Patents

Literature

54results about How to "Easy to retrofit and install" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

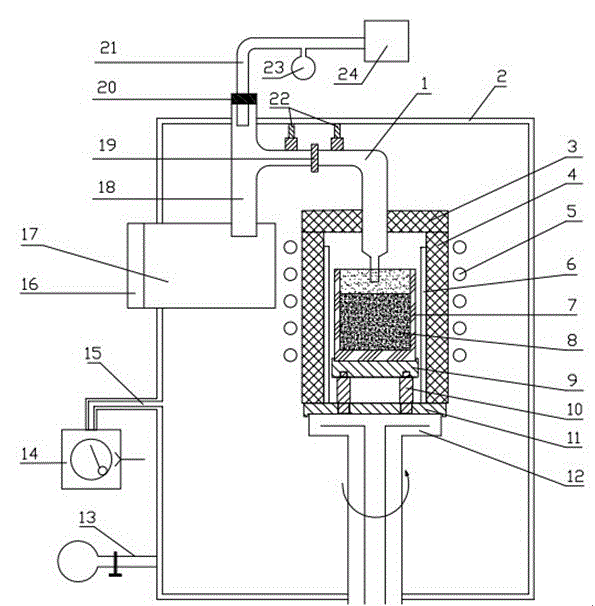

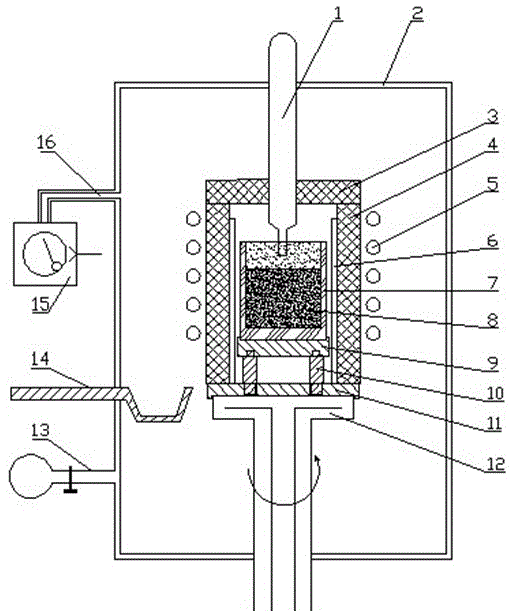

Method and equipment for rapid collection and purification of polycrystalline silicon through directional solidification of tailing

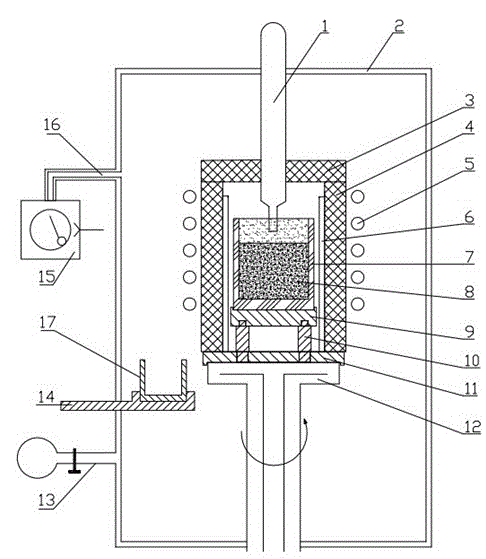

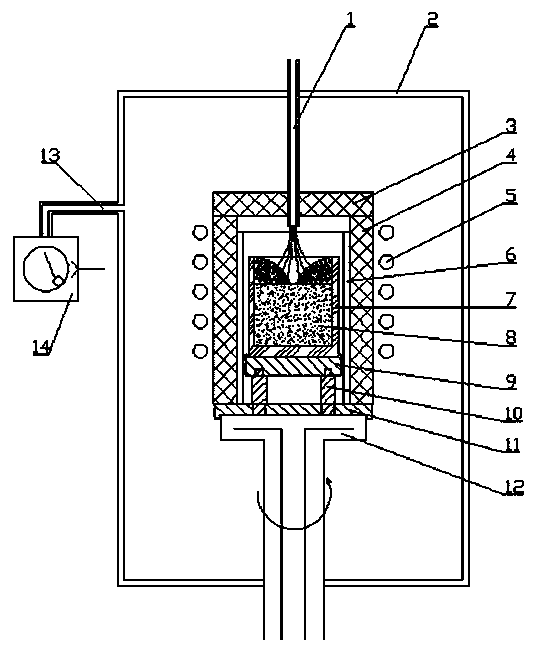

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing. According to the method, under the inert gas shielding environment, abluent silicon is heated to be fully melted so as to carry out directional solidification; ingot pulling is stopped when solidification is completed by 85-90%, a graphite bent pipe is stretched into surplus unset silicon at the upper layer, then the other end of the graphite bent pipe is vacuumed through a vacuum unit, so that the surplus unset silicon at the upper layer enters the graphite bent pipe under the action of pressure difference and enters a water cooling collection box through the guide of the graphite bent pipe; heating is stopped after all the surplus unset silicon at the upper layer enters the water cooling collection box, and cast ingot solidified in a crucible is silicon cast ingot of high purity. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, and a tailing collection device can be used repeatedly, can collect more tailings, and is safe and reliable.

Owner:QINGDAO NEW ENERGY SOLUTIONS

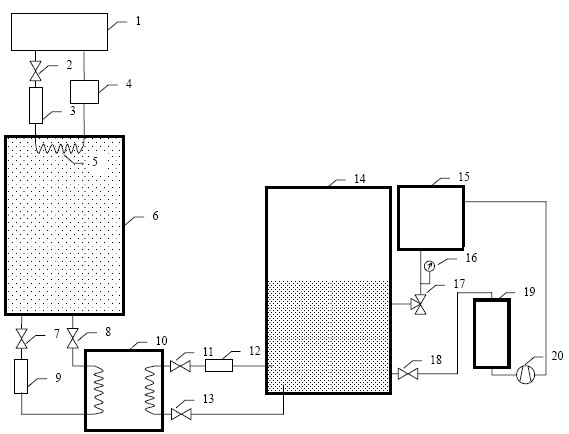

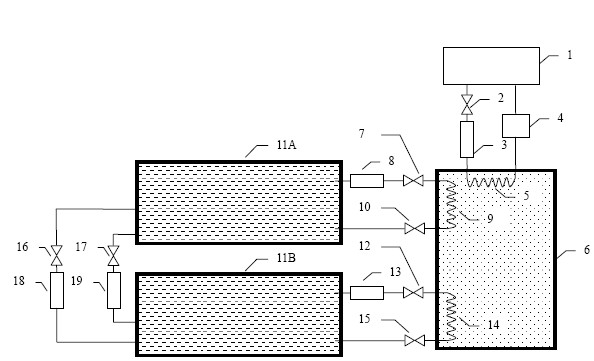

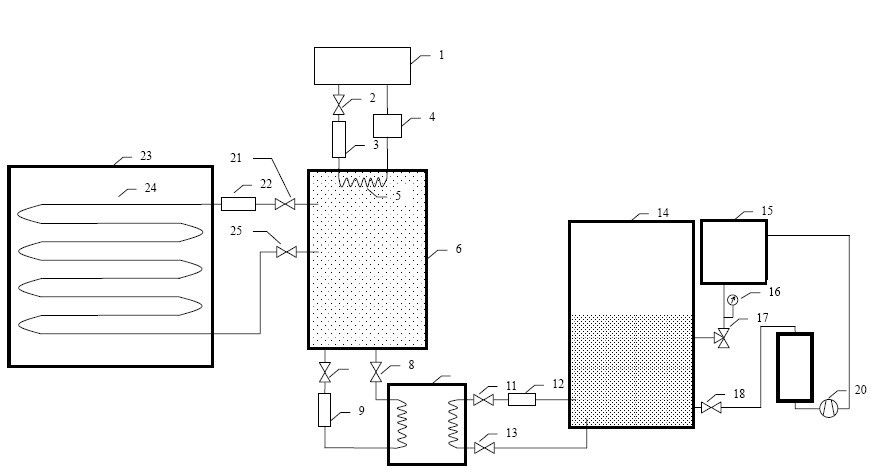

Method and device for keeping fresh aquatic products by cold accumulation on board

InactiveCN102009740AReduce energy consumptionLower fishing costsAuxillariesLighting and heating apparatusSeawaterSaline water

The invention discloses a method for keeping fresh aquatic products by cold accumulation on board, which comprises the following steps of: keeping cold brine in a cold accumulation tank at the temperature of -30 to -5 DEG C in advance by using an onboard cooling system, performing indirect cold heat exchange on seawater in a cooling tank and the brine in the cold accumulation tank to decrease the temperature of the seawater in the cooling tank to 10 to -10 DEG C, and quickly cooling catches in the cooling seawater tank to the central temperature of-5 to 10 DEG C to meet cooling requirements. The invention also provides a device for keeping fresh the aquatic products by cold accumulation on board, which comprises the cold accumulation tank, the cooling seawater tank and the onboard cooling system. The method and the device for keeping fresh the aquatic products by cold accumulation on board are effectively adapted to onboard operation, reduce energy consumption and cost and improve the fresh-keeping quality.

Owner:ZHEJIANG UNIV OF TECH

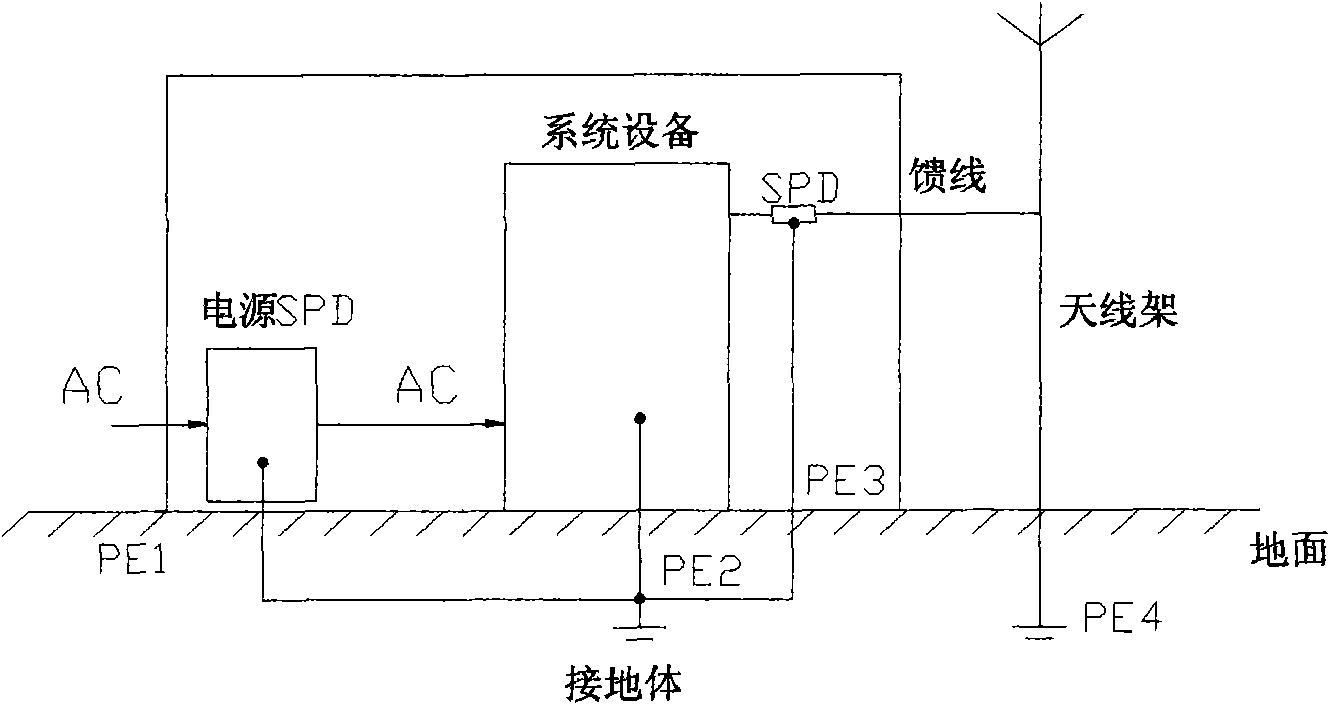

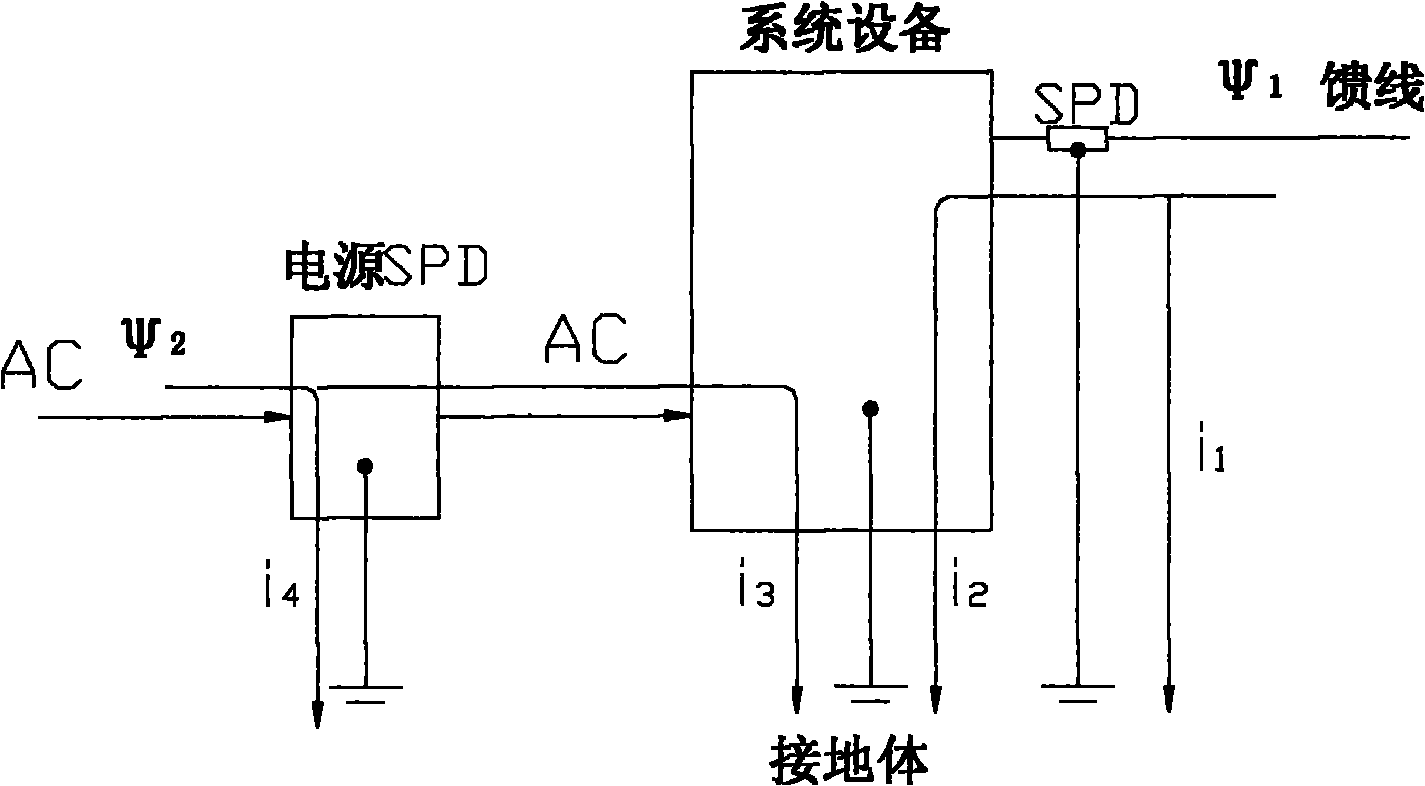

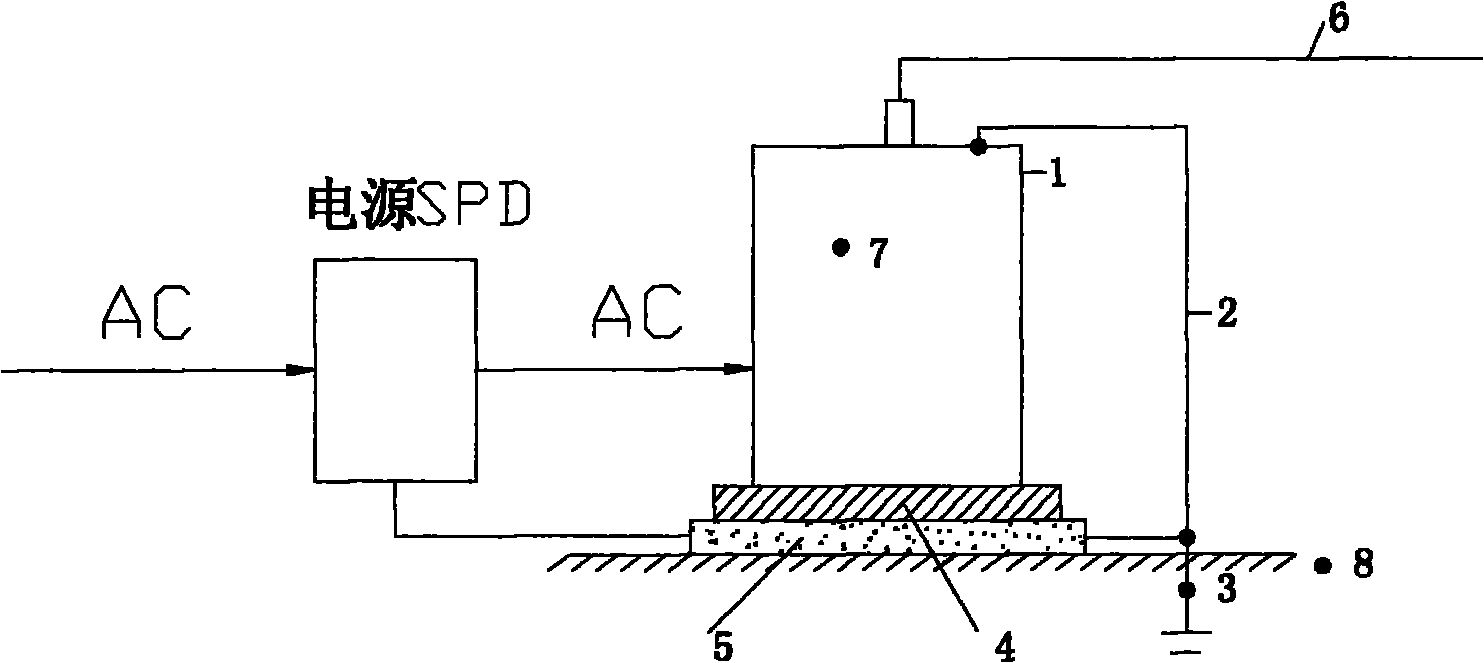

Lightning protection method by grounding nearest point of signal feeder port

InactiveCN101944738AEliminate lightning potentialEnsure safetyEmergency protective arrangements for limiting excess voltage/currentConnection contact member materialCurrent channelEngineering

The invention relates to a lightning protection method by grounding the nearest point of a signal feeder port, which comprises a nearest grounding point of the signal feeder port, a down lead, an insulating material and a metal grounding plate, wherein one end of the down lead is connected with the nearest grounding point of the signal feeder port, the other end is connected with a grounding body, a housing of a system device is isolated with the ground by using the insulating material, a layer of the metal grounding plate is laid below the insulating material, the metal plate is connected with the grounding body, and the sizes of the metal plate and the insulating material are at least larger than the contactable human-machine distance. The lightning protection method has the benefits of eliminating a bleeder dissipation current channel formed by lightning potential introduced from a power supply and a signal interface through the housing at the lower part of a machine device and the ground, leading the ground potential of the housing at the lower part of the device to suspend by leading the housing at the lower part of the device to be insulated and isolated with the ground, eliminating the probability of leading the external lightning potential to form lightning current and pass through in the system device, leading the place within a certain range below the system device to form the isopotential surface through the metal plate by utilizing the metal plate laid below the insulating plate and further ensuring the personal safety of staff walking on the system device. The method has high protection reliability and maintenance-free property and can simultaneously effectively reduce the mounting cost and the construction cost of the system.

