Efficient control method of hardness of one-sided surface compressed wood

A control method and technology of compressing wood, which is applied in the direction of wood compression, etc., can solve the problems of large difference in performance of single-sided compressed wood, waste of wood, energy loss, etc., and achieve the goals of saving wood volume, improving production efficiency, and reducing production energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

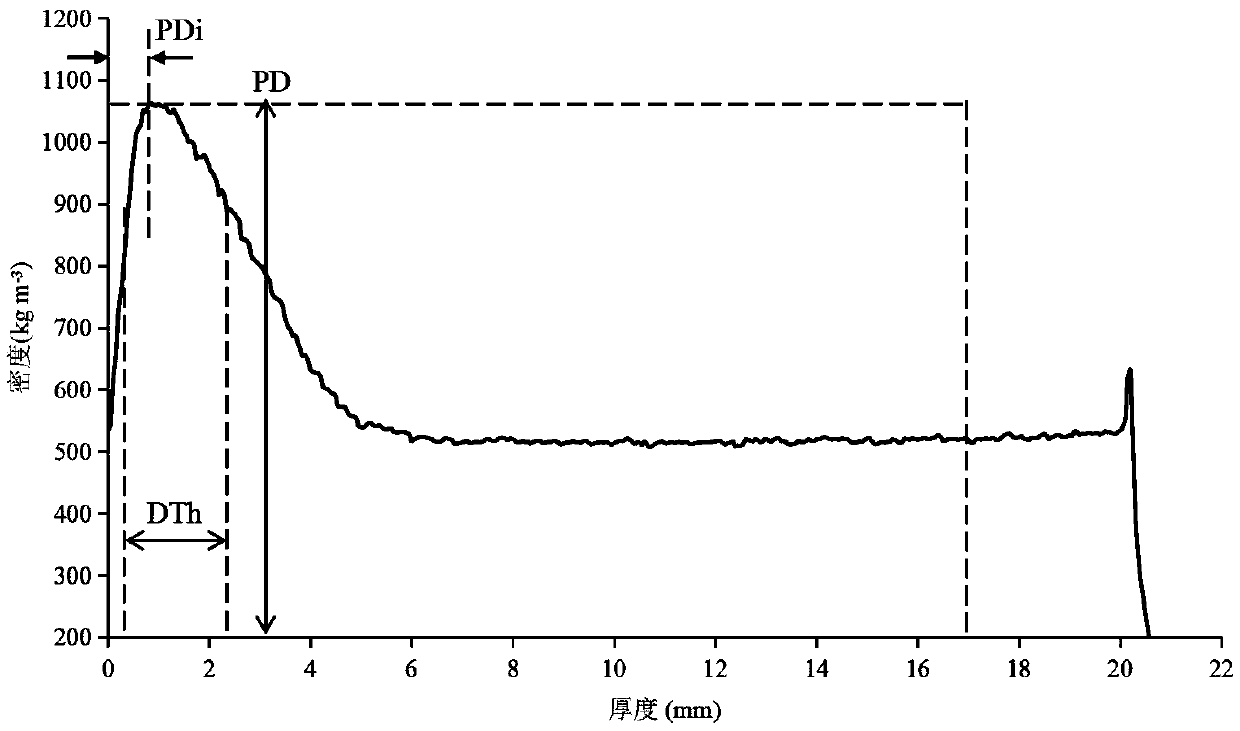

[0030] Use an X-ray profile density analyzer to detect the single-sided surface compression of poplar (a species of poplar) VDP, the scanning speed is 0.05 mm / s, and the X-ray source voltage is 29 kV; use an electronic universal testing machine to detect single-side surface compression The hardness of wood and uncompressed wood, the radius of the pressing ball is 5.64 mm, the indentation depth is 2.82 mm, and the feed rate is 5 mm / min.

[0031] figure 1 In this implementation, the cross-sectional density distribution (VDP) of the one-sided surface layer of Populus tomentosa is compressed, wherein the distance (PDi) from the peak density position to the compressed surface is 0.85 mm, and the peak density (PD) is 1062.7 kg / m 3 , the thickness of the core dense layer (DTh) is 2.02 mm, PD / DTh is 526, the hardness of the compressed wood on one side of the surface is 3680 Newtons, and the hardness of the uncompressed wood is 1800 Newtons, and the strength-to-weight ratio of the comp...

