Granular sludge sewage treatment device capable of controlling diameter and density of granules

A sewage treatment device and technology of granular sludge, applied in the direction of aerobic and anaerobic process treatment, can solve the problem of no biological treatment process, and achieve good effluent quality, good simultaneous nitrification and denitrification, and good effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

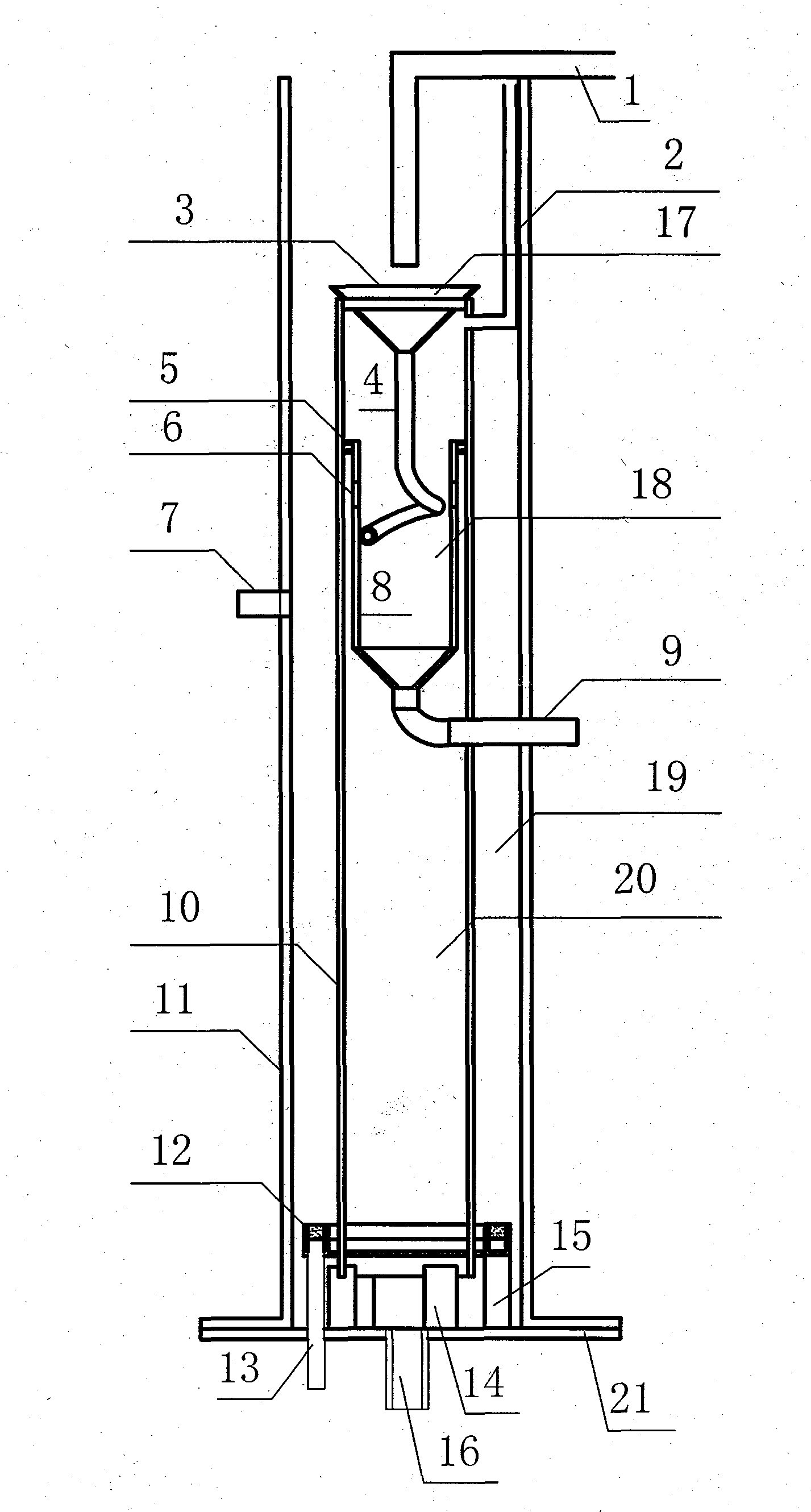

[0023] As shown in the accompanying drawings, the present invention is a granular sludge sewage treatment device that can control particle size and density, including a concentric inner cylinder 10 and an outer cylinder 11, the lower edge of the inner cylinder 10 is higher than the lower edge of the outer cylinder 11 The upper edge of the inner cylinder 10 is lower than the upper edge of the outer cylinder 11. The outer cylinder 11 is fixed upright on the base 21. There is a water outlet 7 on the side wall of the outer cylinder 11. The inner cylinder 10 is fixed by the inner cylinder support pile 14. On the base 21, an aeration device 12 is arranged in the annular space between the inner cylinder 10 and the outer cylinder 11, the aeration device 12 is fixed on the base 21 through the aeration device support pile 15, and the aeration device 12 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com