Owner:HANGZHOU BILEI TECH

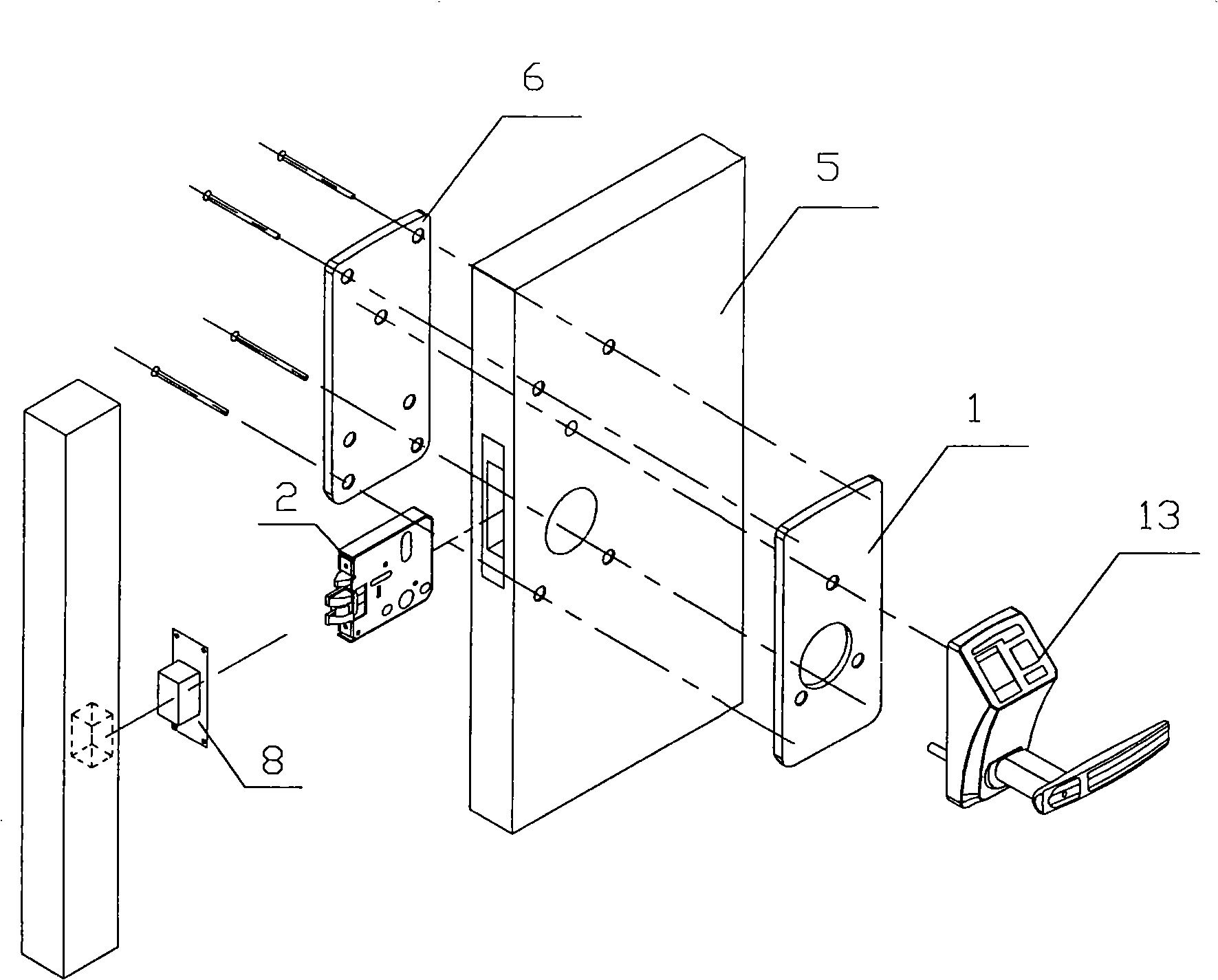

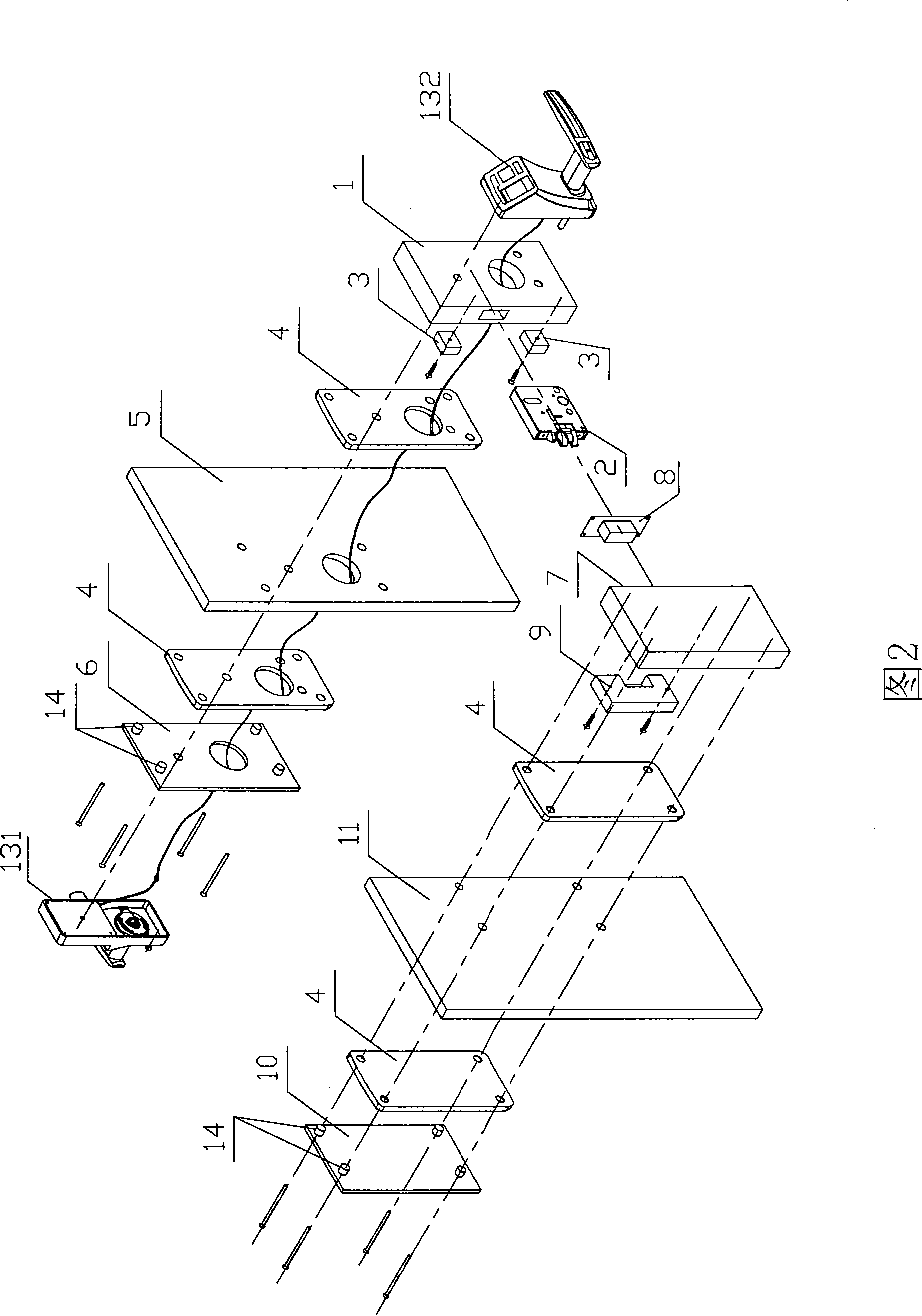

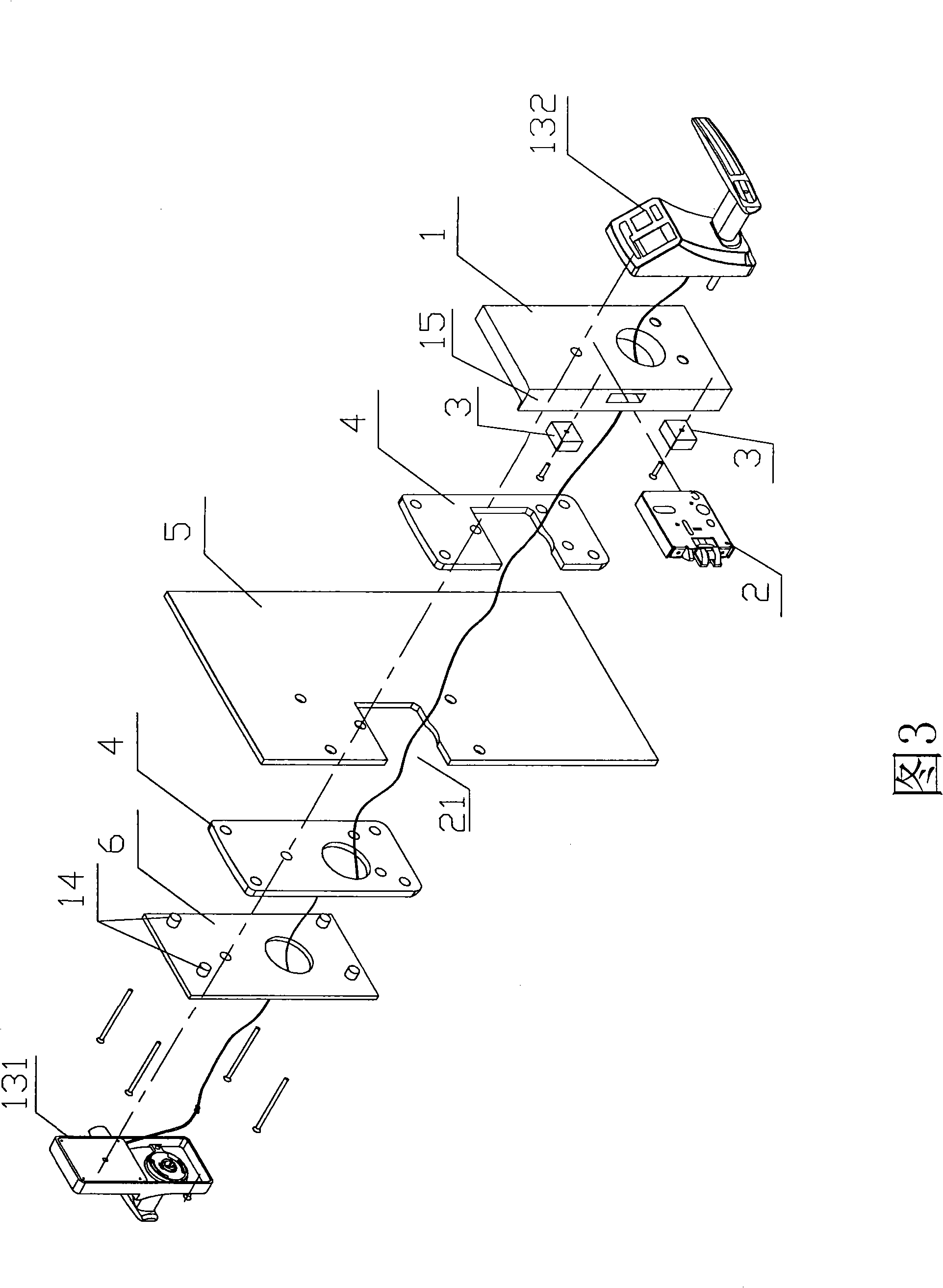

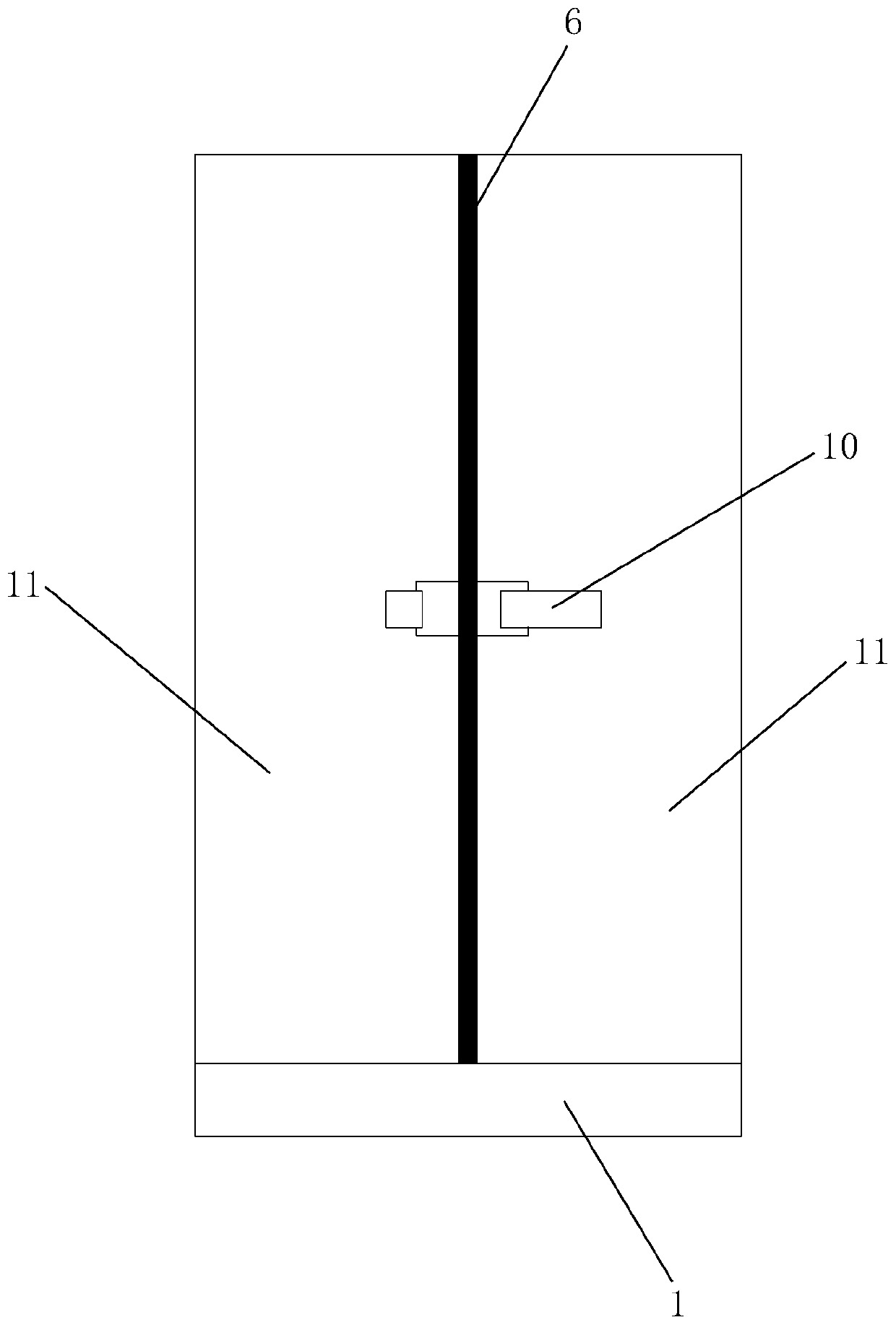

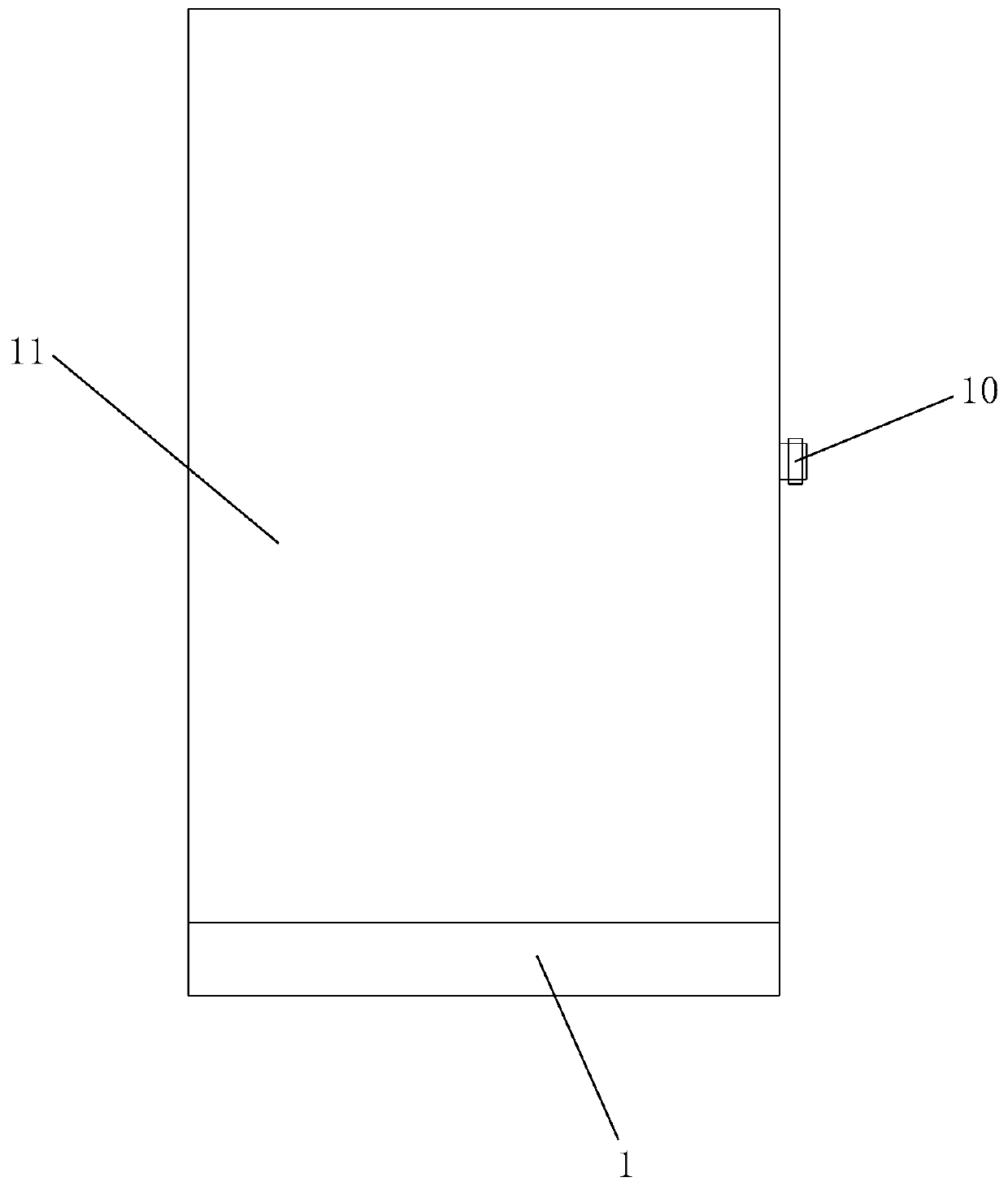

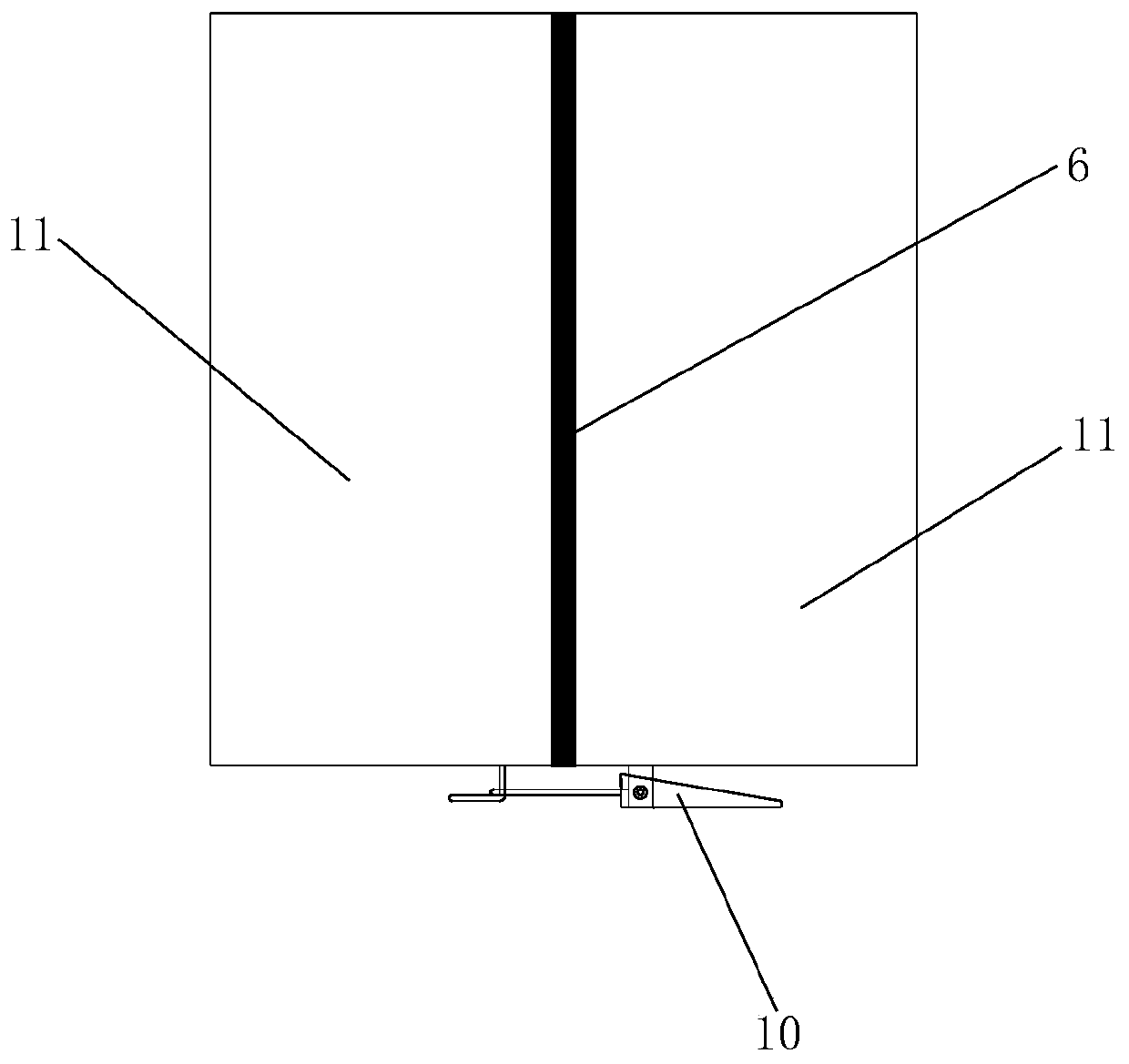

Installation structure of electronic lock

InactiveCN101255777ANeat appearanceReduce complexityElectric permutation locksSoftware engineeringFastener

The present invention discloses an installation structure of an electronic lock which comprises an electronic control unit box. The invention is characterized in that the structure also comprises two separated inner fixing plate and external fixing plate. The inner fixing plate and the external fixing plate can traverse the door leaf through the fastener and are oppositely installed and fixed on two sides of the door leaf. The electronic control unit box is detachably fixed on the external surface of the external fixing plate or the inner fixing plate. The invention has the characteristics of simple structure, convenient and reliable installation, wider installation range of the electronic lock and the like. The invention is widely applied on the installation of the electronic lock in various kinds of door, the installation of traditional core inserting door lock and the improvement and change of the old lock.

