Optical diffusion membrane

A technology of optical diffusion and main diffusion, applied in the field of optical diffuser film, can solve the problems of scratches, pollution, and detachment of diffusing agent microbeads on the optical diffuser film, and achieve good antistatic properties, good scratch resistance, and sufficient optical diffusion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

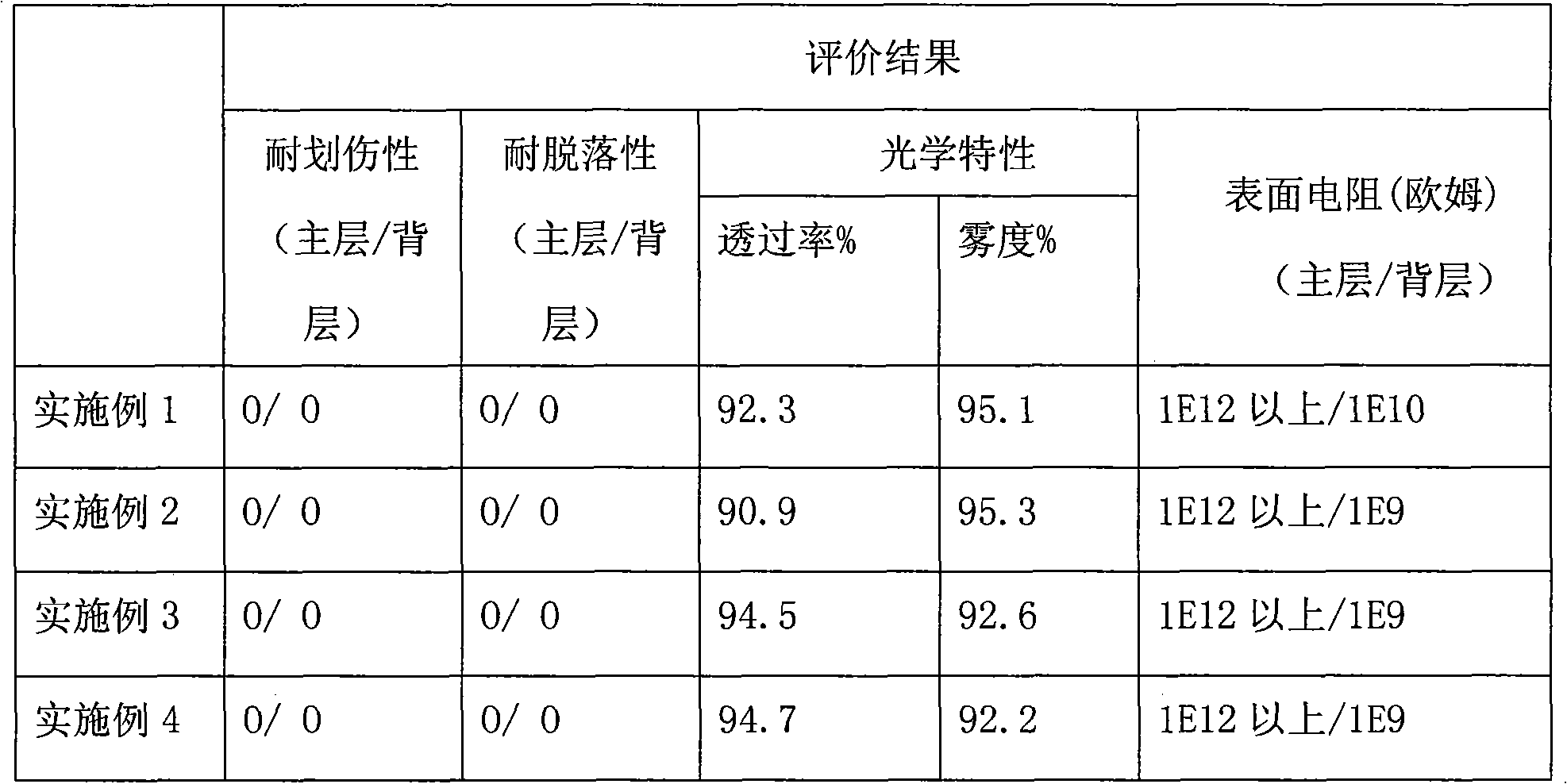

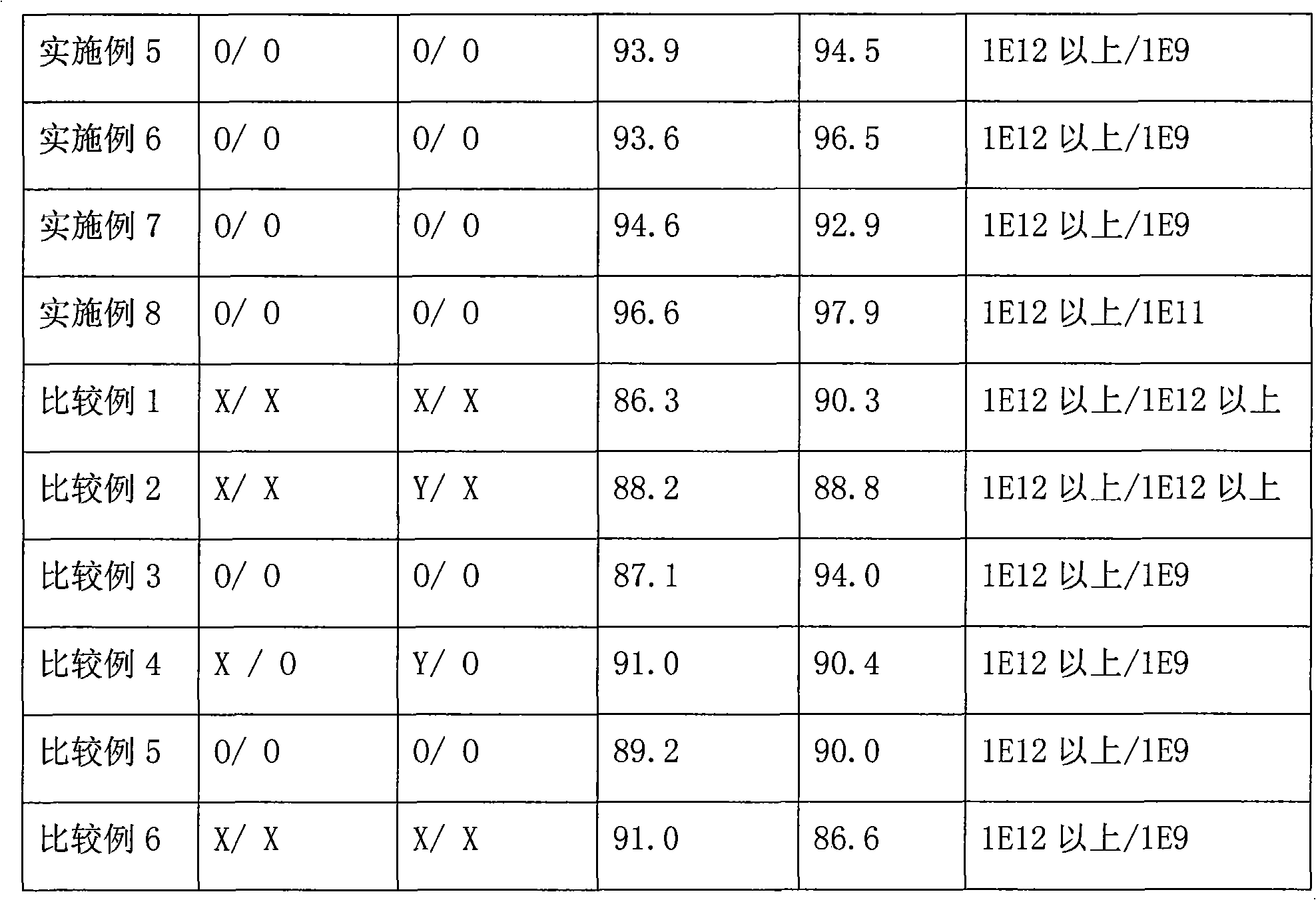

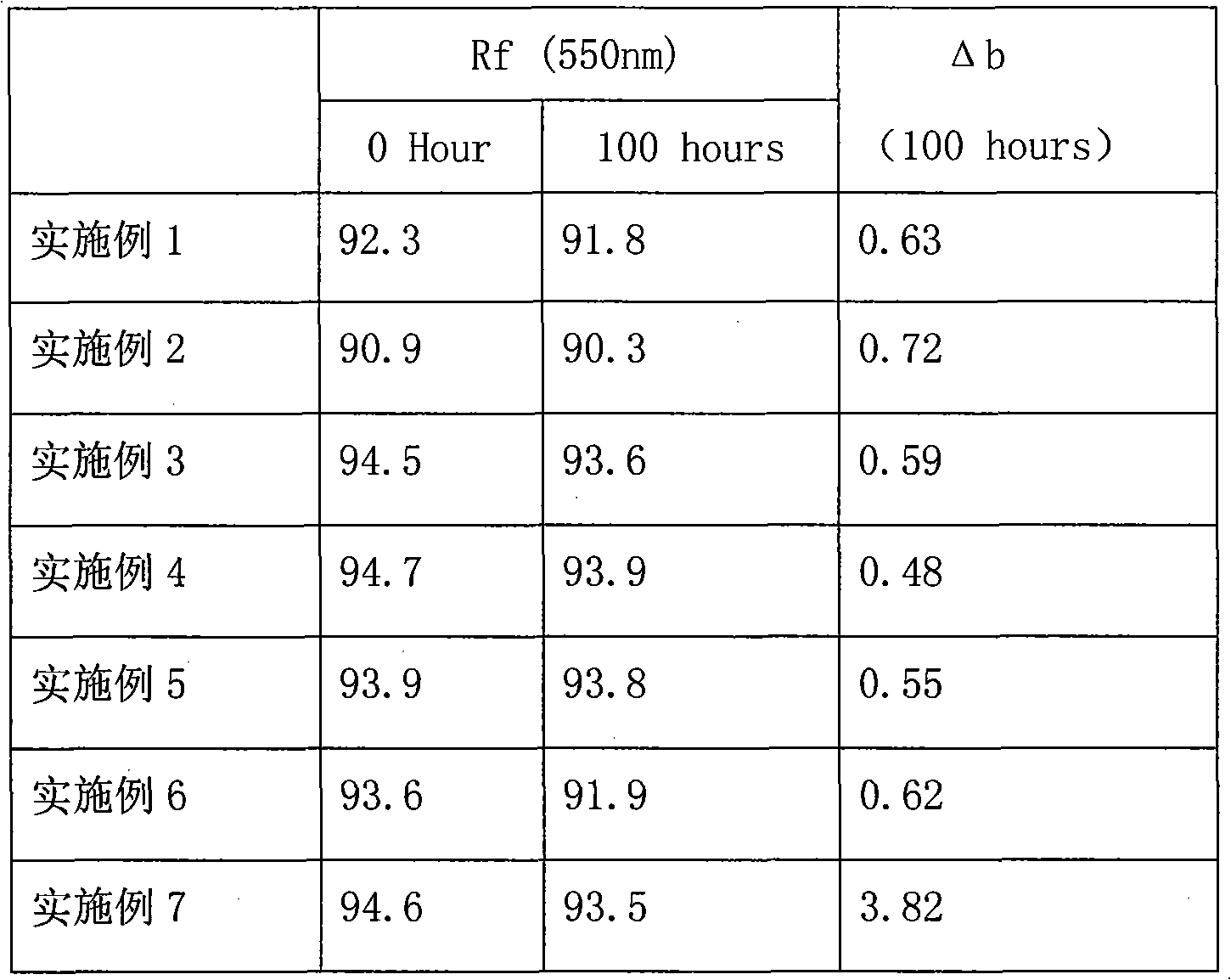

Examples

Embodiment 1

[0031] Preparation of main diffusion layer coating solution:

[0032] 200 parts of toluene, 50 parts of butanone,

[0033] Acrylic resin microbeads (GM-1407S, product of Kangci Chemical Co., Ltd., particle size 14 microns) 150 parts,

[0034] Acrylic resin microbeads (GM-0407S, product of Kangci Chemical Co., Ltd., particle size 4 microns) 15 parts,

[0035] Polyacrylate resin binder (WDU-938, 50% solid content, 50 hydroxyl value, DIC company product) 100 parts,