Embodiment 2

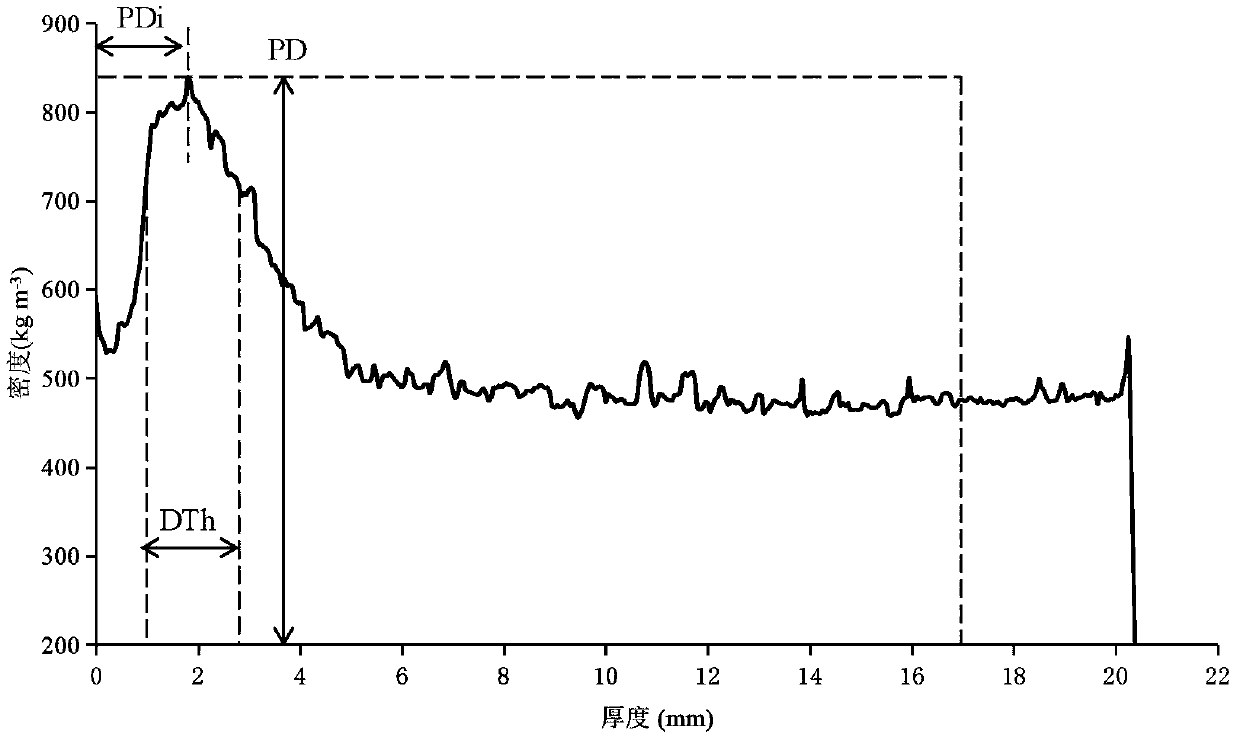

[0033] Use the X-ray profile density analyzer to detect the VDP of the compressed wood on one side of Populus tomentosa, the scanning speed is 0.05 mm / s, and the X-ray source voltage is 29 kV; use the electronic universal testing machine to detect the hardness of the compressed wood and uncompressed wood on the one-sided surface , the radius of the pressing ball is 5.64 mm, the indentation depth is 2.82 mm, and the feed speed is 5 mm / min.

[0034] figure 2 In this implementation, the cross-sectional density distribution (VDP) of the one-sided surface layer of Populus tomentosa is compressed, where PDi is 1.80 mm, and PD is 839.9 kg / m 3 , DTh is 1.96 mm, PD / DTh is 428, the hardness of compressed wood on one side surface is 3060 Newton, and the hardness of uncompressed wood is 1800 Newton, and the strength-to-weight ratio of compressed wood on one side surface is 1.5 times that of uncompressed wood.