Owner:曹湛斌

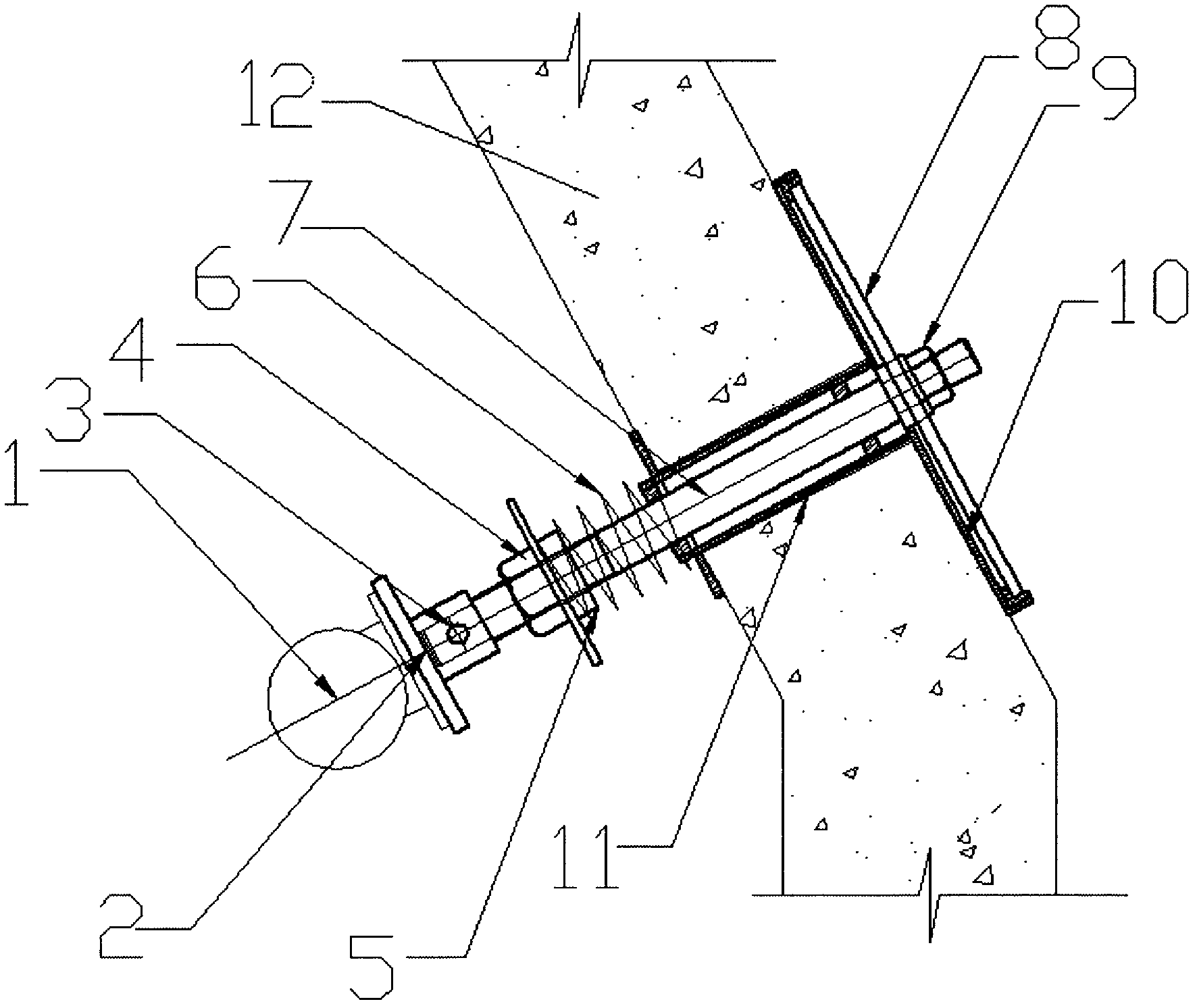

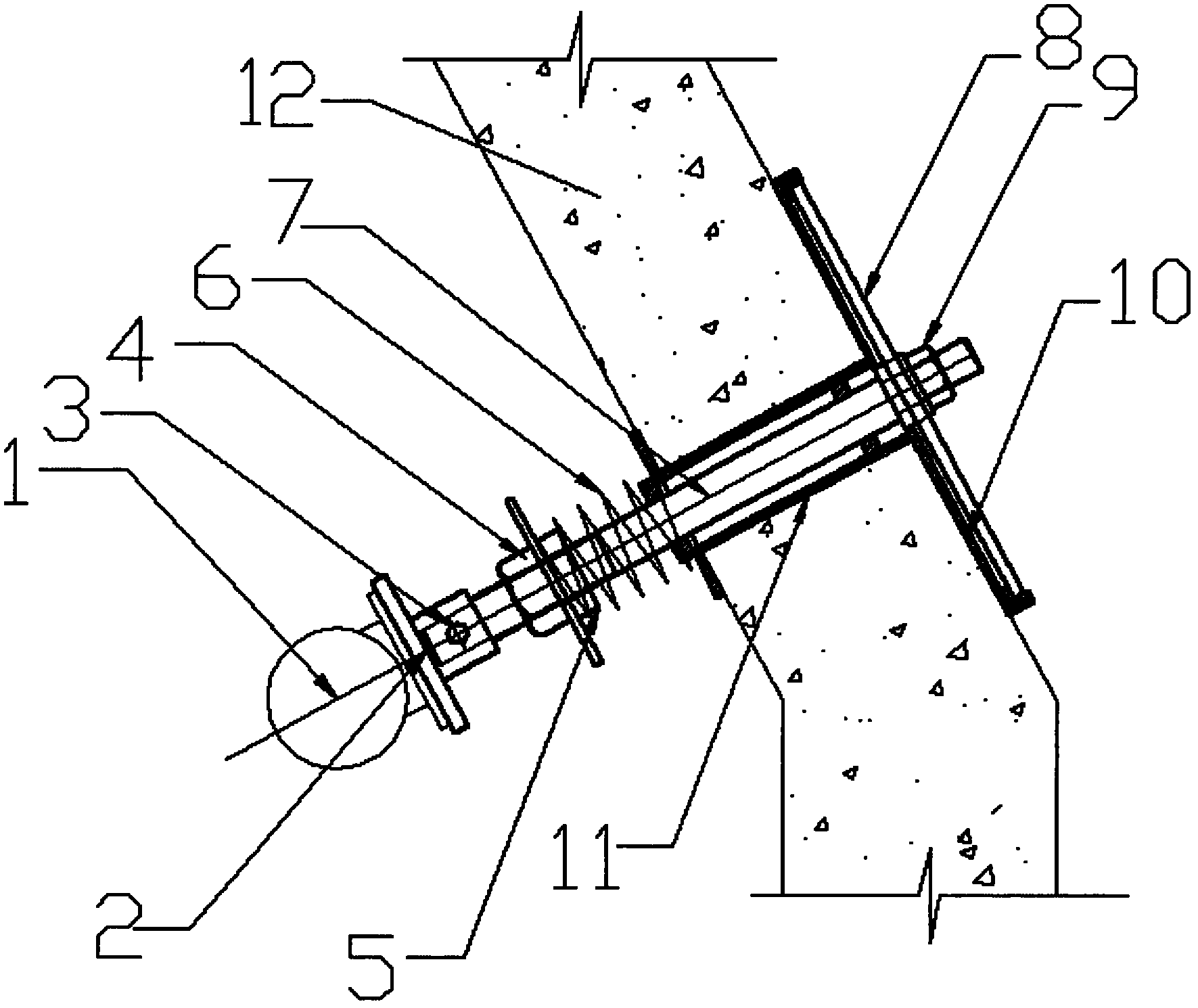

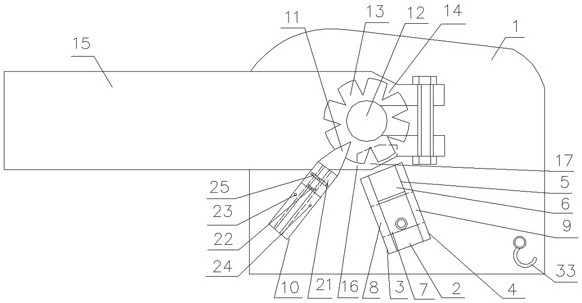

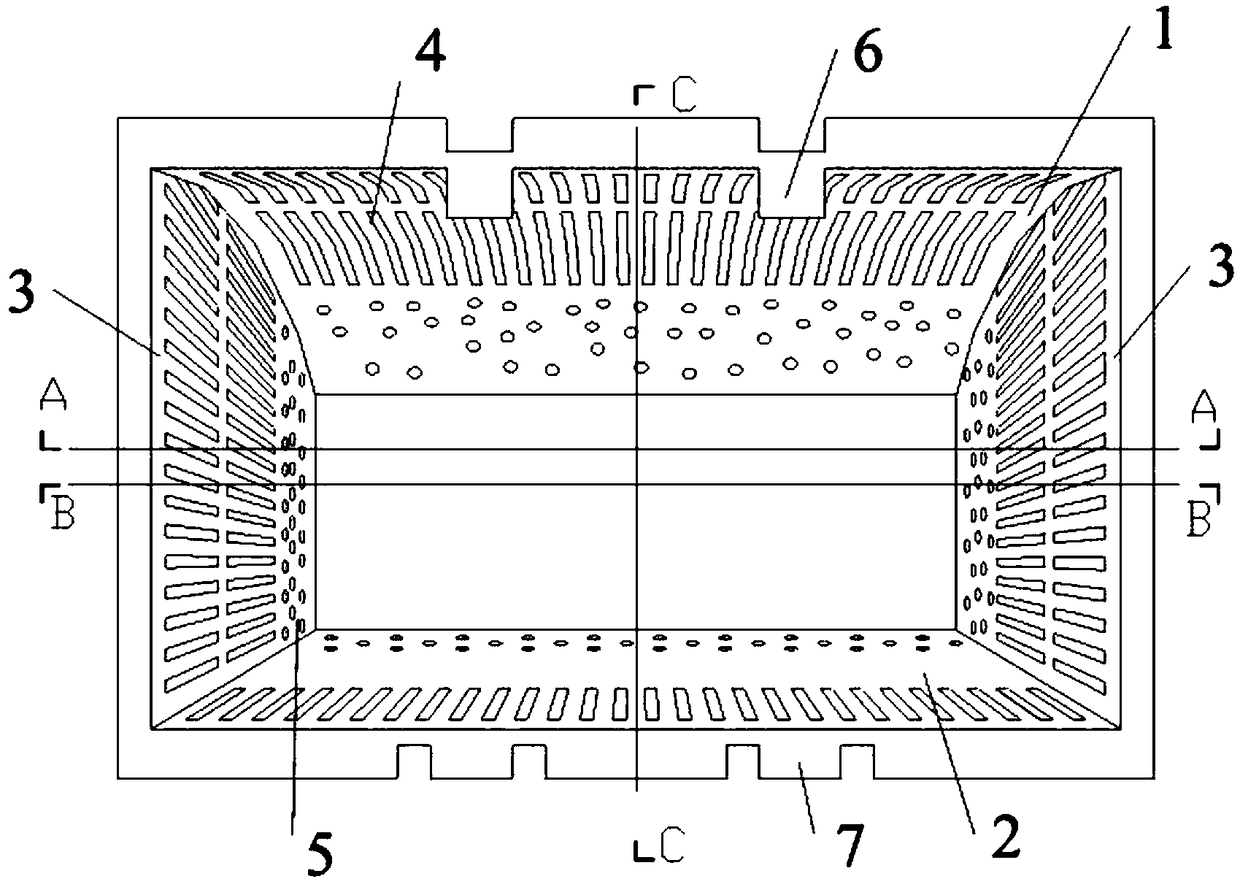

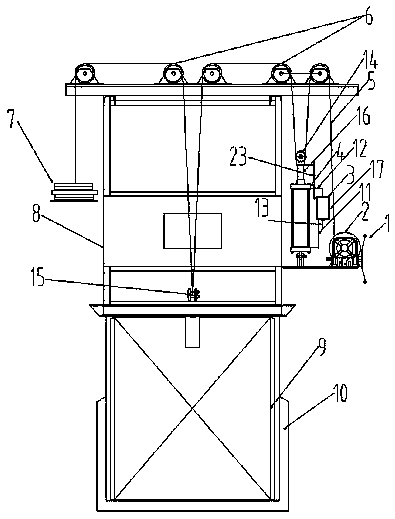

Coal bunker wall vibrating device

InactiveCN102020075ASimple structureEasy to retrofit and installLarge containersVibration amplitudeElectric machinery

The invention relates to a coal bunker wall vibrating device which is characterized in that a fixing base plate (10) is welded on the inner wall of a bunker wall (12), holes are correspondingly formed on the fixing base plate (10) and the bunker wall (12), a middle sleeve (11) is placed in the holes, a vibration connecting rod (7) is placed in the middle sleeve (11), one end of the vibration connecting rod (7) is provided with a vibrating plate (8), the vibrating plate (8) is fixed on the vibration connecting rod (7) by nuts (9), a vibration motor (1) and a vibration motor base (2) are connected with the other end of the vibration connecting rod (7) by fixed pins (3), a puller spring (6) is arranged outside of the vibration connecting rod (7), the puller spring (6) is fixed by puller nuts (4) and a spring collar (5), and the puller spring (6) is used for amplifying vibration amplitude of the vibration motor (1), so that the vibrating plate (8) in the bunker vibrates in a reciprocating way. The device provided by the invention has simple structure and can be transformed, installed and regulated conveniently; and compared with the prior art, the device has substantial characteristics and progress, can effectively solve the problems of material binding and material blockage in the bunker, and has strong practicability.

Owner:SHANDONG IRON & STEEL CO LTD

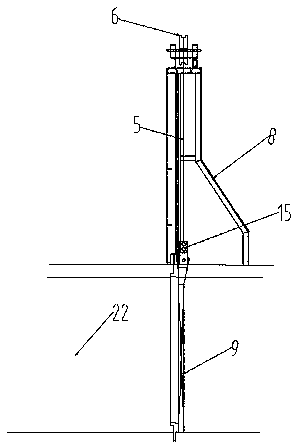

Method and equipment for controlled directional solidification and purification of polycrystalline silicon through taking tailing by graphite tube

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing. According to the method, under the inert gas shielding environment, abluent silicon is melted so as to carry out directional solidification; ingot pulling is stopped when solidification is completed by 85-90%, a graphite tube is stretched into surplus melt silicon, then inert gas is led into a vacuum chamber, so that the surplus melt silicon enters the graphite pipe under the action of pressure difference and ingot pulling is continuously carried out, after the upper end of a crucible leaves a heating area, the water cooled crucible is stretched below the graphite tube, inert gas is stopped being led into the vacuum chamber, the vacuum chamber is vacuumed, the surplus melt silicon in the graphite tube falls into the water cooled crucible to be cooled and solidified; the power is cut off so as to stop heating, and cast ingot solidified in a crucible is silicon cast ingot of high purity. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, is easy to operate, can effectively remove impurities accumulated at the tail of the cast ingot, saves production period and cost, and is applicable to industrial production.

Owner:QINGDAO NEW ENERGY SOLUTIONS

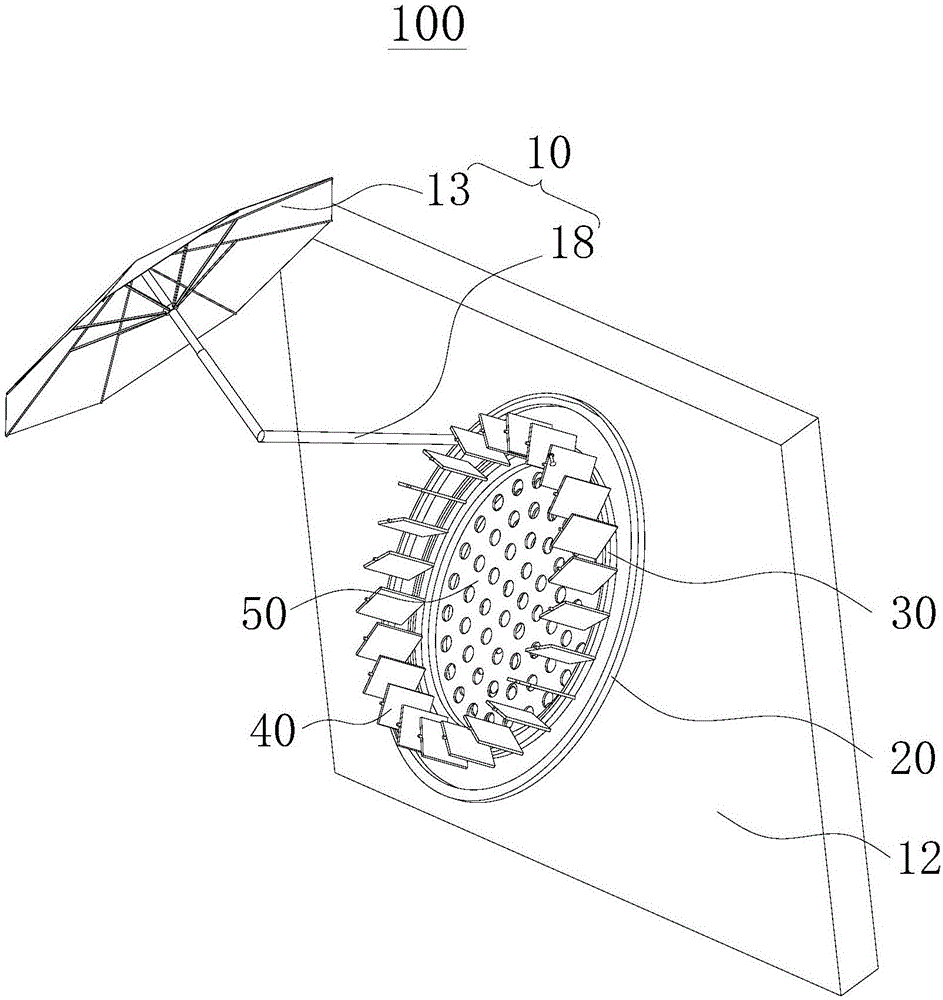

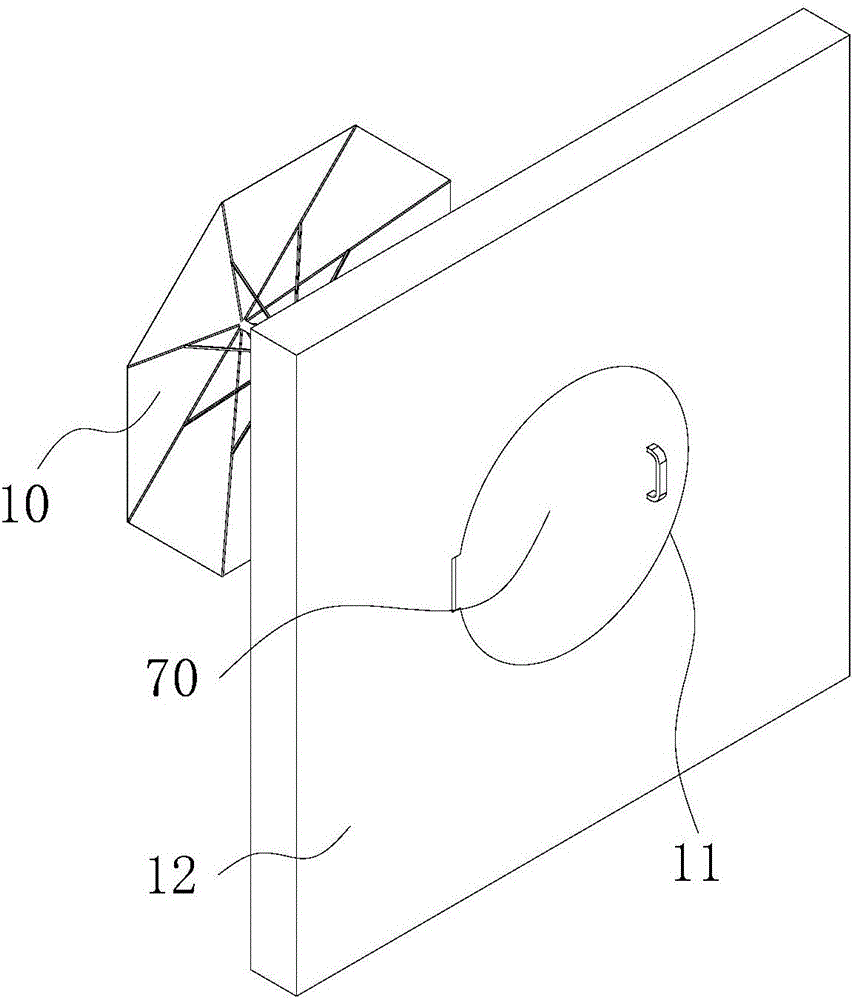

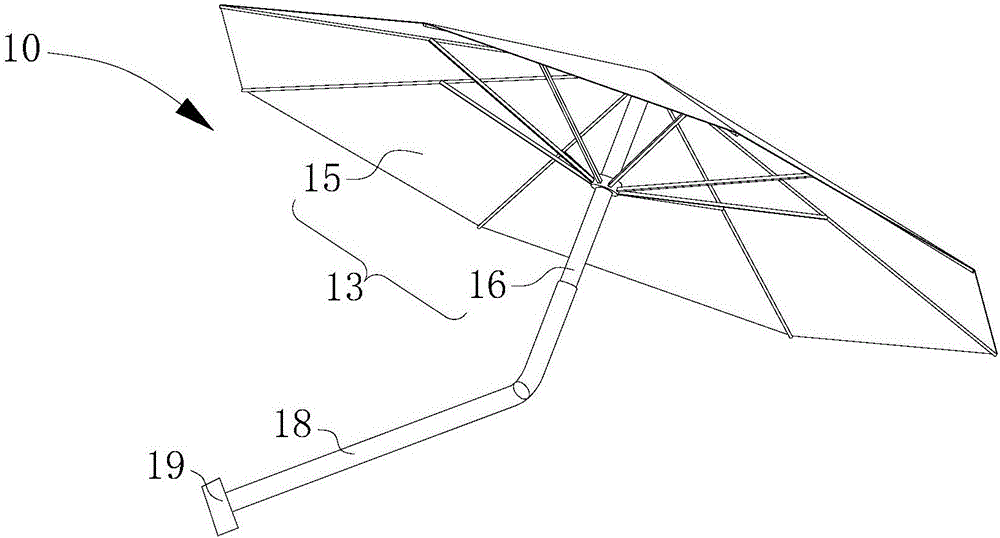

Ventilation window and peripheral ventilation support parts

InactiveCN106639822AGuaranteed circulationBlock sunlightVentilation arrangementNatural ventilationEngineering

