Scratch-proof optics diffusion film and preparation method thereof

An optical diffusion, anti-scratch technology, applied in optics, optical components, coatings, etc., can solve the problem of thin optical diffusion film being easily scratched, and achieve good transmittance and haze coordination, full optical diffusion The effect of improving the coordination of transmittance and haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

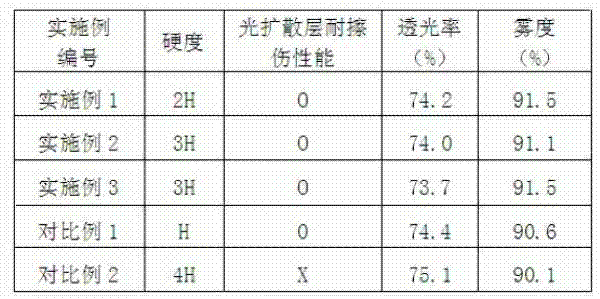

Examples

Embodiment 1

[0038] Preparation of optical diffusion layer coating solution:

[0039] Butanone 25 parts by mass

[0040] 25 parts by mass of toluene

[0041] 5 parts by mass of propylene glycol monomethyl ether

[0042] Polymethyl methacrylate microbeads (MBX-30, product of Sekisui Chemical Co., Ltd., average particle diameter of 30 μm) 2 parts by mass

[0043] Polymethyl methacrylate microbeads (MBX-10, product of Sekisui Chemical Co., Ltd., average particle size of 10 μm) 10 parts by mass

[0044] Polymethyl methacrylate microbeads (MB20X-8, product of Sekisui Chemical Co., Ltd., average particle size 8 μm) 8 parts by mass

[0045] Polyacrylate polyol (WDU-938, product of DIC company, solid content 50%, hydroxyl value 50mgKOH / g) 15 parts by mass

[0046] Polyurethane acrylate (product of Sartomer, USA, brand name CN9006) 5 parts by mass

[0047] 1 part by mass of dipentaerythritol hexaacrylate DPHA

[0048] HDI trimer (N3600, product of Bayer, NCO content 23%) 3 parts by mass

[0...

Embodiment 2

[0064] Preparation of Optical Diffusion Layer Coating Solution :

[0065] Butanone 25 parts by mass

[0066] 25 parts by mass of toluene

[0067] 5 parts by mass of propylene glycol monomethyl ether

[0068] Polymethyl methacrylate microbeads (MBX-30, product of Sekisui Chemical Co., Ltd., average particle diameter of 30 μm) 2 parts by mass

[0069] Polymethyl methacrylate microbeads (MBX-10, product of Sekisui Chemical Co., Ltd., average particle size of 10 μm) 8 parts by mass

[0070] Polymethyl methacrylate microbeads (MB20X-8, product of Sekisui Chemical Co., Ltd., average particle size 8 μm) 10 parts by mass

[0071] Polyacrylate polyol (WDU-938, DIC company product, solid content 50%, hydroxyl value 50mgKOH / g) 10 parts by mass

[0072] Urethane acrylate (product of Sartomer, USA, brand name CN9006) 8.4 parts by mass

[0073] 3.6 parts by mass of dipentaerythritol hexaacrylate DPHA

[0074] HDI trimer (N3600, Bayer product, NCO content 23%) 2 parts by mass

[0075] ...

Embodiment 3

[0082] Preparation of optical diffusion layer coating solution:

[0083] Butanone 25 parts by mass

[0084] 25 parts by mass of toluene

[0085] 5 parts by mass of propylene glycol monomethyl ether

[0086] Polymethyl methacrylate microbeads (MBX-30, product of Sekisui Chemical Co., Ltd., average particle size 30 μm) 4 parts by mass

[0087] Polymethyl methacrylate microbeads (MBX-10, product of Sekisui Chemical Co., Ltd., average particle size of 10 μm) 8 parts by mass

[0088] Polymethyl methacrylate microbeads (MB20X-8, product of Sekisui Chemical Co., Ltd., average particle size 8 μm) 8 parts by mass

[0089] Polyacrylate polyol (WDU-938, DIC company product, solid content 50%, hydroxyl value 50mgKOH / g) 6 parts by mass

[0090] Polyurethane acrylate (product of Sartomer, USA, brand name CN9006) 12 parts by mass

[0091] 4.8 parts by mass of dipentaerythritol hexaacrylate DPHA

[0092] HDI trimer (N3600, product of Bayer, NCO content 23%) 1.2 parts by mass

[0093] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com