Embodiment 3

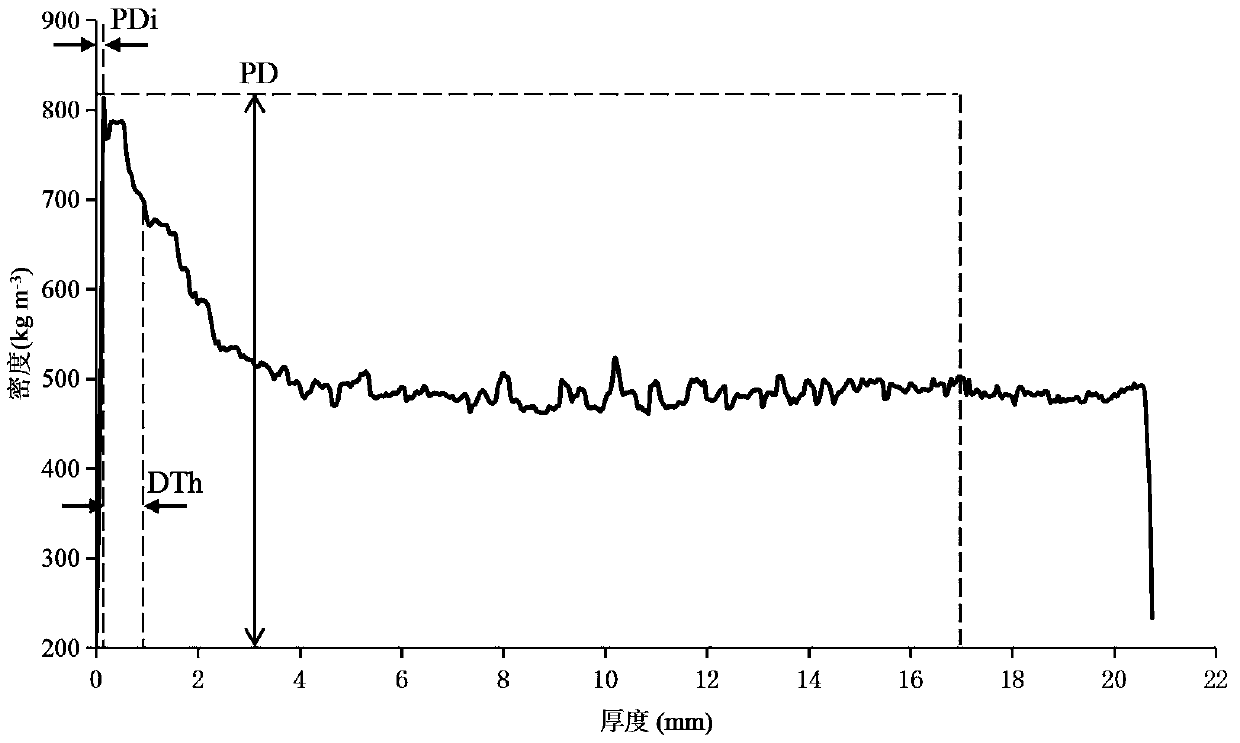

[0036] Use the X-ray profile density analyzer to detect the VDP of the compressed wood on one side of Populus tomentosa, the scanning speed is 0.05 mm / s, and the X-ray source voltage is 29 kV; use the electronic universal testing machine to detect the hardness of the compressed wood and uncompressed wood on the one-sided surface , the radius of the pressing ball is 5.64 mm, the indentation depth is 2.82 mm, and the feed speed is 5 mm / min.

[0037] image 3 In this implementation, the cross-sectional density distribution (VDP) of the one-sided surface layer of Populus tomentosa, where PDi is 0.15 mm, and PD is 811.0 kg / m 3 , DTh is 1.36 mm, PD / DTh is 596, the hardness of compressed wood on one side surface is 2660 Newton, and the hardness of uncompressed wood is 1800 Newton, and the strength-to-weight ratio of compressed wood on one side surface is 1.3 times that of uncompressed wood.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com