The invention provides a ventilation window and peripheral ventilation support parts, and relates to the field of ventilation window. The ventilation window is arranged in the peripheral support parts of a building with ventilation holes. The periphery support parts of the buildings comprise building peripheral walls, traditional peripheral wall windows or other peripheral structures. Each ventilation window comprises a hiding part, a first guide rail, Venetian blinds, a second guide rail, a smooth wind part and a close door. The hiding part is slidingly arranged on the first guide rail, and is provided with the brace-open state, anti-rain semi-open state and a closed state. The Venetian blinds are rotationally arranged on the second guide rail, and are provided with the open state and the closed state. The peripheral ventilation support parts comprise the ventilation windows and other peripheral support part wherein the ventilation windows are located. Ventilation holes are arranged in the peripheral support parts, and correspond to the ventilation holes. No matter the weather is sunny day, heavy wind or strong rainstorm, the ventilation windows not only can block the rain and sunshine from all directions, but also can ventilate in a natural manner.

Owner:SICHUAN INSITITUTE OF BUILDING RES

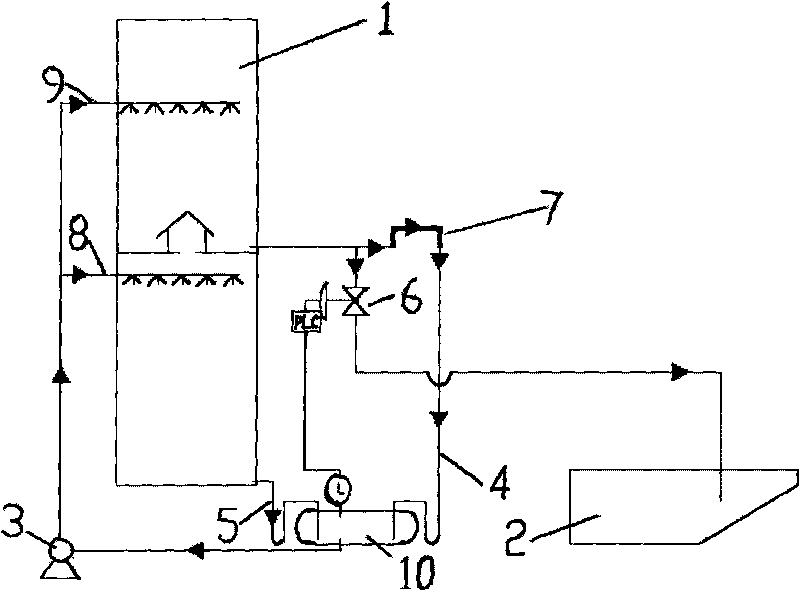

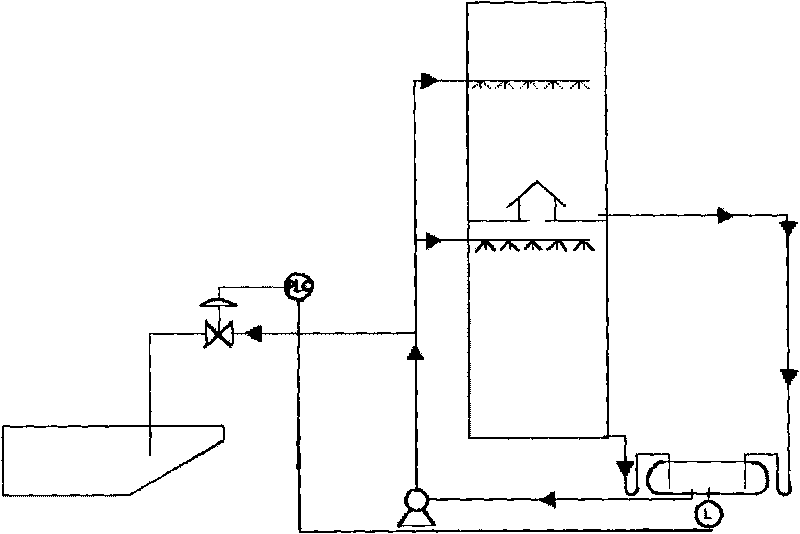

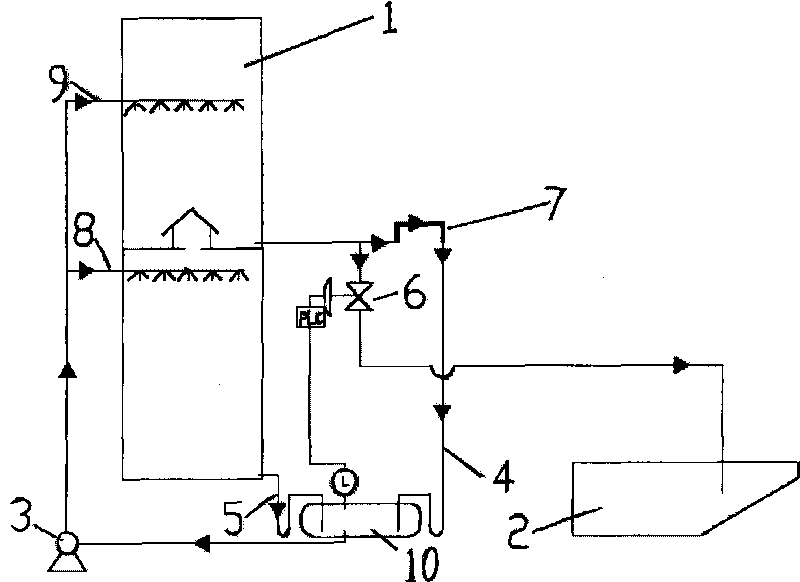

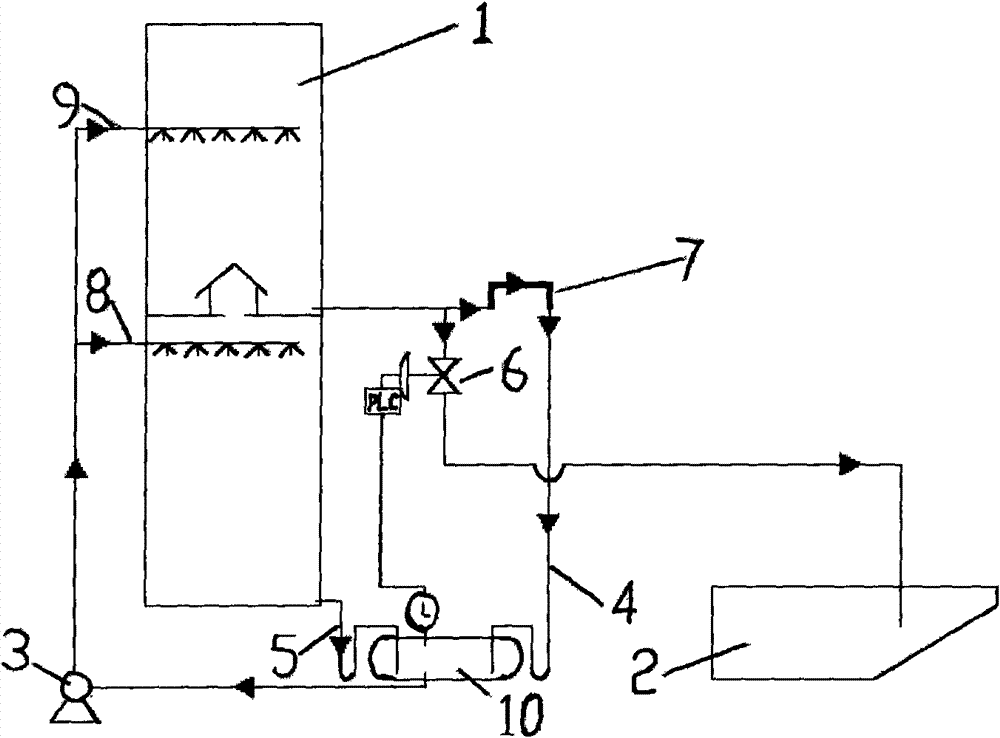

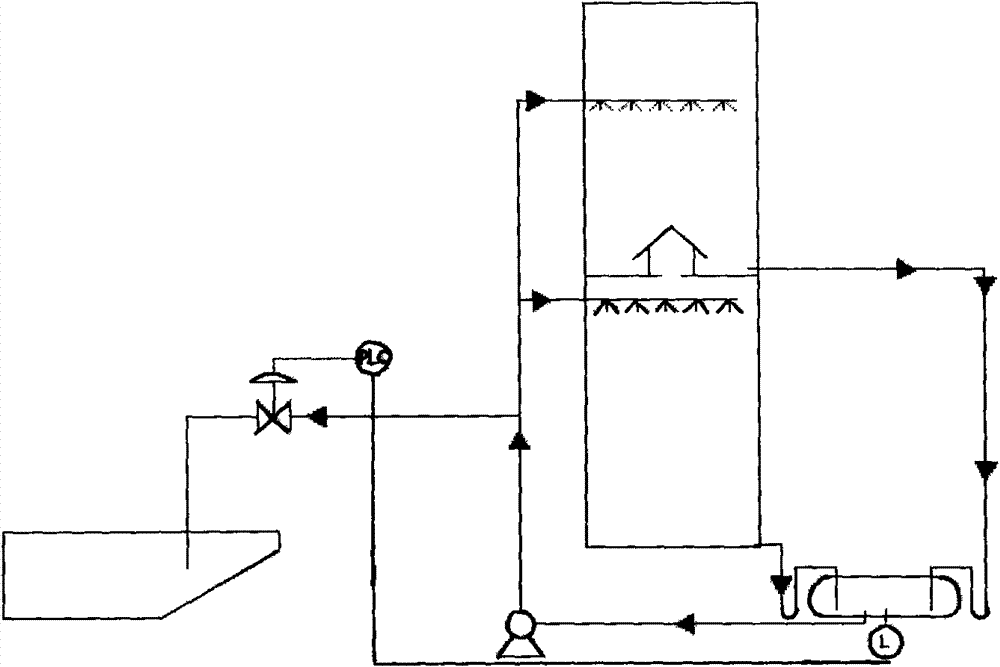

Gravity-flow type efflux technology of condensate of coal gas primary cooler

InactiveCN101698806AEasy to operateAvoid pollutionGas purification by non-gaseous materials condensationGravity flowHeight difference

The invention relates to a gravity-flow type efflux technology of condensate of a coal gas primary cooler, a liquid flow direction selector is arranged on an upper-section oil return pipeline, two ends of the liquid flow direction selector are communicated with a cross-pipe primary cooler and a circulating oil tank respectively, an automatic regulating valve is series-connected at the end of connecting the liquid flow direction selector with the cross-pipe primary cooler through a pipeline, and the two ends of the automatic regulating valve are communicated with the cross-pipe primary cooler and a mechanized settling tank respectively; the mounting position of the liquid flow direction selector is higher than a horizontal part of the upper-section oil return pipeline; the automatic regulating valve is sequentially connected with a PLC program controller, a liquid level meter and the circulating oil tank by using signal lines; and the automatic efflux of the condensate can be realized by utilizing the height difference between the upper-section oil return pipeline and the mechanized settling tank and the liquid flow direction selector, thereby reducing loads of a circulating spray pump, stabilizing the circulating spray volume and simultaneously utilizing the automatic regulating valve for regulating the efflux volume for further controlling the liquid level of the circulating oil tank. The gravity-flow type efflux technology has simple structure, and convenient mounting and regulation, and can effectively reduce the energy consumption, stabilize the operation of the primary cooler and avoid the environmental pollution.

Owner:SHANDONG IRON & STEEL CO LTD

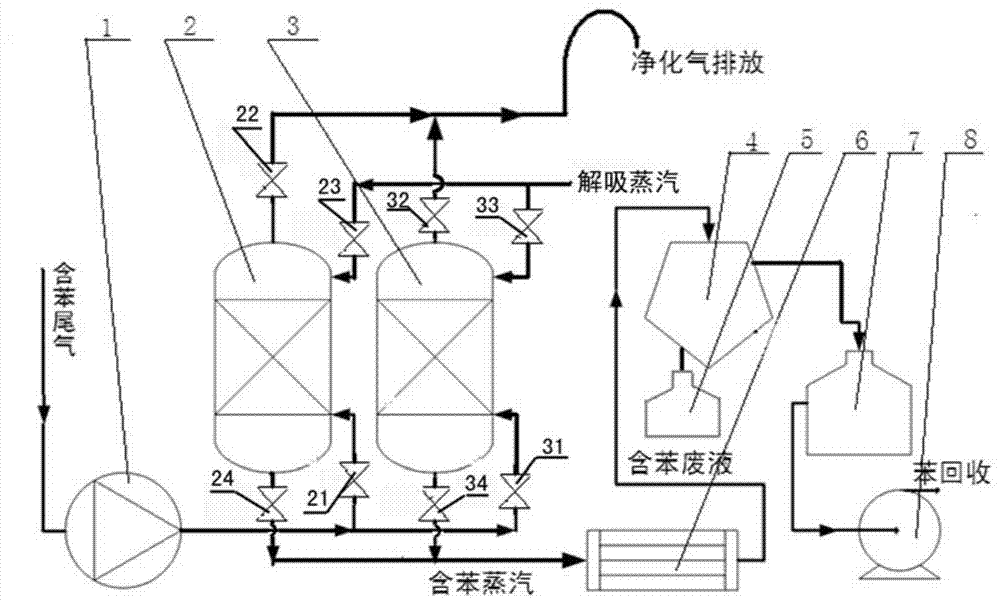

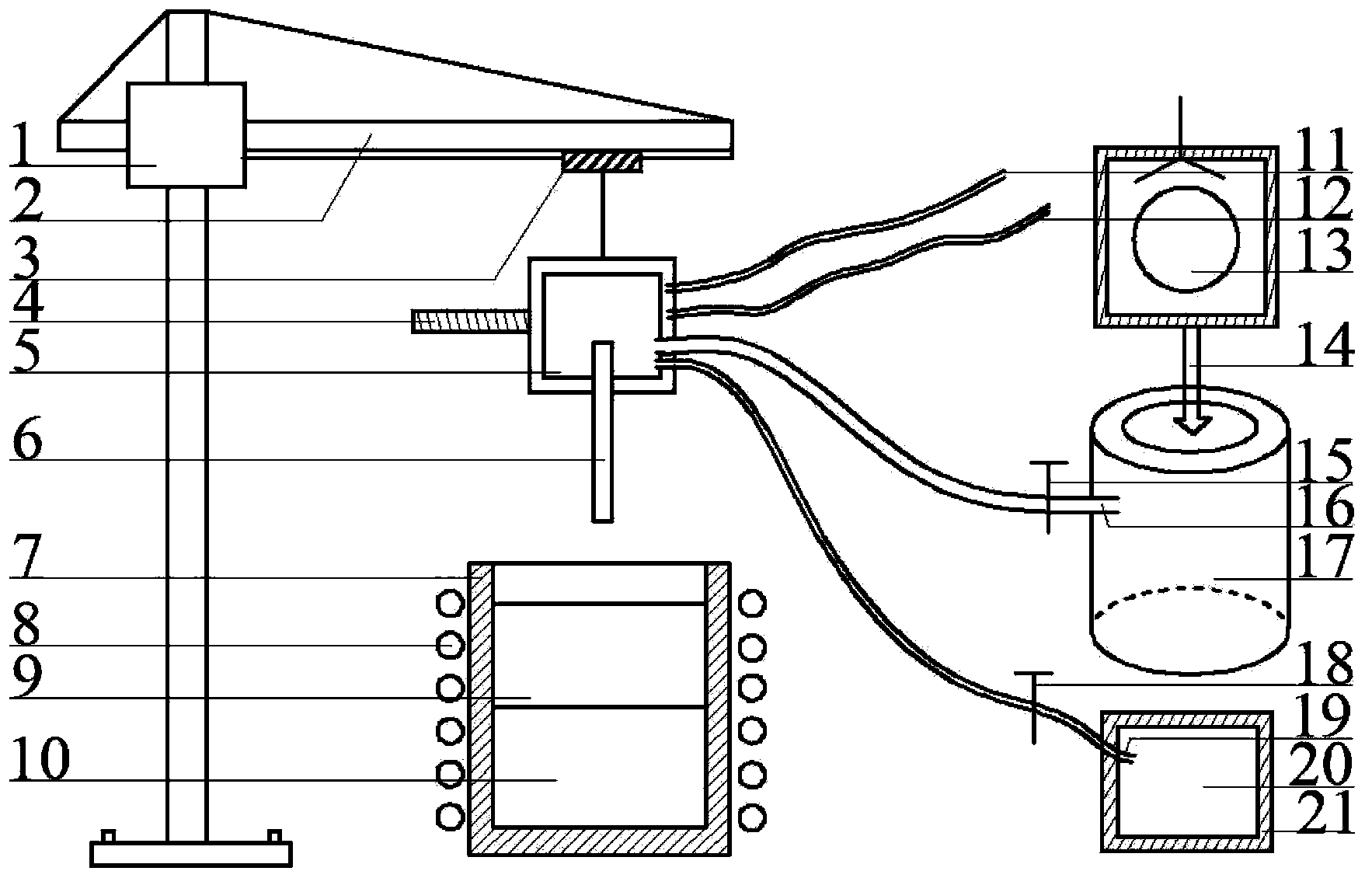

Device and method for purifying and recovering tail gas of benzene-hydrogenation truck

ActiveCN104722175ASimple structureEasy to retrofit and installDispersed particle separationLiquid separationBenzeneSorbent

The invention discloses a device and a method for purifying and recovering the tail gas of a benzene-hydrogenation truck. The device comprises a tail-gas fan, N absorbing tanks, a purified-gas discharging pipeline, a desorbed-steam input pipeline, a benzene-containing steam discharging pipeline, a condensation cooler, an oil-water separating groove and a benzene storage groove, wherein the tail-gas fan is used for introducing benzene-containing tail gas escaping from a truck opening in the benzene-hydrogenation process into the N absorbing tanks; all benzene-containing tail gas feeding holes of the N absorbing tanks are respectively connected with an outlet of the tail-gas fan and are internally and respectively provided with an absorbing agent; the purified-gas discharging pipeline is connected with purified-gas discharging holes of the N absorbing tanks; the desorbing-steam input pipeline is connected with desorbing-steam feeding holes of the N absorbing tanks; the benzene-containing steam discharging pipeline is connected with benzene-containing steam discharging holes of the N absorbing tanks; an inlet of the condensation cooler is connected with an outlet of the benzene-containing steam discharging pipeline; the oil-water separating groove is connected with an outlet of the condensation cooler; the benzene storage groove is connected with an oil outlet of the oil-water separating groove. The device disclosed by the invention is simple in structure, convenient in modification and installation, convenient in adjustment, good in purifying effect, high in recovery efficiency and low in cost.

