5...

Embodiment 3

[0074] (1) Weigh 10 g of Nannochloropsis algae powder and add 100 mL of distilled water, place it in an extractor, and perform ultrasonic-microwave treatment for 25 minutes under the conditions of 400W ultrasonic power and 200W microwave power to obtain an extract;

[0075] (2) Add 1% compound enzyme to the extract under the condition of 50°C, the compound enzyme is cellulase and pectinase, cellulase: pectinase=1:1, enzymolysis for 2 hours, to obtain liquid;

[0076] (3) The enzymatic hydrolysis solution was inactivated in a water bath at 80°C for 30 minutes, cooled and placed in a high-speed refrigerated centrifuge at 5000r / min, centrifuged at 4°C for 15 minutes, and the supernatant was taken;

[0077] (4) After the supernatant is distilled under reduced pressure, carry out alcohol precipitation with absolute ethanol 3 times the volume of the remaining solution, and let it stand for 10 minutes;

[0078] (5) Place the mixed solution after alcohol precipitation in a centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com