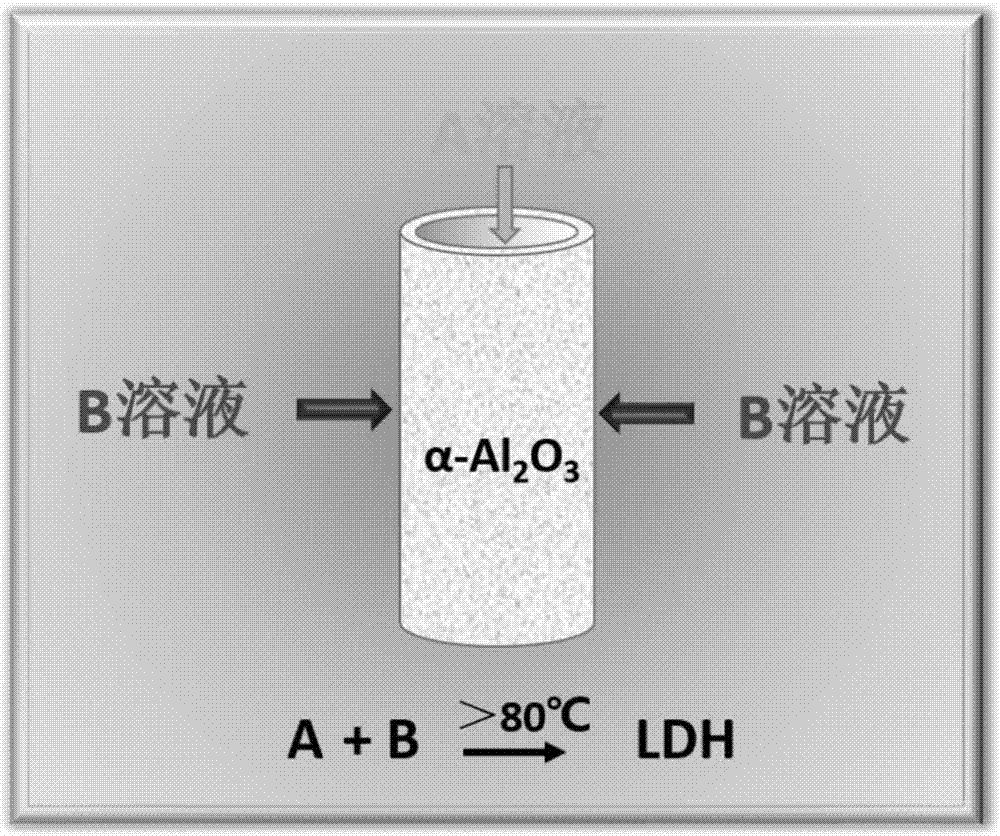

Method for preparing hydrotalcite composite film by back diffusion technology

A reverse diffusion and hydrotalcite technology is applied in the field of membrane separation to achieve the effects of enhanced operation stability, simple preparation process and good binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using a commercial porous membrane as α-Al 2 o 3 The material, in the form of a three-dimensional tube, has a membrane area of 10 cm 2 . The selected hydrotalcite is CoAl-CO 3 , whose precursor metal ions are cobalt nitrate and zinc nitrate, to which urea and ammonium fluoride need to be added as buffer reagents and etchant.

[0024] Preparation method of hydrotalcite ceramic composite membrane:

[0025] (1) To pretreat the commercial tubular ceramic substrate, first soak the ceramic substrate in pure hydrochloric acid for 30 minutes, rinse with deionized water and ultrasonically vibrate to remove the residual acid in the membrane pores;

[0026] (2) Soak the pickled ceramic substrate in ammonia solution for 30 minutes, rinse with deionized water and ultrasonically vibrate to remove the residual alkali in the membrane pores, and then place the ceramic substrate in an oven at a certain temperature to dry for use;

[0027] (3) cobalt nitrate and aluminum nitrate ar...

Embodiment 2

[0033] Using a commercial porous membrane as α-Al 2 o 3 The material, in the form of a three-dimensional tube, has a membrane area of 10 cm 2 . The selected hydrotalcite is CoAl-CO 3 , whose precursor metal ions are cobalt nitrate and zinc nitrate, to which urea and ammonium fluoride need to be added as buffer reagents and etchant.

[0034] Preparation method of hydrotalcite-like ceramic inorganic composite membrane:

[0035] (1) To pretreat the commercial tubular ceramic substrate, first soak the ceramic substrate in pure hydrochloric acid for 30 minutes, rinse with deionized water and ultrasonically vibrate to remove the residual acid in the membrane pores;

[0036] (2) Soak the pickled ceramic substrate in ammonia solution for 30 minutes, rinse with deionized water and ultrasonically vibrate to remove the residual alkali in the membrane pores, and then place the ceramic substrate in an oven at a certain temperature to dry for use;

[0037] (3) Dissolve cobalt nitrate...

Embodiment 3

[0043] Using a commercial porous membrane as α-Al 2 o 3 The material, in the form of a three-dimensional tube, has a membrane area of 10 cm 2 . The selected hydrotalcite is CoAl-CO 3 , whose precursor metal ions are cobalt nitrate and zinc nitrate, to which urea and ammonium fluoride need to be added as buffer reagents and etchant.

[0044] Preparation method of hydrotalcite-like ceramic inorganic composite membrane:

[0045] (1) To pretreat the commercial tubular ceramic substrate, first soak the ceramic substrate in pure hydrochloric acid for 30 minutes, rinse with deionized water and ultrasonically vibrate to remove the residual acid in the membrane pores;

[0046] (2) Soak the pickled ceramic substrate in ammonia solution for 30 minutes, rinse with deionized water and ultrasonically vibrate to remove the residual alkali in the membrane pores, and then place the ceramic substrate in an oven at a certain temperature to dry for use;

[0047] (3) Dissolve cobalt nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Membrane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com