Owner:山东莱钢环友化工能源有限公司

Method and apparatus for purifying polycrystalline silicon through rotation and blow induced inversion solidification

Owner:DALIAN UNIV OF TECH QINGDAO NEW ENERGY MATERIALS TECH RES INST CO LTD

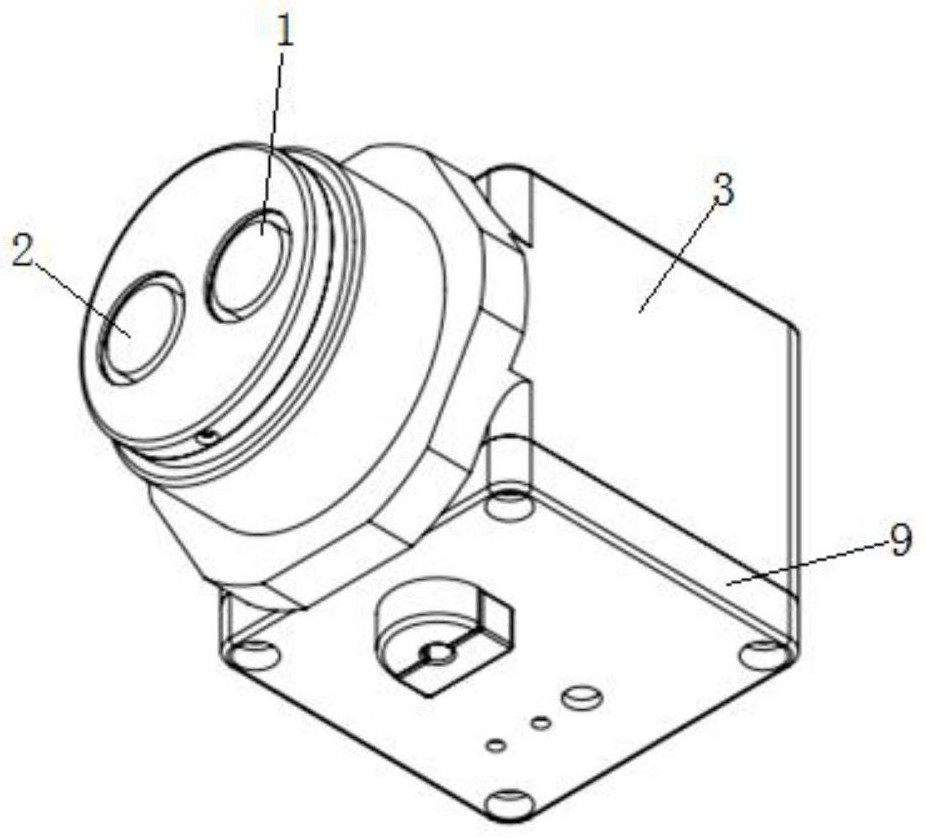

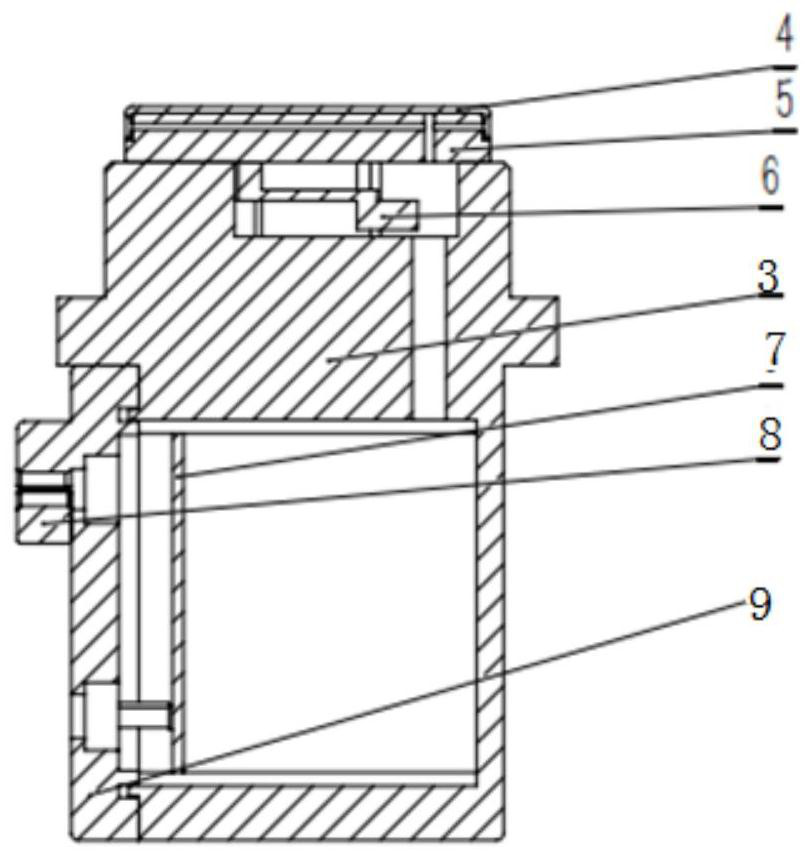

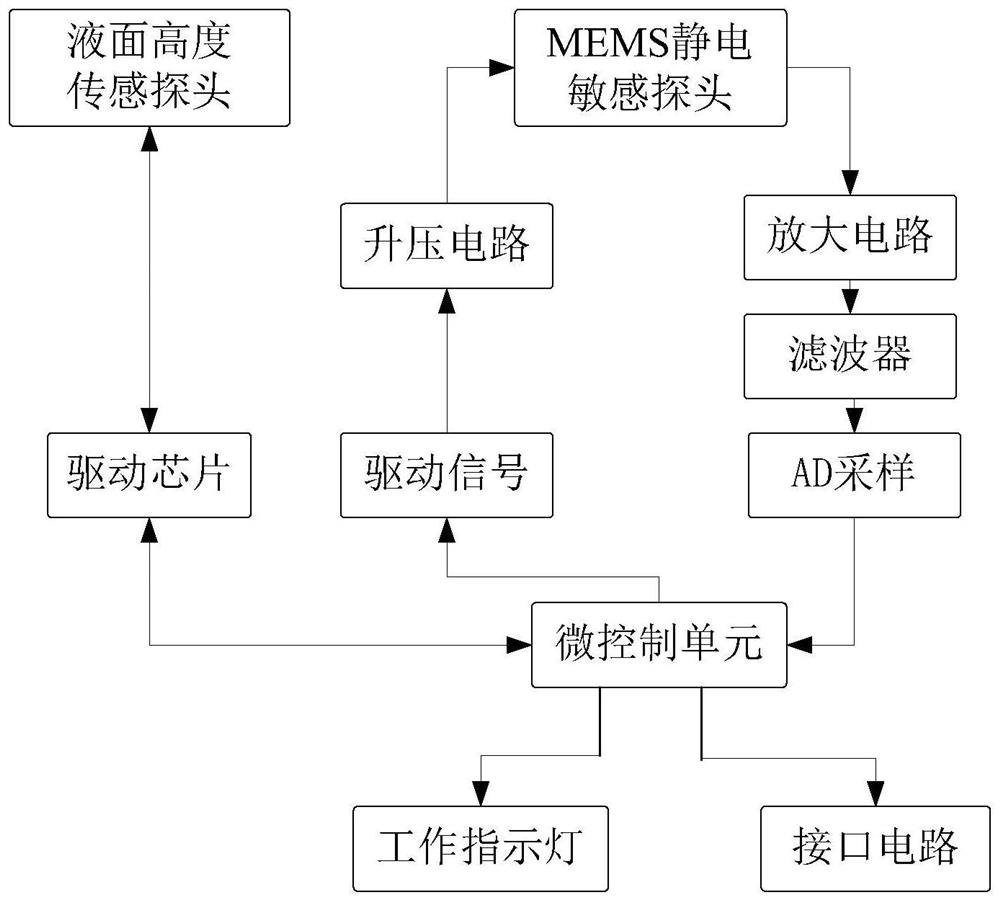

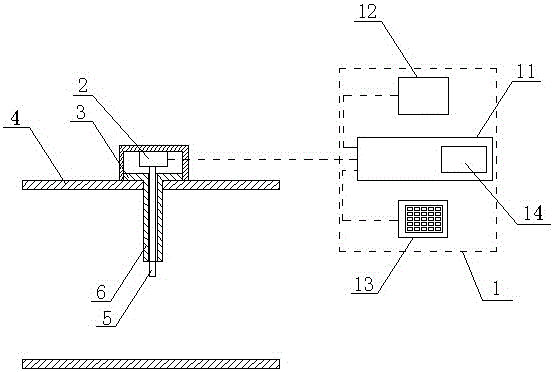

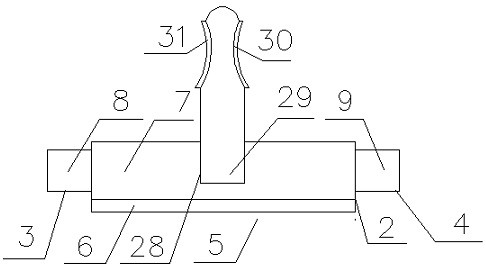

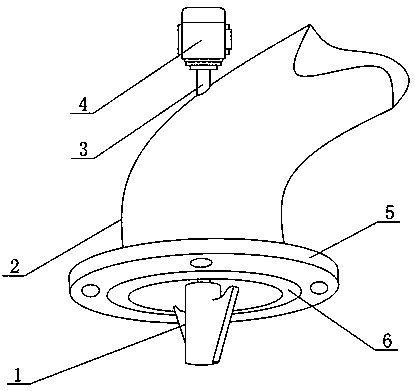

Safety type liquid level height and liquid level potential comprehensive testing device

InactiveCN112113599AHigh precision measurementLow costMeasurement devicesLarge containersCombined testLiquid state

The invention discloses a safety type liquid level height and liquid level potential comprehensive testing device, and particularly relates to the field of electrostatic safety protection in the storage, transportation, loading and unloading processes of petrochemical engineering liquid materials. The safety type liquid level height and liquid level potential comprehensive testing device comprisesa shell, an upper cover; an electrostatic sensitive probe unit and a liquid level height sensing probe unit are arranged on the shell, the electrostatic sensitive probe unit can be a non-contact micro electro mechanical system (MEMS) electrostatic sensitive probe unit, and a signal processing and control unit is arranged in the shell. The electrostatic sensitive probe unit and the liquid level height sensing probe unit are in electric control connection with the signal processing and control unit. The shell comprises a square body, a cylindrical head extends out of one end face of the squarebody, the signal processing and control unit is located in the square body, and the electrostatic sensitive probe unit and the liquid level height sensing probe unit are located on the head. The tailend of the head is provided with a thread at one end, and when the device works, the head is screwed on a storage tank through a thread to be connected with the storage tank.

Owner:CHINA PETROLEUM & CHEM CORP +1

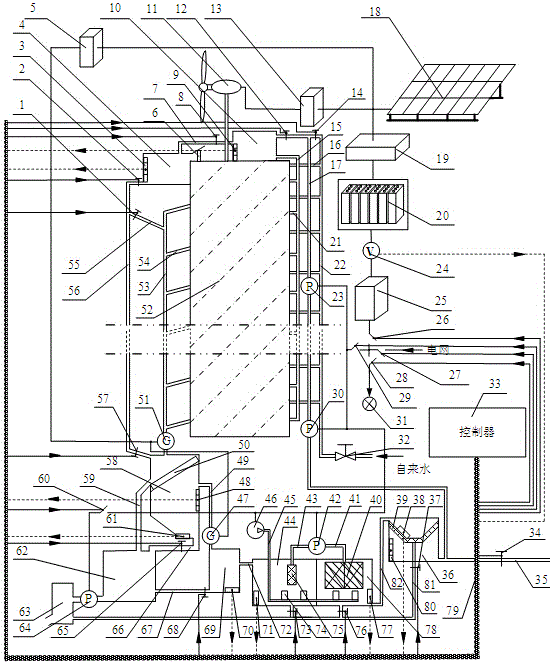

High-rise building domestic sewage green purification and reuse system and control method thereof

InactiveCN105668919ASimple structureEasy to retrofit and installBatteries circuit arrangementsPV power plantsStormwaterSewage

The invention provides a high-rise building domestic sewage green purification and reuse system and a control method thereof. The system comprises: a rainwater-sewage power generation unit, a wind-solar complementary power generation unit, a storage battery power supply unit, a sewage disposal-sewage purification unit, a purified water reuse unit and a control unit. The system not only can fully utilize the characteristics of high-rise buildings, comprehensively utilizes wind energy, solar energy, rainwater and domestic sewage's mechanical energy, but also applies the green energy to a domestic sewage purification and reuse system, realizes purification and reuse of high-rise building domestic sewage, and maximumly recovers and utilizes various energy of high-rise buildings. With a simple structure, the system provided by the invention is convenient for transformation and installation of existing high-rise buildings, and also can effectively improve urban environment.

Owner:XUZHOU NORMAL UNIVERSITY

Vibrating sieving machine with muting box

The invention discloses a vibrating sieving machine with a muting box. The vibrating sieving machine comprises the muting box and a vibrating sieving machine main machine mounted in the muting box, wherein the muting box comprises a base and two sound insulation half box bodies, the two sound insulation half box bodies are symmetrically mounted on the top of the base left and right, the front sides of the two sound insulation half box bodies are connected through a lock catch, a fixing column is vertically arranged on the part, located at the joint between the two sound insulation half box bodies, of the top of the rear side of the base, the bottom of the fixing column is fixedly connected with the top of the rear side of the base, the rear sides of the two sound insulation half box bodiesare hinged to the fixing column through a plurality of hinges, one sides of the hinges are fixedly connected with the outer side of the fixing column, and the other sides of the hinges are fixedly connected with the inner walls of the rear sides of the sound insulation half box bodies; and sealing strips are arranged between the bottom of the sound insulation half box bodies and the base, betweenthe front sides of the two sound insulation half box bodies, between the rear sides of the two sound insulation half box bodies, and between the top sides of the two sound insulation half box bodiescorrespondingly. According to the vibrating sieving machine, the muting box is arranged so that noise generated during operation of the vibrating sieving machine can be greatly reduced, and the assembly and the disassembly are convenient.

Owner:XIAN UNIV OF SCI & TECH

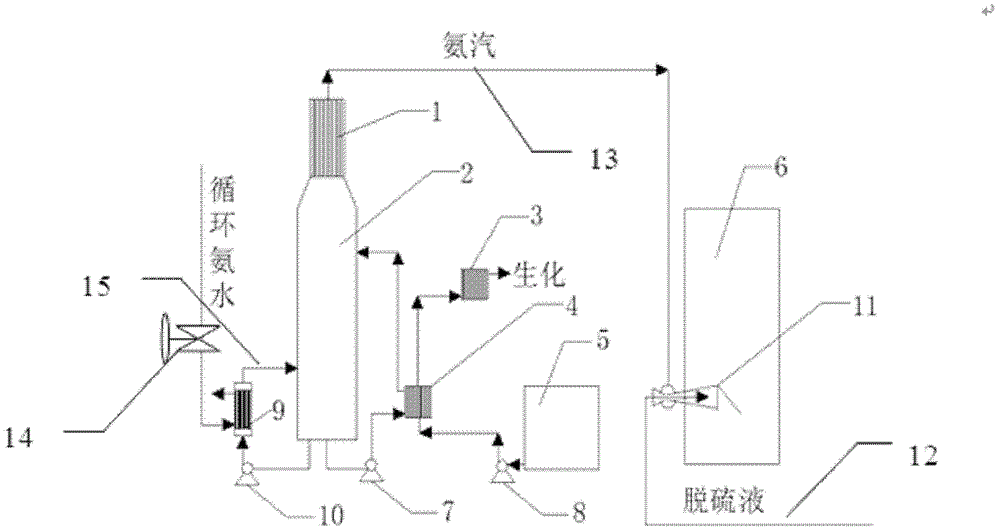

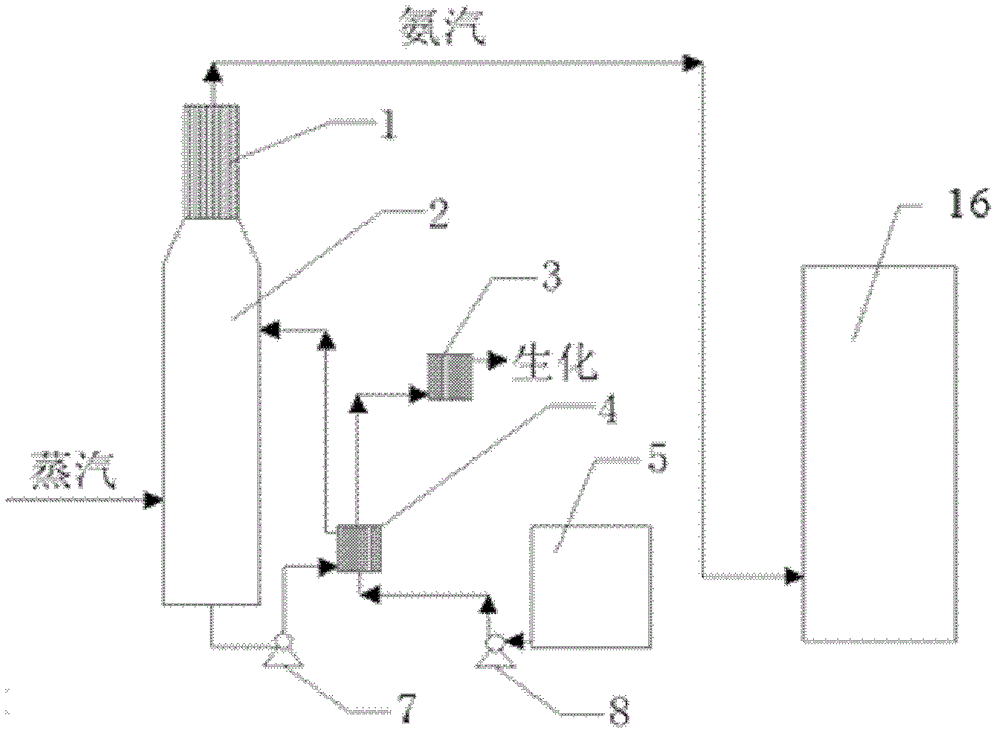

Negative pressure ammonia distillation process and device for residual ammonia water in coking production

ActiveCN102351265BSimple structureEasy to retrofit and installWater/sewage treatment by degassingThermodynamicsWastewater

The invention relates to a negative pressure ammonia distillation process and a negative pressure ammonia distillation device for residual ammonia water in coking production. A venturi tube is arranged at the ammonia steam inlet of a desulfurizing tower; and the bottom of an ammonia distillation tower is provided with an ammonia distillation wastewater / circulating ammonia water heat exchanger andan ammonia distillation wastewater circulating pump. The ammonia distillation wastewater / circulating ammonia water heat exchanger and the ammonia distillation wastewater circulating pump are started,so that heat of circulating ammonia water is brought in the ammonia distillation tower by ammonia distillation wastewater; when the temperature of the top of the ammonia distillation tower is between60 and 80 DEG C, a desulfurizing solution pipeline valve of the venturi tube is opened, and ammonia steam is sucked into the desulfurizing tower; meanwhile, a residual ammonia water pump and an ammonia distillation wastewater pump are started, the residual ammonia water enters the ammonia distillation tower through the heat exchanger, and the ammonia distillation wastewater at the bottom of the tower flows through the heat exchanger and an ammonia distillation wastewater cooler and is subjected to biochemical treatment. The process is simple, equipment has a reasonable structure and is convenient to install and adjust, energy consumption can be effectively reduced, and the ammonia distillation wastewater index is stabilized.