[0036] 7 parts of isocyanate crosslinking agent IPDI (Desmodur I, NCO content 37%, product of Bayer Company),

[0037] The above-mentioned materials were stirred and mixed with a dispersing mixer to obtain a coating solution for the main diffusion layer.

[0038] Preparation of back diffusion layer coating solution:

[0039] 150 parts of toluene, 150 parts of butanone,

[0040] Acrylic resin micro-beads (GM-0407S, product of Kangci Chemical Co., Ltd., particle size 4 microns) 5 parts,

[0041] Acrylic adhesive (W...

Embodiment 2

[0047] Preparation of main diffusion layer coating solution:

[0048] 200 parts of toluene, 50 parts of butanone,

[0049] Acrylic resin microbeads (GM-2007S, product of Kangci Chemical Co., Ltd., particle size 20 microns) 150 parts,

[0050] Acrylic resin microbeads (GM-0407S, product of Kangci Chemical Co., Ltd., particle size 4 microns) 20 parts,

[0051] Acrylic adhesive (WDU-938, solid content 50%, hydroxyl value 50, DIC company product) 100 parts,

[0052] 7 parts of isocyanate crosslinking agent IPDI (Desmodur I, NCO content 37%, product of Bayer Company),

[0053] The above-mentioned materials were stirred and mixed with a dispersing mixer to obtain a coating solution for the main diffusion layer.

[0054] Preparation of back diffusion layer coating solution:

[0055] 150 parts of toluene, 150 parts of butanone,

[0056] Acrylic resin micro-beads (GM-0407S, product of Kangci Chemical Co., Ltd., particle size 4 microns) 5 parts,

[0057] Acrylic adhesive (WDU-938,...

Embodiment 3

[0063] Use the main diffusion layer coating solution A and the substrate in the above-mentioned Example 1 to coat, dry with hot air to make the dry film thickness about 9 μm, and then apply the back diffusion layer coating in Example 2 on the other side of the substrate. Spread liquid b and dry with hot air to make the dry film thickness about 2 μm. After the coating was completed, thermal aging treatment was carried out at a constant temperature of 40° C. for 48 hours to form an optical diffusion film, and its performance was measured (see Table 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com