Optical diffusion film and preparation method thereof

An optical diffusion and optical substrate technology, applied in the field of optical diffusion film and its preparation, to achieve the effects of good transparency and scratch resistance, good coordination between transmittance and haze, and good coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

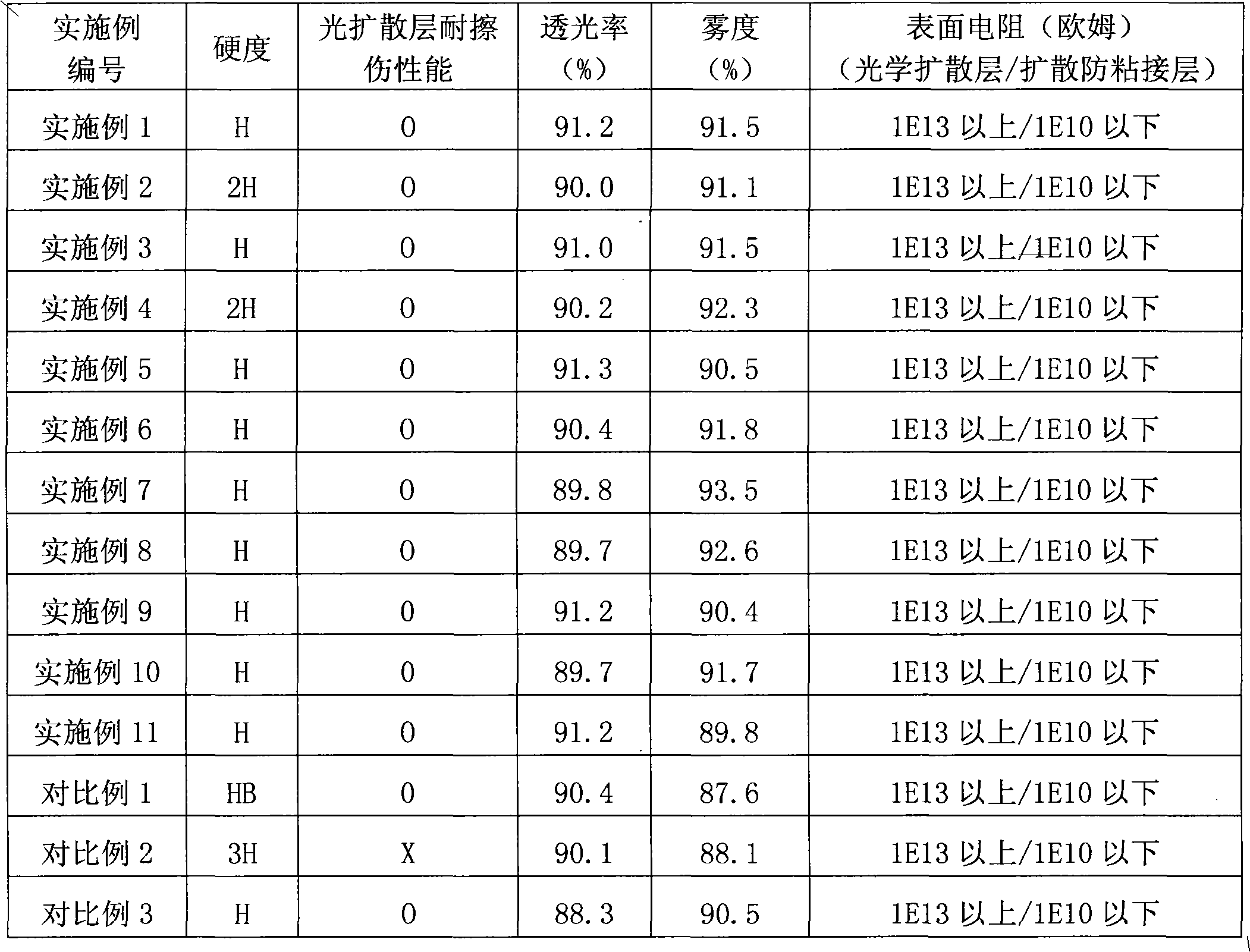

Examples

Embodiment 1

[0043] Preparation of optical diffusion layer coating solution:

[0044] Butanone 25 parts by mass

[0045] 25 parts by mass of toluene

[0046] 5 parts by mass of propylene glycol monomethyl ether

[0047] Polymethyl methacrylate microbeads (MBX-40, product of Sekisui Chemical Co., Ltd., average particle size 40 μm) 2 parts by mass

[0048] Polymethyl methacrylate microbeads (MBX-15, product of Sekisui Chemical Co., Ltd., average particle diameter of 15 μm) 8 parts by mass

[0049] Polymethyl methacrylate microbeads (MB20X-5, product of Sekisui Chemical Co., Ltd., particle average particle size 5 μm) 10 parts by mass

[0050] Polyacrylate polyol (WDU-938, DIC company product, solid content 50%, hydroxyl value 50mgKOH / g) 18 mass parts

[0051] Polyester polyol (PD110LV, Stepan company, hydroxyl value 115mgKOH / g) 2 parts by mass

[0052] HDI trimer (N3600, Bayer product, NCO content 23%) 4 parts by mass

[0053] Modified polysiloxane dispersant (Disponer 931, Elementis Sp...

Embodiment 2

[0067] Preparation of optical diffusion layer coating solution:

[0068] Butanone 20 parts by mass

[0069] 15 parts by mass of ethyl acetate

[0070] 5 parts by mass of propylene glycol butyl ether

[0071] Polymethyl methacrylate microbeads (MBX-30, product of Sekisui Chemical Co., Ltd., average particle diameter of 30 μm) 2 parts by mass

[0072] Polymethyl methacrylate microbeads (MBX-15, product of Sekisui Chemical Co., Ltd., average particle diameter of 15 μm) 20 parts by mass

[0073] Polymethyl methacrylate microbeads (MB20X-5, product of Sekisui Chemical Co., Ltd., particle average particle size 5 μm) 13 parts by mass

[0074] Polyacrylate polyol (WDU-938, DIC company product, solid content 50%, hydroxyl value 50mgKOH / g) 15 mass parts

[0075] Polyester polyol (PD110LV, Stepan company, hydroxyl value 115mgKOH / g) 5 parts by mass

[0076] HDI biuret (N100, Bayer product, 100% solid content, 22% NCO content) 4 parts by mass

[0077] Carboxyl-containing polyester di...

Embodiment 3

[0091] Preparation of optical diffusion layer coating solution:

[0092] 10 parts by mass of acetone

[0093] 30 parts by mass of toluene

[0094] 10 parts by mass of propylene glycol monomethyl ether

[0095] Polymethyl methacrylate microbeads (MBX-20, product of Sekisui Chemical Co., Ltd., particle average particle size 20 μm) 10 parts by mass

[0096] Polymethyl methacrylate microbeads (MBX-10, product of Sekisui Chemical Co., Ltd., average particle diameter of 10 μm) 5 parts by mass

[0097] Polymethyl methacrylate microbeads (MB20X-8, product of Sekisui Chemical Co., Ltd., average particle size 8 μm) 5 parts by mass

[0098] Polyacrylate polyol (WDU-938, DIC company product, solid content 50%, hydroxyl value 50mgKOH / g) 10 mass parts

[0099] Polyester polyol (RD181X, Bayer product, solid content 75%, hydroxyl value 122mgKOH / g) 5 parts by mass

[0100] HDI trimer (N3600, Bayer product, 100% solid content, 23% NCO content) 2 parts by mass

[0101] Modified polysiloxan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com