Owner:SHANDONG IRON & STEEL CO LTD

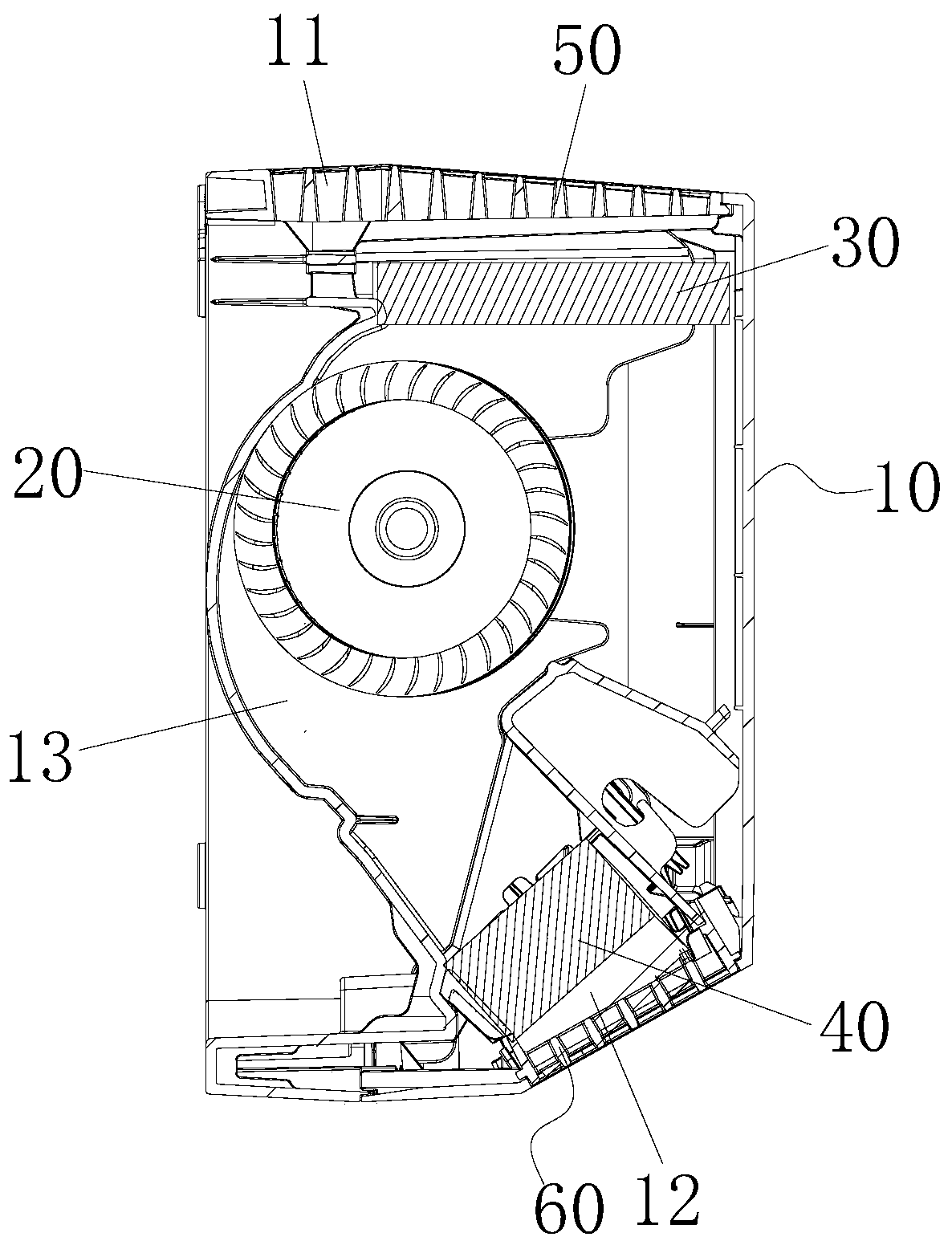

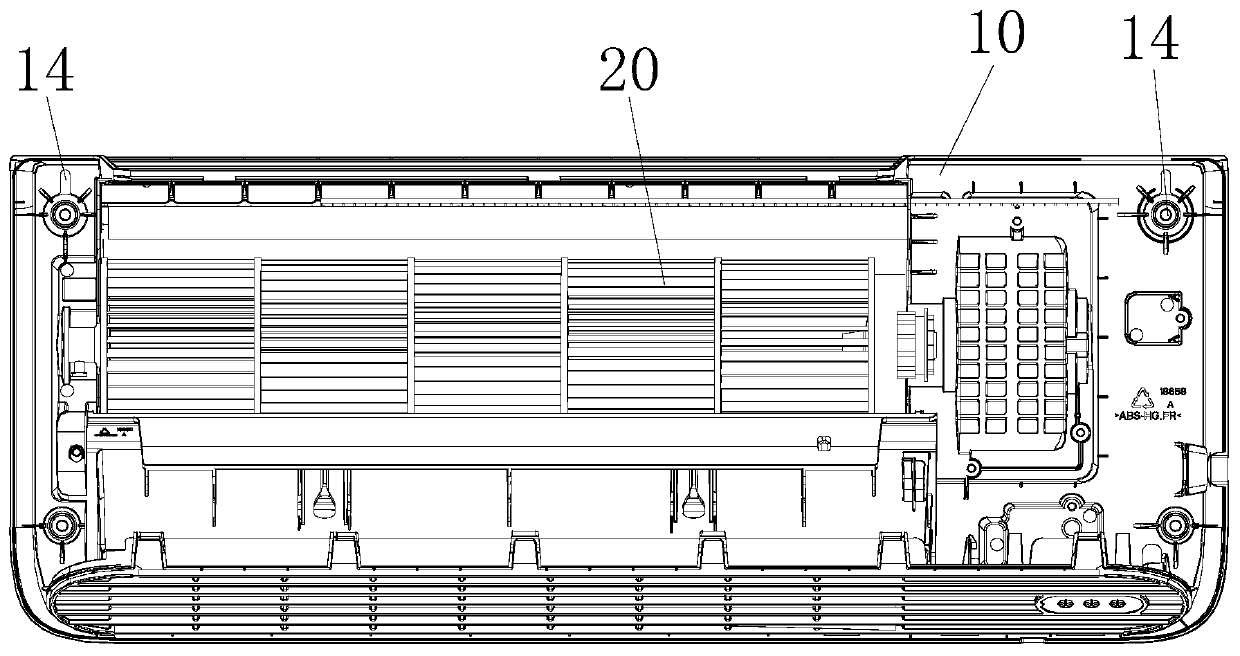

Wall-mounted disinfection equipment

PendingCN111442433AEasy to retrofit and installTo achieve the purpose of disinfectionDucting arrangementsMechanical apparatusEngineeringEnvironmental engineering

The invention discloses wall-mounted disinfection equipment. The comprises a wall-mounted shell which is provided with an air inlet and an air outlet, a fan, a negative ion generator and a disinfecting device; an air channel is formed in the wall-mounted shell; the air channel communicates with each of the air inlet and the air outlet; the fan is mounted in the wall-mounted shell and is positionedin the air channel; the negative ion generator is mounted at the air inlet; and the disinfecting device is mounted at the air outlet. The wall-mounted disinfection equipment disclosed by the invention provides the equipment which performs disinfection with regard to elevator closed air.

Owner:GREE ELECTRIC APPLIANCES ZHONGSHAN SMALL HOUSEHOLD APPLIANCES MFG +1

Product recognition exclusive system and method

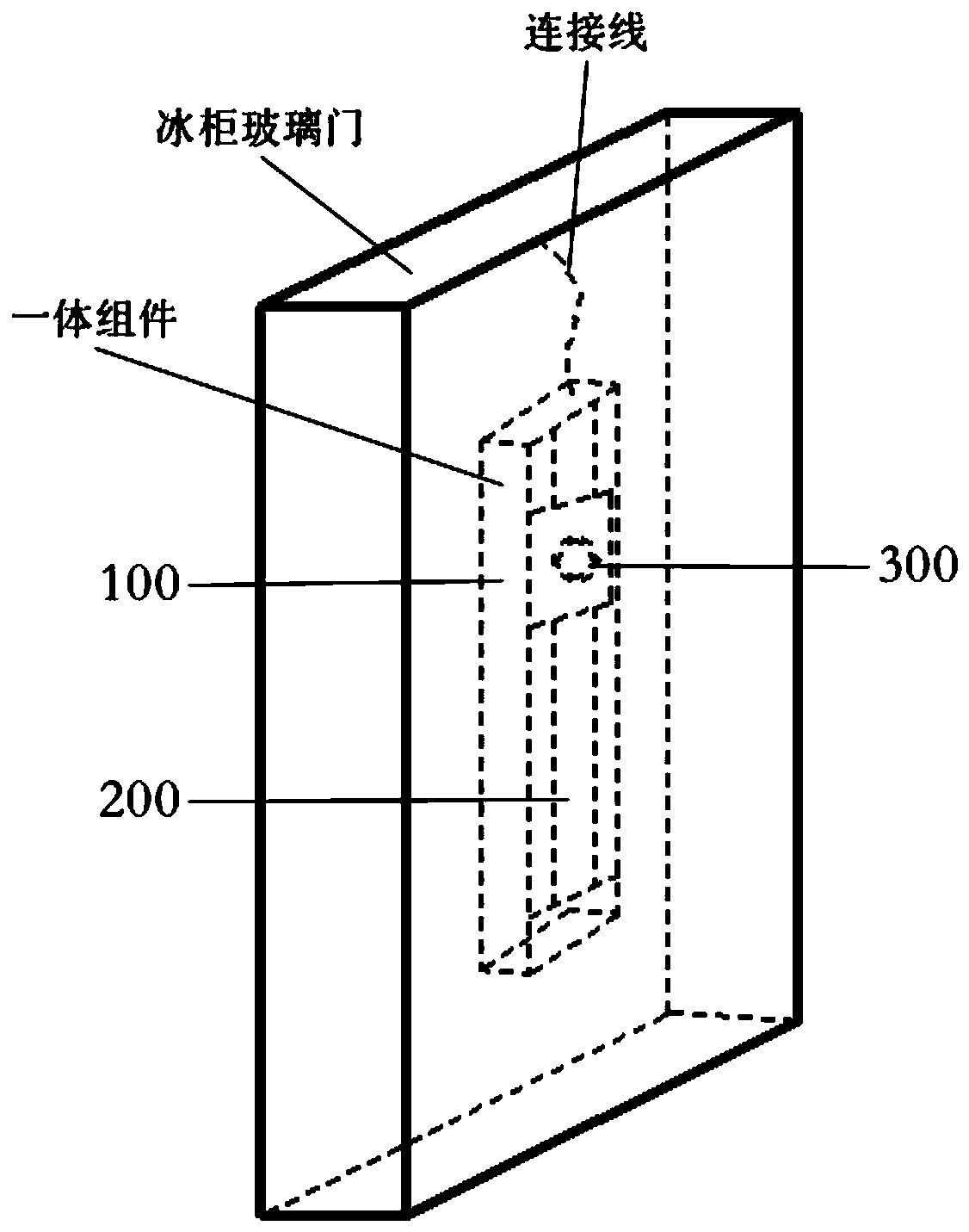

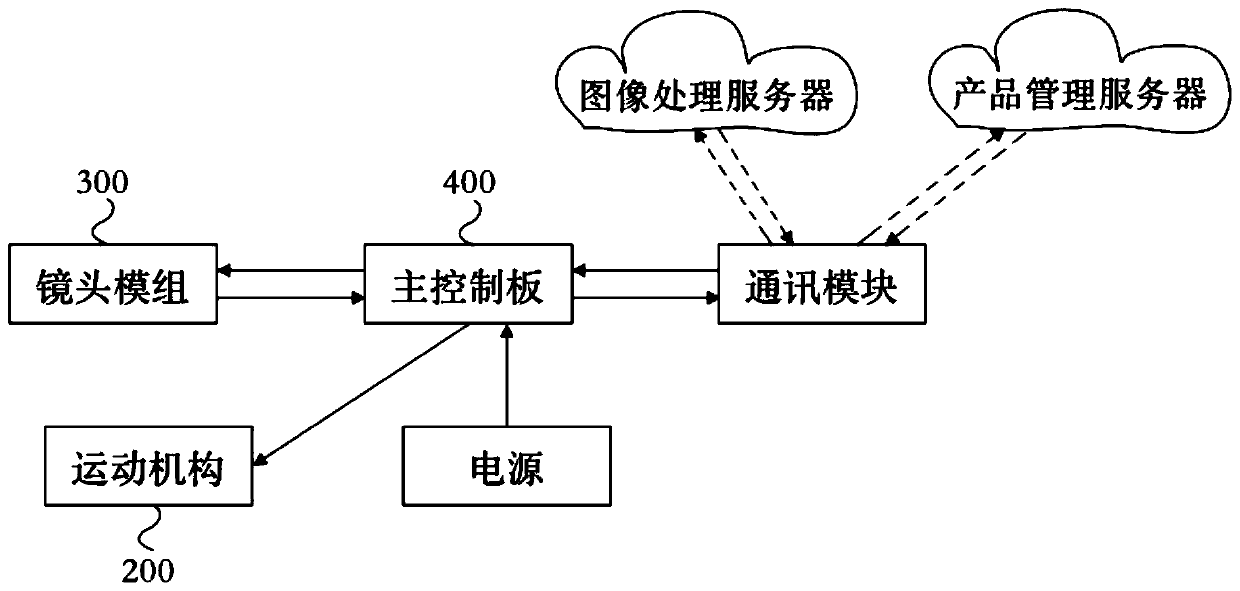

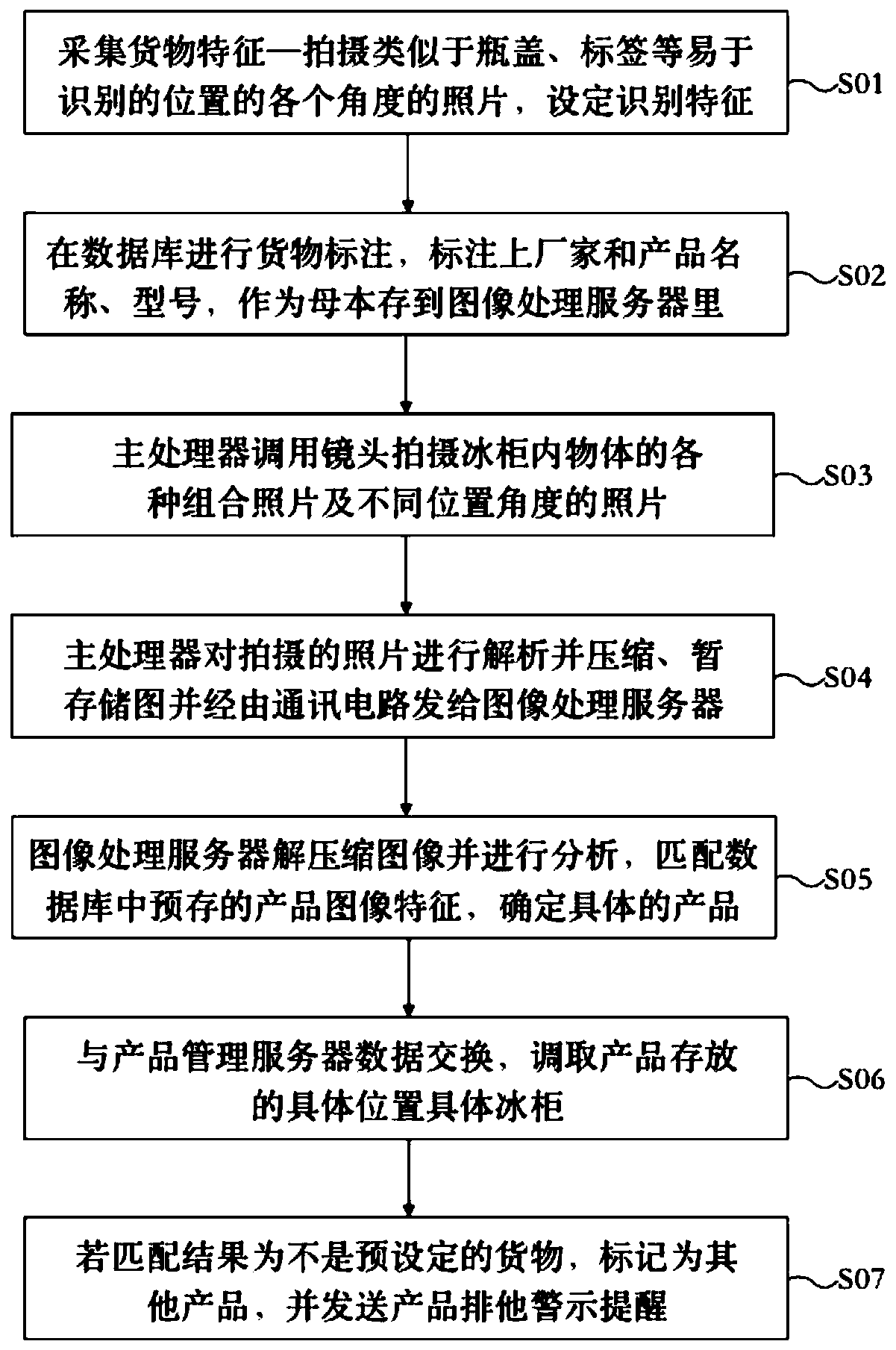

PendingCN111598590ASimple way of workingExquisite structure designCommerceImaging processingIndustrial engineering

The invention discloses a product recognition exclusive system and method. The invention relates to a refrigerator door body movement mechanism which comprises an integrated assembly, the integrated assembly is formed by a plastic shell wrapping the movement mechanism and a lens module in a sealed mode, the integrated assembly is installed in the middle of double-layer glass of a refrigerator doorbody, and the integrated assembly can be installed vertically, transversely and obliquely so as to achieve better recognition of products. The integrated assembly comprises a main control board, anda connecting wire extends out of the integrated assembly and is electrically connected with the main control board; the image processing module comprises an image processing server and is used for receiving the images shot by the lens module, analyzing the images, recognizing the characteristics of the stored products, calculating the quantity, comparing the set products in the database and givinga matching result feedback alarm; the system comprises a product management server for managing product storage equipment. The product recognition exclusive system is simple and exquisite in structural design, low in manufacturing cost, easy to install and high in recognition success rate.

Owner:青岛文潮电子有限公司

Gravity-flow type efflux technology of condensate of coal gas primary cooler

InactiveCN101698806BEasy to operateAvoid pollutionGas purification by non-gaseous materials condensationHeight differenceGravity flow

Owner:SHANDONG IRON & STEEL CO LTD

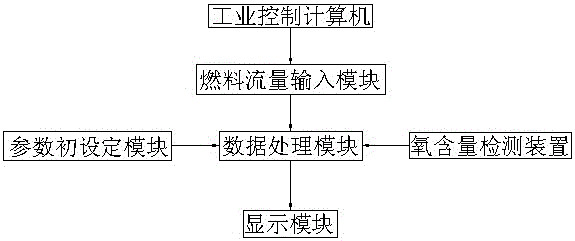

Plug-in flue gas flow measurement method and measurement device based on detection of oxygen content

ActiveCN103292842BAccurate measurementEasy to retrofit and installVolume/mass flow measurementFlue gasProcess engineering

