Method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing by quartz tube

A directional solidification, quartz tube technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of reduced industrial production costs, high cutting equipment costs, affecting purification effects, etc. Energy consumption and the effect of reducing process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

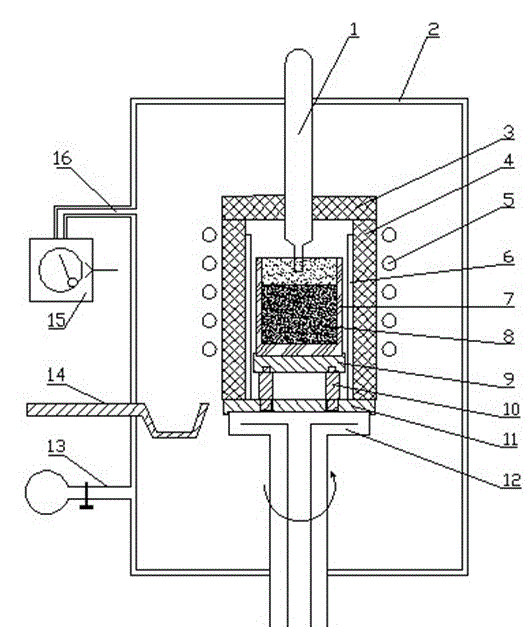

[0023] Such as figure 1 The equipment used in the method of directional solidification and purification of polysilicon by taking tailings from quartz tubes is shown. The outer wall is composed of a vacuum chamber 2, and a vacuum pipeline 16 is installed on the outer wall. One end of the vacuum pipeline 16 is connected to a vacuum pump group 15.

[0024] A ventilation pipeline 13 is fixedly installed on the outer wall, and a tailings collection box 14 is installed movably. The water cooling plate 12 is movably installed at the bottom of the vacuum chamber 2. The graphite plate 11 is placed on the top of the water cooling plate. One end of the pillar 10 is nested and connected to the graphite plate 11 through a hole, and the other end is nested and connected to the graphite tray 9. The crucible 7 is placed on the graphite tray 9, and the graphite heating element 6 is set on the periphery of the crucible and fixed on the side wall of the vacuum chamber 2. , 4 sets of carbon felt ...

Embodiment 2

[0029] Use the equipment described in Example 1 to take the tailings and carry out directional solidification to purify polysilicon. First, add silicon material with a purity of 99.5% to the crucible 7 with 90% of the volume of the crucible, close the ventilation line 13, and turn on the vacuum pump group 15. The vacuum degree in the vacuum chamber 2 is pumped to 10Pa, close the vacuum pump group 15, open the ventilation pipeline, fill the vacuum chamber 2 with 99.92% argon until the pressure reaches 100Pa, and close the ventilation pipeline;

[0030]The second step of smelting and solidification: turn on the power, use the induction coil 5 and the graphite heating element 6 to heat the silicon material in the crucible 7 to 1450 ° C until it is completely melted into a silicon melt, keep it at this temperature for 30 minutes, and pull it vertically downward The water cooling plate 12 makes the silicon melt in the crucible 7 move vertically downward at a constant speed at a spee...

Embodiment 3

[0033] Use the equipment described in Example 1 to take tailings and carry out directional solidification to purify polysilicon. First, add silicon material with a purity of 99.7% to the crucible 7 with a volume of 93% of the crucible, close the ventilation line 13, and turn on the vacuum pump group 15. The vacuum in the vacuum chamber 2 is pumped to 2 Pa, the vacuum pump group 15 is closed, the ventilation pipeline is opened, and the vacuum chamber 2 is filled with argon gas with a purity of 99.94% until the pressure reaches 2000 Pa, and the ventilation pipeline is closed;

[0034] The second step of smelting and solidification: turn on the power, use the induction coil 5 and the graphite heating element 6 to heat the silicon material in the crucible 7 to 1550 ° C until it is completely melted into a silicon melt, keep it at this temperature for 45 minutes, and pull it vertically downward The water cooling plate 12 makes the silicon melt in the crucible 7 move vertically downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com