Flash memory and manufacturing method thereof

A memory and flash technology, applied in the field of non-volatile semiconductor memory, can solve the problems of leakage current, affect the use range of flash memory, small channel current, etc., achieve low power consumption, suppress source-drain punch-through effect, and solve work problems. low current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

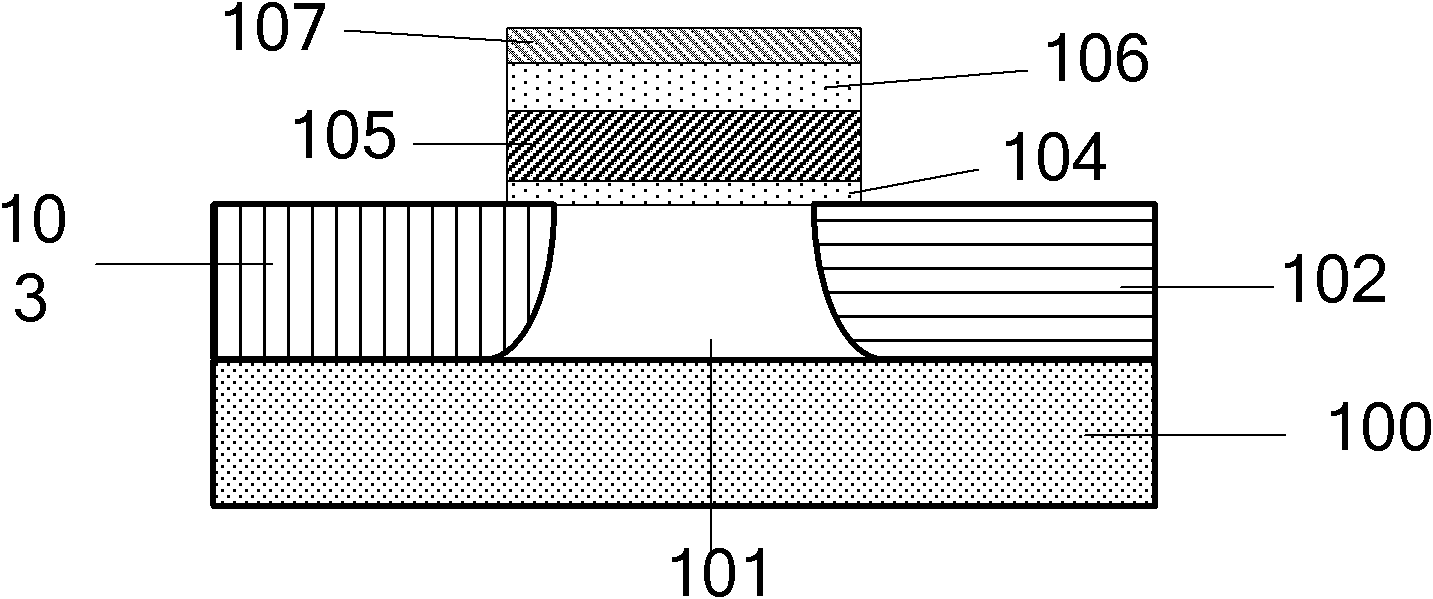

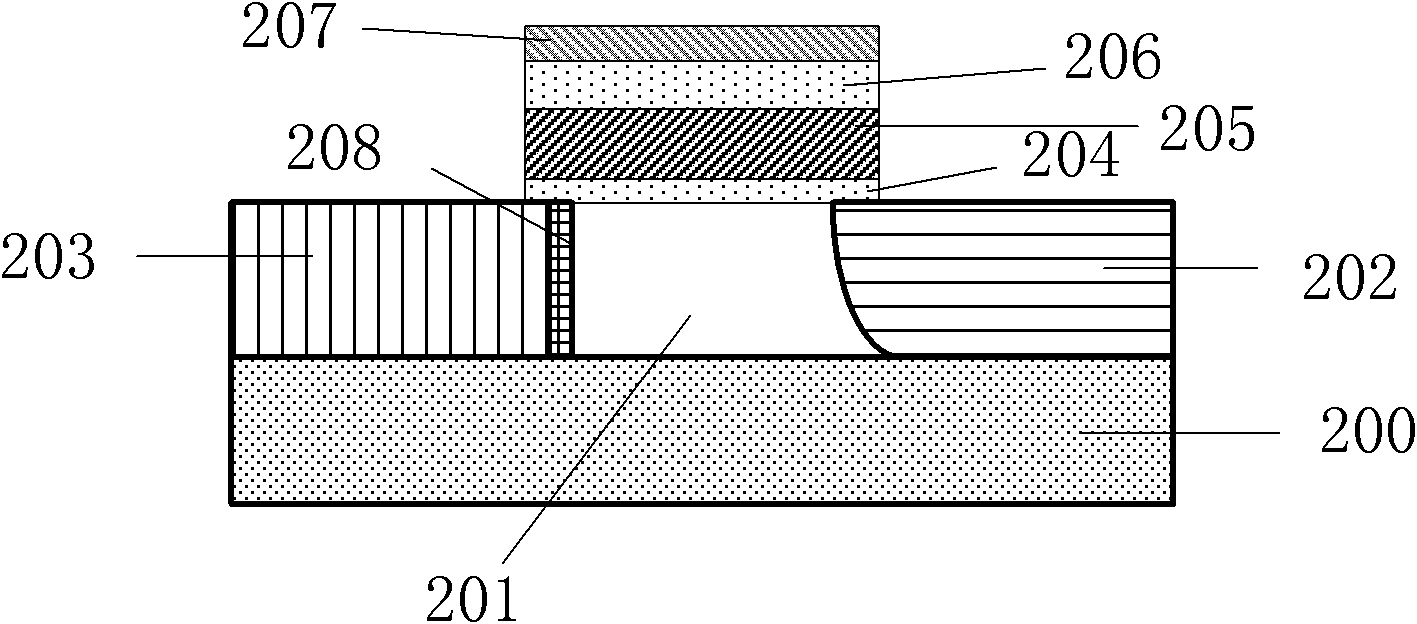

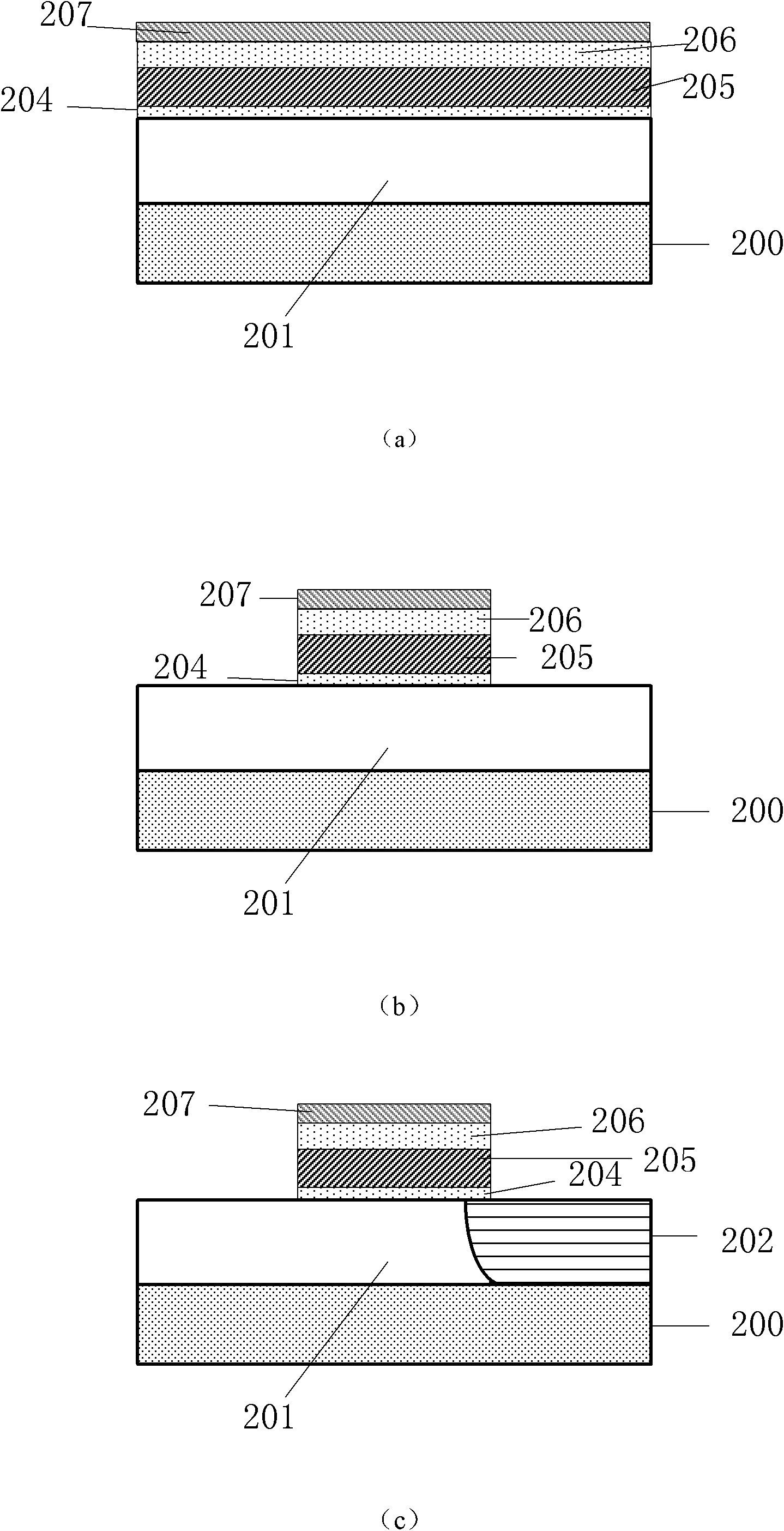

[0037] Below in conjunction with accompanying drawing, further illustrate the preparation of flash memory of the present invention

[0038] The preparation of above-mentioned flash memory comprises the following steps:

[0039] 1) Single throw SOI silicon substrate, shallow trench isolation (STI);

[0040] 2) A sacrificial oxide layer is thermally grown to improve the surface quality of the channel, and the sacrificial oxide layer is rinsed off with hydrofluoric acid. Then thermally grow an oxide layer of 8 nanometers 204 (tunneling oxide layer), and then deposit a polysilicon layer of 90 nanometers, and heavily dope the polysilicon layer to form a floating gate structure 205;

[0041] 3) Deposit oxide layer 10 nanometers 206 (barrier oxide layer) and polysilicon 50 nanometers polysilicon afterwards, form as image 3 (a) structure;

[0042] 4) heavily doping the top polysilicon, followed by rapid thermal annealing (RTA) to activate the impurities in the control gate 207 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com