Owner:BAOSHAN IRON & STEEL CO LTD +1

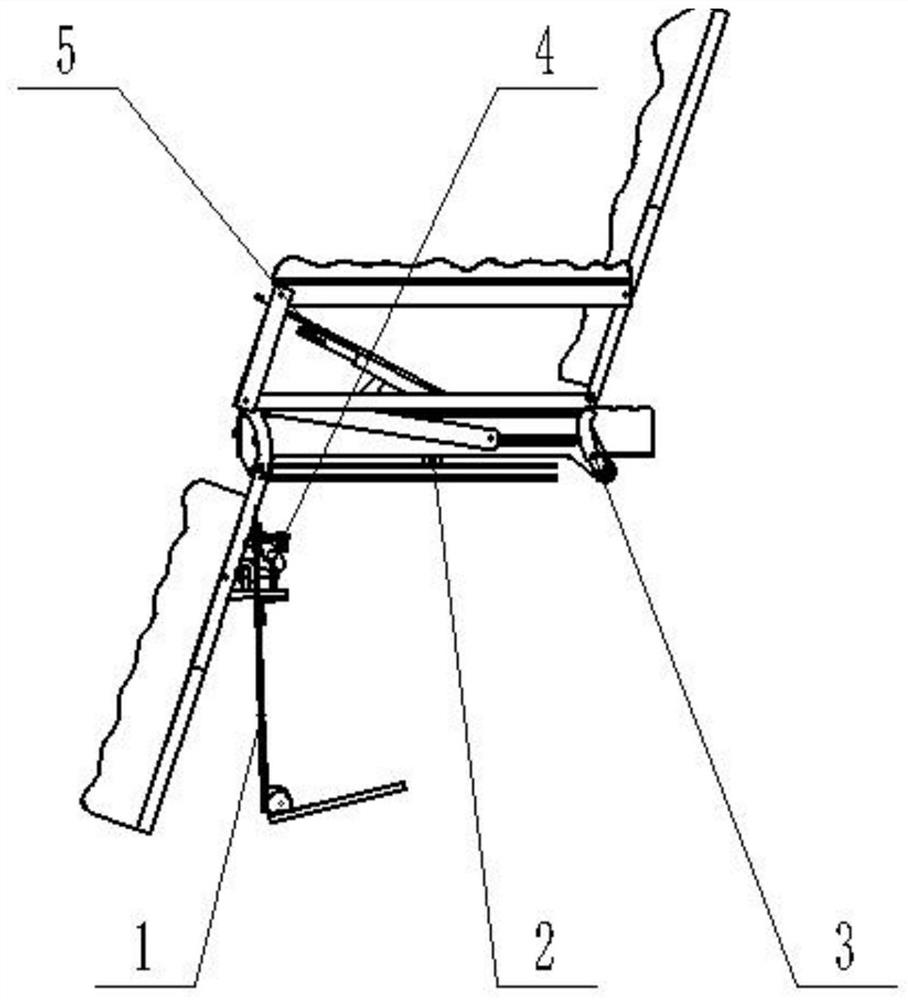

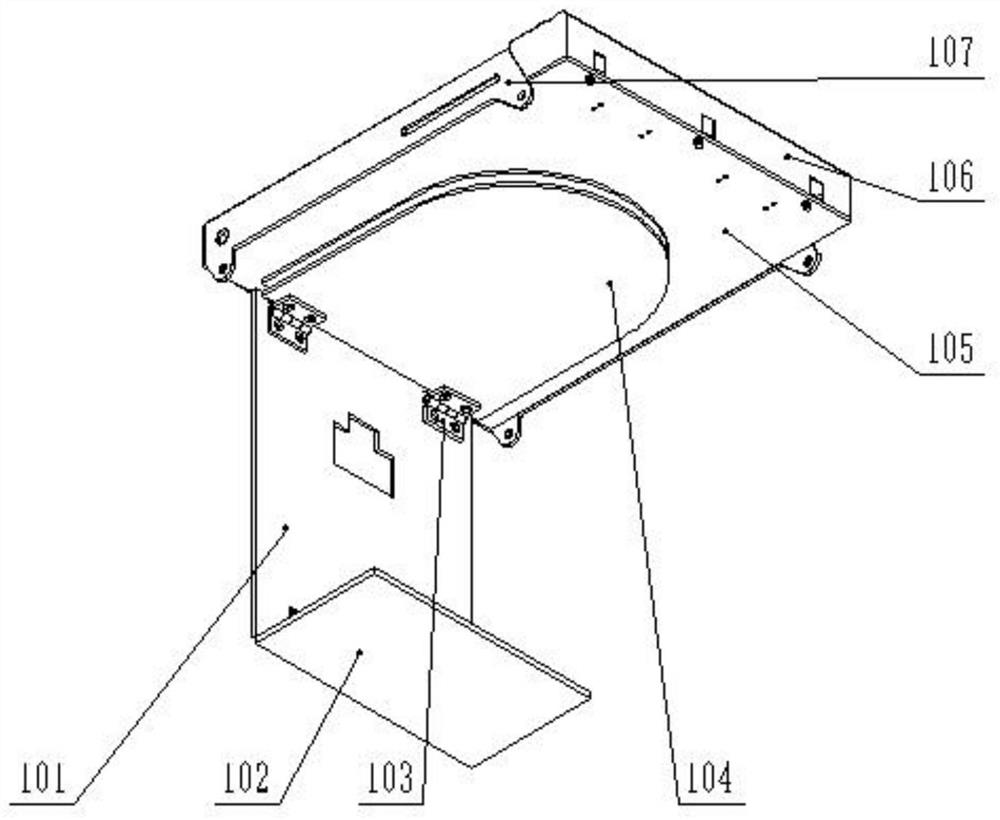

Mechanical device for assisting the elderly to get up and down

The invention provides a mechanical device for assisting old people to get up and down. The device includes a bed frame, a driving mechanism, a transmission mechanism, a leg plate one-way locking mechanism and a supporting rod resetting mechanism, and the bed frame includes a vertical plate, a floor plate, a bottom plate, a bed seat and a steering bearing; and the floor plate is connected with thevertical plate, the bottom plate is connected with the second end part of the vertical plate to form a bed body connection part, and the bed body connection part can be connected with an external bedbody. The driving mechanism is a power source of the device and adopts a turbine worm rod structure, and motor steering is controlled to control worm rod steering to realize the entire process of turning of a bed body and standing up and flat lying; the transmission mechanism uses a four-bar mechanism; the leg plate one-way locking mechanism uses meshing of a first one-way bearing, a cam, a gearand a rack to realize locking, and the rack moves under the action of motors to realize hooking and loosening of a hook; and in the mechanical stretching and lifting process of the supporting rod resetting mechanism, a seat plate can be always kept in a horizontal state to hold people to lift the people up.

Owner:YANSHAN UNIV

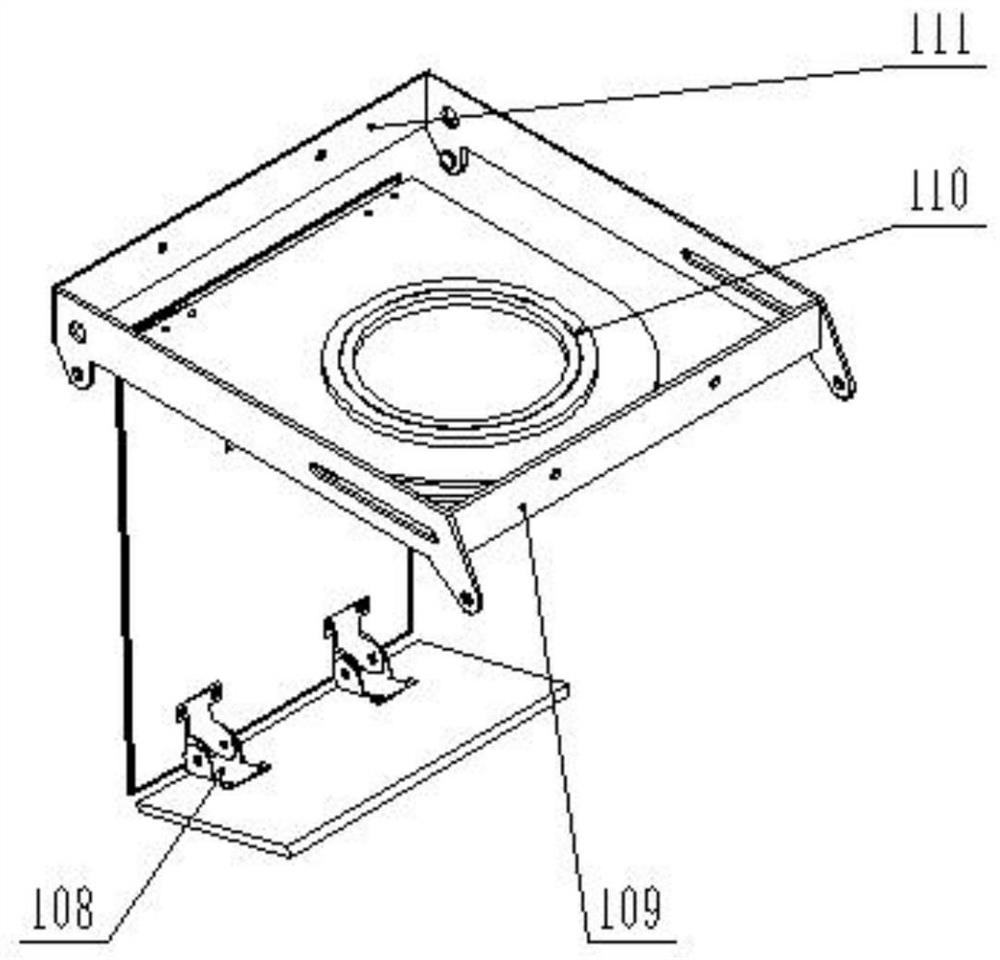

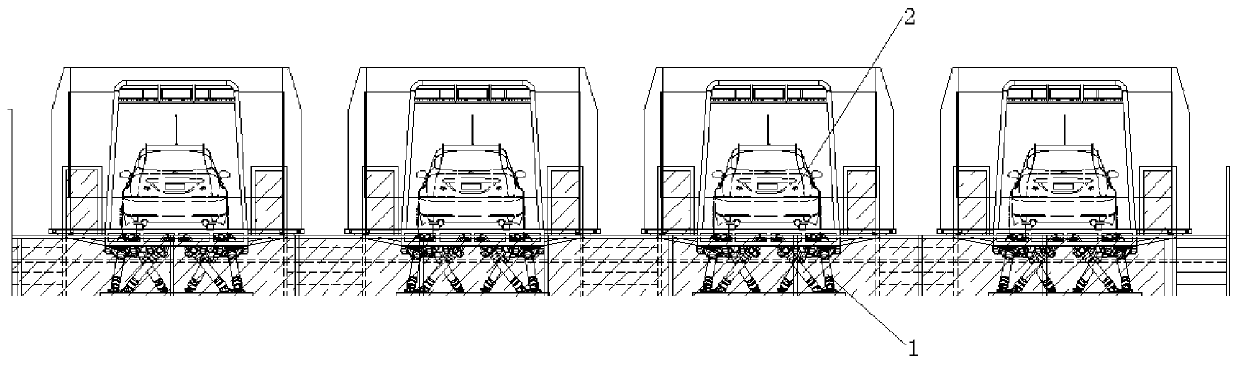

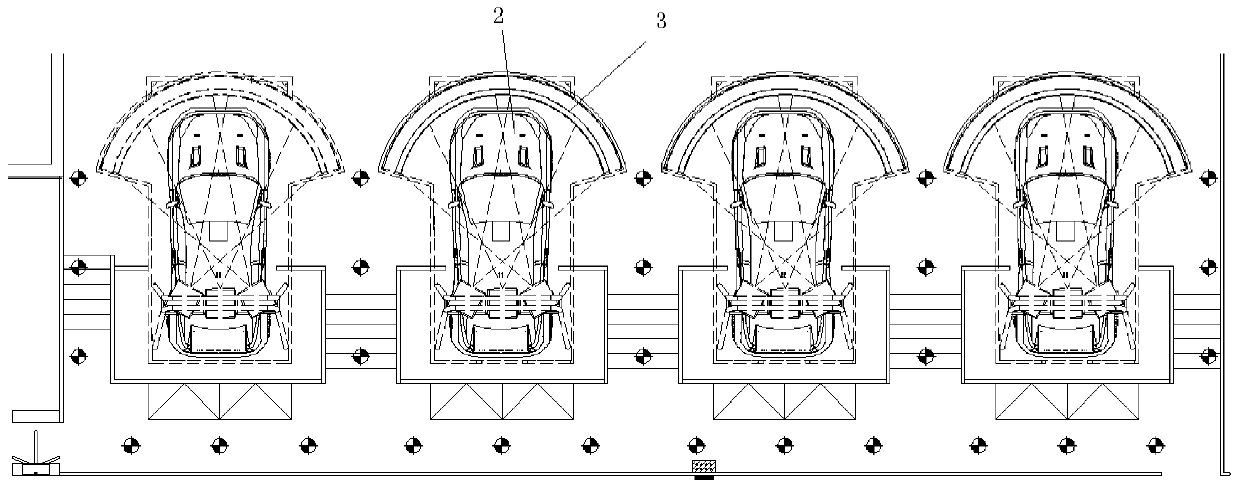

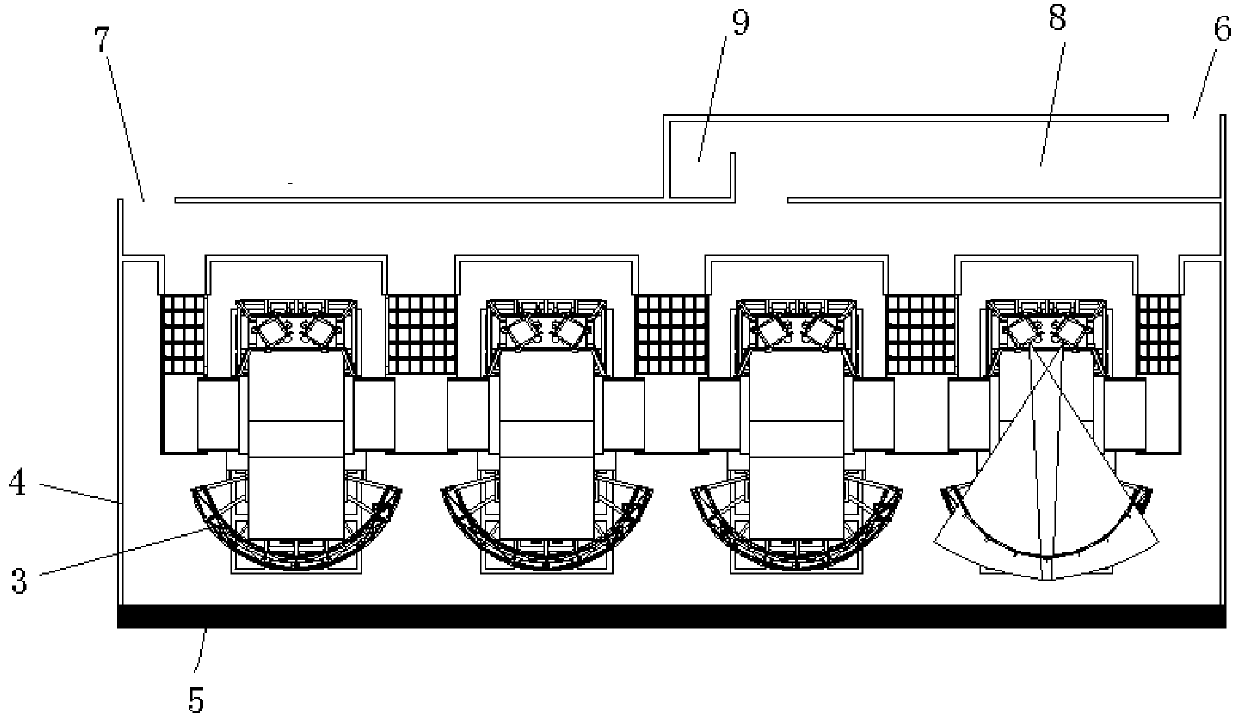

Simulated driving system

The invention provides a simulated driving system. The simulated driving system comprises at least one multi-degree of freedom platform, passenger carriers, a display device and a control system, wherein the passenger carriers are fixedly arranged on the multi-degree of freedom platforms, each multi-degree of freedom platform is correspondingly provided with one passenger carrier, and a manipulating device is arranged in each passenger carrier and at least comprises a steering wheel, an accelerator and a brake; the display device is arranged at the front side of the passenger carriers and usedfor displaying road conditions of a simulated track; and the control system is electrically connected with the multi-degree of freedom platforms, the manipulating device and the display device respectively. When a user controls a certain manipulating device, movement parameters of the corresponding steering wheel, accelerator and brake can be fed back to the control system, the control system controls the corresponding multi-degree of freedom platform to match corresponding data according to the movement parameters of the corresponding steering wheel, accelerator and brake and controls the corresponding multi-degree of freedom platform to generate corresponding actions, so that the user has a true driving feeling; and meanwhile, the display device displays the road conditions of the simulated track, so that the user has a true competition-participating feeling, and the entertainment is strong.

Owner:DALIAN WANDA GROUP CO LTD

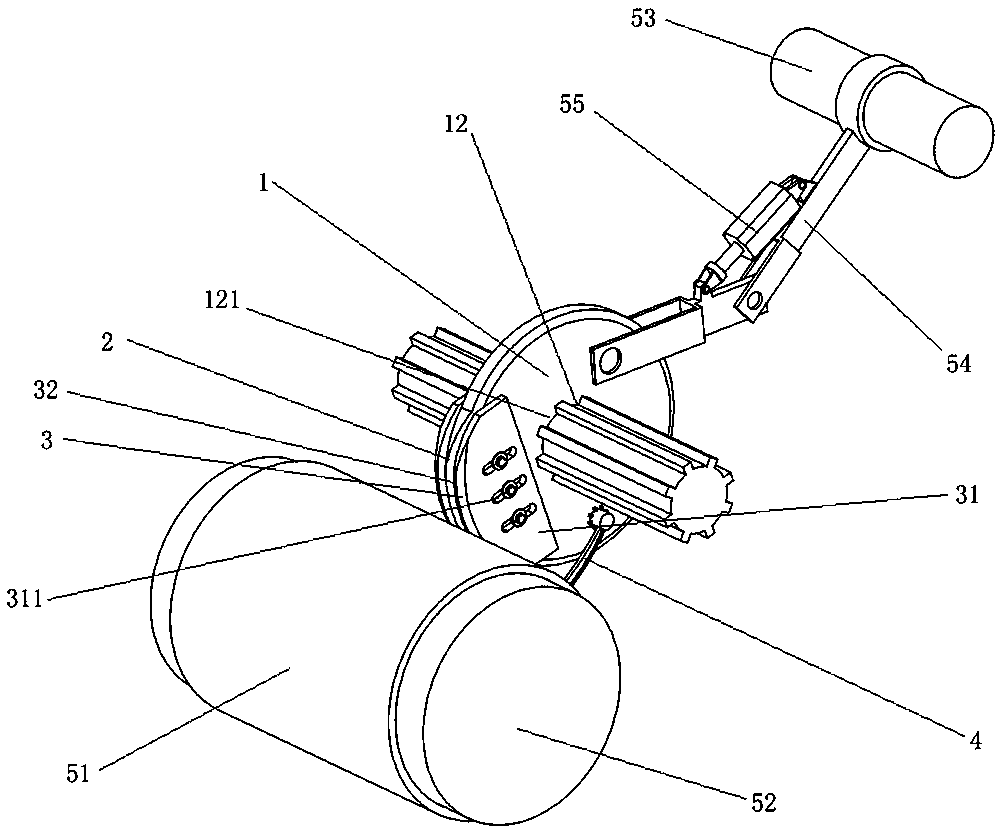

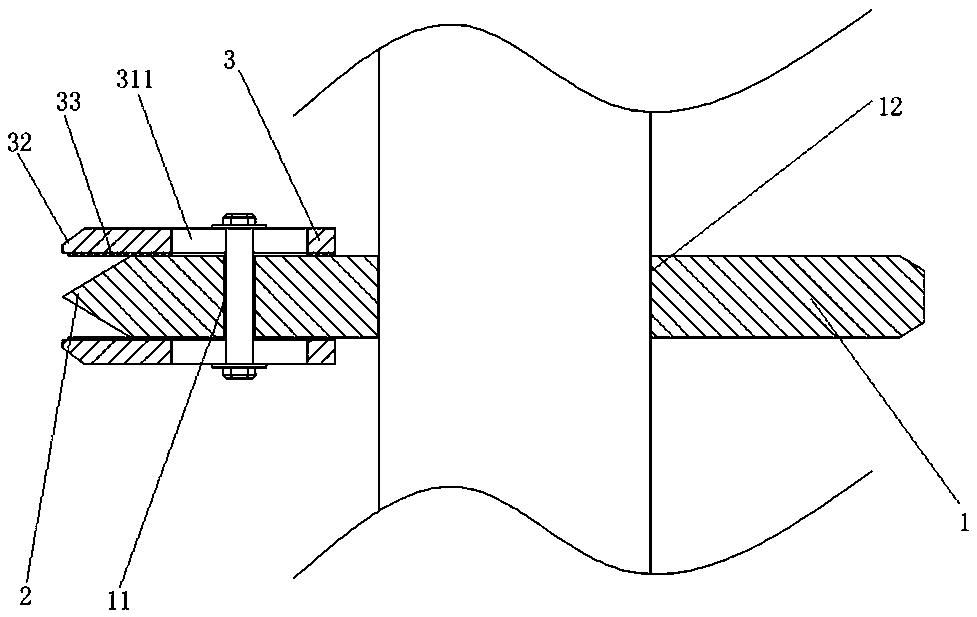

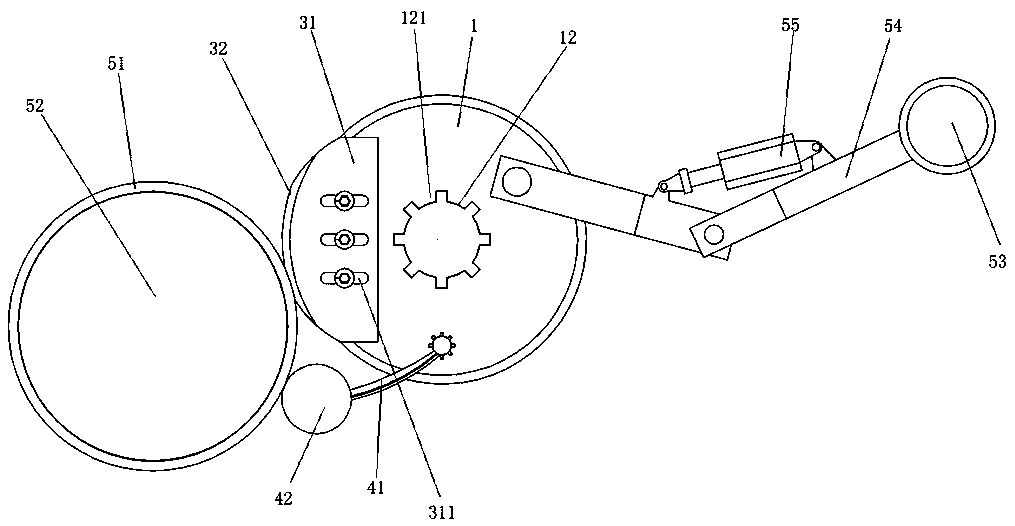

Brake locking device and method of use of beam pumping unit

InactiveCN110195749BImprove braking effectEasy to retrofit and installConstructionsFluid removalReduction driveStructural engineering

Owner:宋晶鑫 +2

Indenting and grooving integrated blade

PendingCN108943087ASimple structureLow manufacturing costMetal working apparatusEngineeringCircular segment

