Extracting method for toosendanin

An extraction method and technology for azadirachtin, applied in the directions of steroids, organic chemistry, etc., can solve the problems of effective chemical activity destruction of azadirachtin, many impurities, low yield, etc., and achieve high efficiency absorption, high extraction rate, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

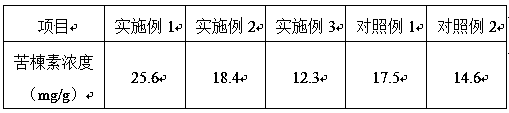

Examples

Embodiment 1

[0029] Wash and dry the neem bark, crush it to 100-200 mesh, add water and mix, the mass ratio of neem powder and water is 1:50; after fully mixing, add cellulase and pectinase, cellulase and pectin The mass ratio of enzyme and neem powder is 1:1:20, adjust the mixed system to adjust the pH value to 3.5-5.5, the temperature is 40-50°C, and fully react for 2 hours in an ultrasonic field with an ultrasonic power of 200W and an ultrasonic frequency of 20KHz , Filtrate 1 and filter residue 1 were obtained by filtration.

[0030] Add the filter residue 1 to the disodium hydrogen phosphate-phosphate buffer solution with a pH value of 2.2, mix evenly at room temperature, fully extract the filtrate 2 and filter residue 2 in an ultrasonic field with an ultrasonic power of 200W and an ultrasonic frequency of 20KHz for 2 hours The filter residue 2 is added to the phthalic acid-sodium hydroxide buffer solution with a pH value of 5.5, mixed uniformly at room temperature, and the filtered f...

Embodiment 2

[0033] Wash and dry the neem seeds, crush them to 100-200 mesh, add water and mix, the mass ratio of neem powder and water is 1:80; after mixing well, add cellulase and pectinase, cellulase and pectin The mass ratio of enzyme and neem powder is 1:1:15, adjust the mixed system to adjust the pH value to 3.5-5.5, the temperature is 40-50°C, and fully react for 2 hours in an ultrasonic field with an ultrasonic power of 200W and an ultrasonic frequency of 20KHz , Filtrate 1 and filter residue 1 were obtained by filtration.

[0034] Add the filter residue 1 to the acetic acid-sodium acetate buffer solution with a pH value of 2.6, mix evenly at room temperature, fully extract the filtered filtrate 2 and filter residue 2 in an ultrasonic field with an ultrasonic power of 200W and an ultrasonic frequency of 20KHz for 2 hours; The filter residue 2 was added to the disodium hydrogen phosphate-potassium dihydrogen phosphate buffer solution with a pH value of 6.0, mixed uniformly at room t...

Embodiment 3

[0037] Wash and dry the neem bark, crush it to 100-200 mesh, add water and mix, the mass ratio of neem powder and water is 1:100; after fully mixing, add cellulase and pectinase, cellulase and pectin The mass ratio of enzyme and neem powder is 1:1:10, adjust the mixed system to adjust the pH value to 3.5-5.5, the temperature is 40-50°C, and fully react for 2 hours in an ultrasonic field with an ultrasonic power of 200W and an ultrasonic frequency of 20KHz , Filtrate 1 and filter residue 1 were obtained by filtration.

[0038]Add the filter residue 1 to the acetic acid-ammonium acetate buffer solution with a pH value of 3.0, mix evenly at room temperature, fully extract the filtered filtrate 2 and filter residue 2 in an ultrasonic field with an ultrasonic power of 200W and an ultrasonic frequency of 20KHz for 2 hours; The filter residue 2 was added to the disodium hydrogen phosphate-potassium dihydrogen phosphate buffer solution with a pH value of 6.5, mixed uniformly at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com