Owner:ZHEJIANG HUANLONG MACHINERY CO LTD

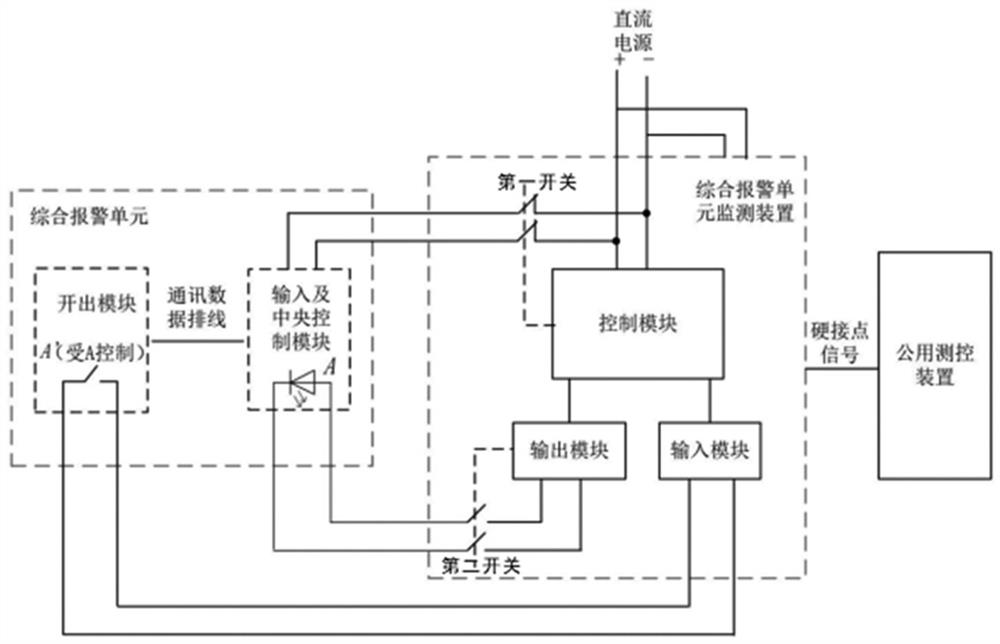

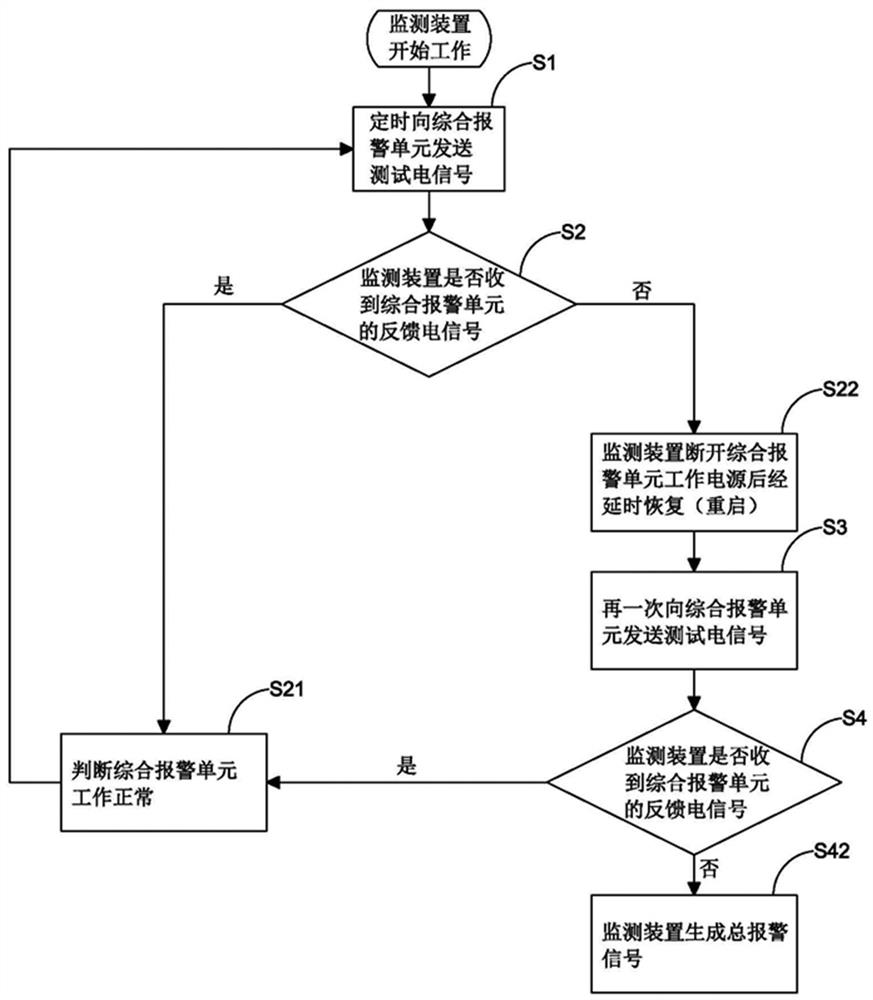

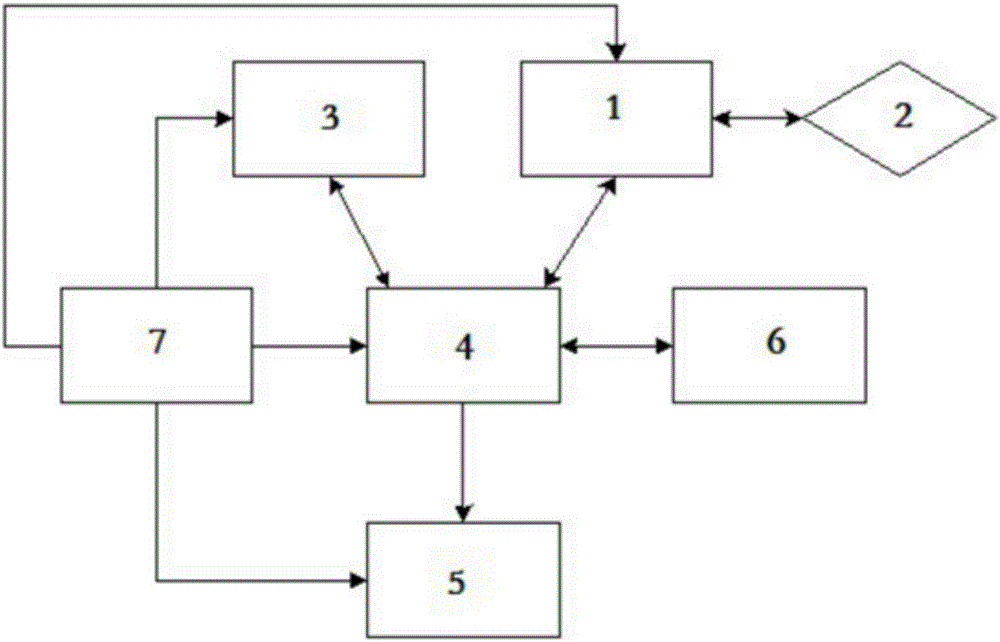

An online monitoring device and method for a comprehensive alarm unit of substation GIS equipment

ActiveCN113253038BEasy to retrofit and installSimple processElectrical testingElectric signalPower substation

This application belongs to the technical field of substations, and provides an online monitoring device and method for a comprehensive alarm unit of GIS equipment in a substation. The device includes: a control module, an output module, an input module and a power supply module. The output module sends a test electrical signal to the monitored integrated alarm unit. If the control module receives the feedback electrical signal through the input module, it considers that the integrated alarm unit is working normally; Alarm. According to the state of the electric signal, the application can realize online monitoring whether the operation of the comprehensive alarm unit is abnormal, and it is convenient to directly modify and install the stock comprehensive alarm unit; the monitoring device can be fixed by screws and simple buckle wiring can be completed The installation in the GIS equipment control cabinet is simple.

Owner:ZHONGSHAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID

Inter-vehicle driving condition communication device

The invention relates to an inter-vehicle driving condition communication device, which comprises a central control module, a communication module, a positioning module, a power supply module, a display module, a vehicle-mounted computer and an antenna. The communication module, the positioning module, the power supply module, the display module and the vehicle-mounted computer are respectively connected with the central control module. The communication module, the positioning module and the display module are respectively connected with the power supply module. The communication module is connected with the antenna. The device is simple in design and low in cost, which can be conveniently transformed and installed on an existing vehicle. By means of the device, the correction rate of a driver in judging the driving condition information of other vehicles on the road can be effectively improved, so that the misjudgment of the driver or the time-free reaction of the driver can be avoided. When necessary, the driver can take necessary intervention measures for the vehicle driving condition. Therefore, the misoperation of the driver or the accidents of vehicles can be avoided.

Owner:邓春生

Method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing by quartz tube

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing by a quartz tube. According to the method, under inert gas environment, silicon is melt and then is cooled to pull ingot; when solidification is completed by 85-90%, the quartz tube is stretched into the surplus melt silicon, vacuumizing is stopped, inert gas is led in, the surplus melt silicon enters the quartz tube under the action of pressure difference, ingot pulling is continuously carried out, after the upper end of a crucible leaves a heating area, a tailing collection box is stretched below the quartz tube with a point; the power is cut off so as to stop heating, melt silicon in the quartz tube expands, then the quartz tube cracks and falls into the tailing collection box, and cast ingot of high purity in the crucible is obtained. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, is simple to operate, can effectively remove impurities accumulated at the tail of the cast ingot, save production period and cost, and is applicable to industrial production.

Owner:QINGDAO NEW ENERGY SOLUTIONS

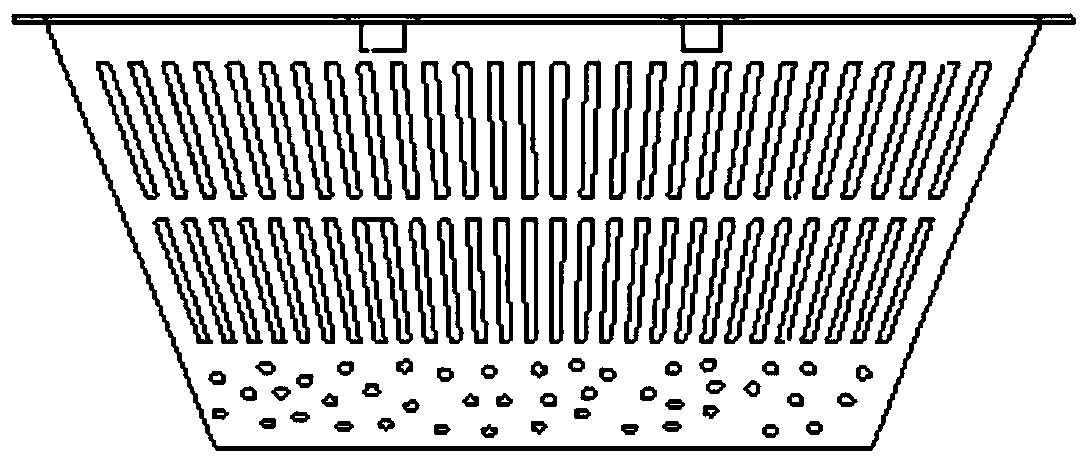

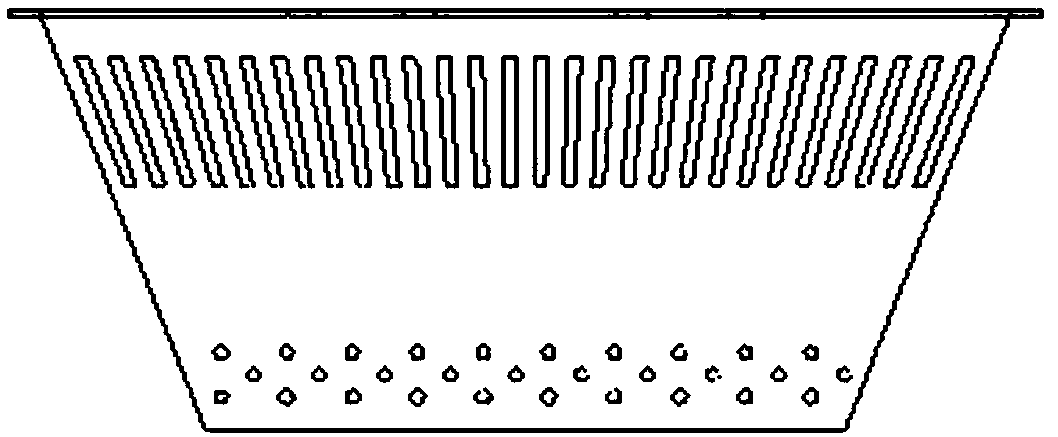

Common sewage-interception hanging basket and mounting method

PendingCN109469192AEasy to retrofit and installSignificant ecological and environmental benefits and promotion and application valueFatty/oily/floating substances removal devicesSewerage structuresSolid suspensionEngineering

The invention discloses a common sewage-interception hanging basket and a mounting method. The common sewage-interception hanging basket comprises a sewage-interception hanging basket body, a rectangular opening is formed in the top of the sewage-interception hanging basket body, and a long edge of one side of the rectangular opening corresponds to a long edge curved surface side wall; a long edgeof the other side corresponds to a long edge plane side wall, and the side walls, corresponding to the two short edge sides, of the rectangular opening are short edge plane side walls; the bottoms ofthe long edge curved surface side wall, the long edge plane side wall and the short edge plane side walls are connected to a basket bottom; vertical drainage holes are formed in the long edge plane side wall and the short edge plane side wall, no hole is formed in the middle of the long edge plane side wall, and a vertical drainage hole is formed in the upper portion of the long edge plane side wall; a water draining hole is formed below each drainage hole. According to the hanging basket, the rainfall runoff impurities can be effectively intercepted, and the large-grain-size solid suspensionsubstances are precipitated; a buckle device and a plug device are arranged at the outer edge of the top of the sewage-interception hanging basket, and the sewage-interception hanging basket can be conveniently fixed to the lower portion of a rainwater grate and is convenient to detach, clean and maintain and suitable for all types of rainwater ports.

Owner:BEIJING WATER SCI & TECH INST

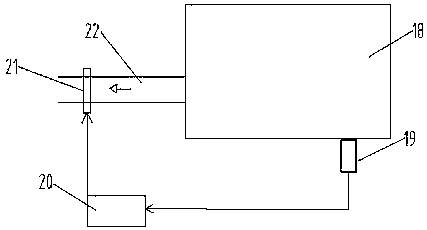

Equipment for automatically controlling pressure of glass kiln

PendingCN110272183AEasy to openEasy to retrofit and installGlass furnace apparatusAutomatic controlFlue gas

The invention relates to equipment for automatically controlling the pressure of a glass kiln. The equipment comprises a gate device (21), the gate device (21) is installed at a flue gas outlet (22) of the glass kiln (18), and a pressure transmitter (19) is installed on a glass kiln (18) and connected with a PLC (20) through a signal line; the PLC (20) is connected with a locator (3) through a control signal connection line (17), the locator (3) receives a control signal and then controls a cylinder telescopic rod (16) to rise and fall, then a gate (9) is driven by a steel wire rope (5) to rise and fall vertically, and the height and size of gate opening can effectively control the pressure in the glass kiln. According to the device, automatic control is conducted according to the kiln pressure of the glass product kiln, and the product quality is effectively ensured.

Owner:云南旺焱玻璃包装制品有限责任公司

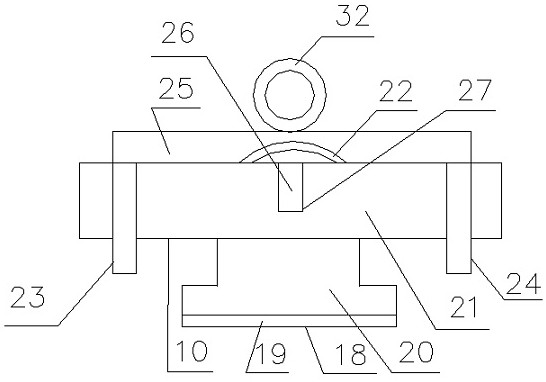

Discharge pipe distributing mechanism for powder mixer

InactiveCN103418304ASimple structureEasy to retrofit and installMixer accessoriesElectric machineryEngineering

The invention discloses a discharge pipe distributing mechanism for a powder mixer. The discharge pipe distributing mechanism comprises a discharge pipe (2) and a distributing mechanism body. The distributing mechanism body comprises a distributing head (1) with at least two inverted-triangle-shaped fins evenly distributed on the lateral sides, a transmission shaft (3) and a motor (4). The distributing head (1) is located at the center of a discharge outlet of the discharge pipe. One end of the distributing head (1) is fixedly connected with the transmission shaft (3). The other end of the transmission shaft (3) is fixedly connected with a rotary shaft of the motor (4). By the discharge pipe distributing mechanism, powder can evenly distribute over the whole hopper favorably without human interference. The amount of power, passing the rotating area of the distributing head, which is in contact with the fins is reduced by the fins, and part of the powder can drop right below the distributing head. In addition, the discharge pipe distributing mechanism is simple in structure and easy to mount and modify on existing equipment.

Owner:CHENGDU XILI INVESTMENT

Slag fetching device used after slagging smelting and use method thereof

Belonging to the technical field of metallurgical slagging, the invention in particular relates to a slag fetching device used after slagging smelting and a use method thereof. On the basis of original slagging equipment, a slag storer, a graphite pipe and a vacuum instrument are added. The use method includes: firstly heating a silicon material and slag to a molten state to form a silicon liquid and a slag agent, stopping heating, extending the graphite pipe into the bottom of the silicon liquid, and then filling the silicon liquid with gas; at the end of gas filling, moving the graphite pipe to the surface layer of the slag agent, then performing vacuum pumping to the other end of the graphite pipe by a vacuum tank, letting the slag agent of the upper layer enter the slag storer under the action of pressure difference, simultaneously extending the graphite pipe downward, ensuring the bottom end of the graphite pipe to dip into the slag agent till all the slag agent enters the slag storer, then opening the slag storer and taking the slag agent out. The device provided by the invention has the advantages of convenient reconstruction and installation, and simple operation. The graphite pipe can extract the slag agent cleanly and dump the slag agent, so that the finally purified polysilicon has improved quality and high yield of primary product, and no dust or other garbage can be generated during production. Thus, the device is applicable to industrial mass production.

Owner:QINGDAO NEW ENERGY SOLUTIONS

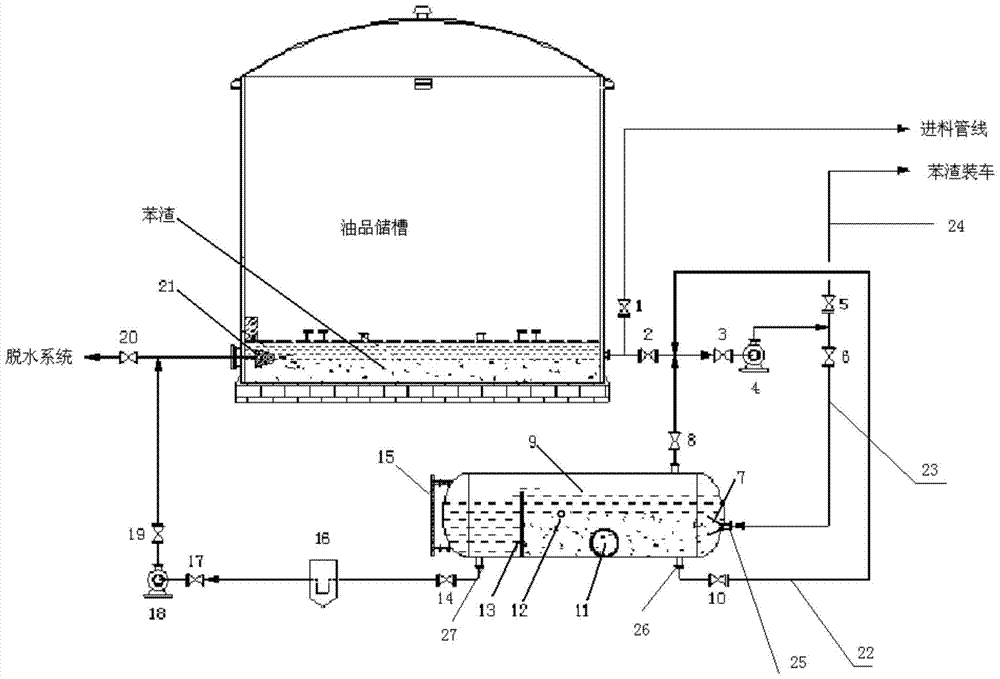

A light oil tank circulation slag flushing device and slag flushing cleaning method

ActiveCN104690053BAvoid making dehydration difficultAvoid elevated benzene slag contentHollow article cleaningFiltration circuitsSlagPrecipitation

The invention relates to a light oil tank circulating slag flushing device. A circulating slag flushing branch circuit is externally connected to a light oil tank feeding pipeline, and comprises a first circulating slag flushing pump, a benzene slag sedimentation tank and a second circulating slag flushing pump, wherein the first circulating slag flushing pump, the benzene slag sedimentation tank and the second circulating slag flushing pump are connected together in series through pipelines; an inlet of the first circulating slag flushing pump is communicated with the light oil tank feeding pipeline, and the benzene slag sedimentation tank is a horizontal sealed tank; a slag baffle is longitudinally arranged inside the benzene slag sedimentation tank, and the area in the benzene slag sedimentation tank is divided by the slag baffle into a benzene slag sedimentation area and a clear oil product area; a benzene outlet is connected with a benzene slag pipeline, and the benzene slag pipeline is communicated with a pipeline located between the first circulating slag flushing pump and the light oil tank feeding pipeline. The light oil tank circulating slag flushing device is simple in structure and convenient to improve, install and operate; storage tank circulating slag flushing cleaning is conducted regularly, accumulation of benzene slag in a storage tank is reduced, the continuous service cycle of the storage tank is prolonged, and stable operation of a follow-up processing system is guaranteed.

Owner:山东莱钢环友化工能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com