Coal bunker wall vibrating device

A vibrating device and warehouse wall technology, applied in the field of auxiliary devices, can solve the problems of small action area of the built-in vibrating rod, small resonance amplitude, unsatisfactory effect, etc., and achieve the effect of convenient installation, solution of sticky materials, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

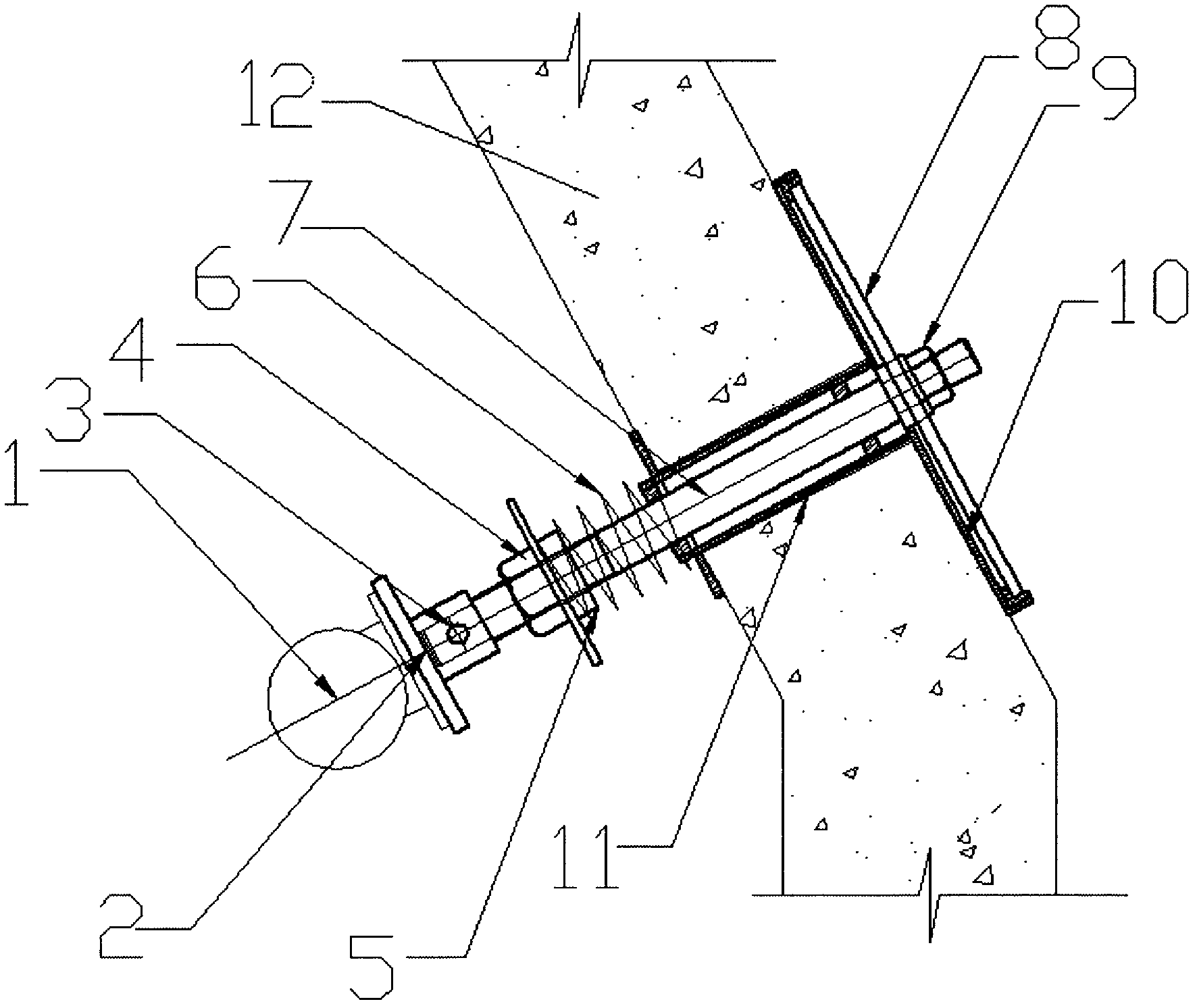

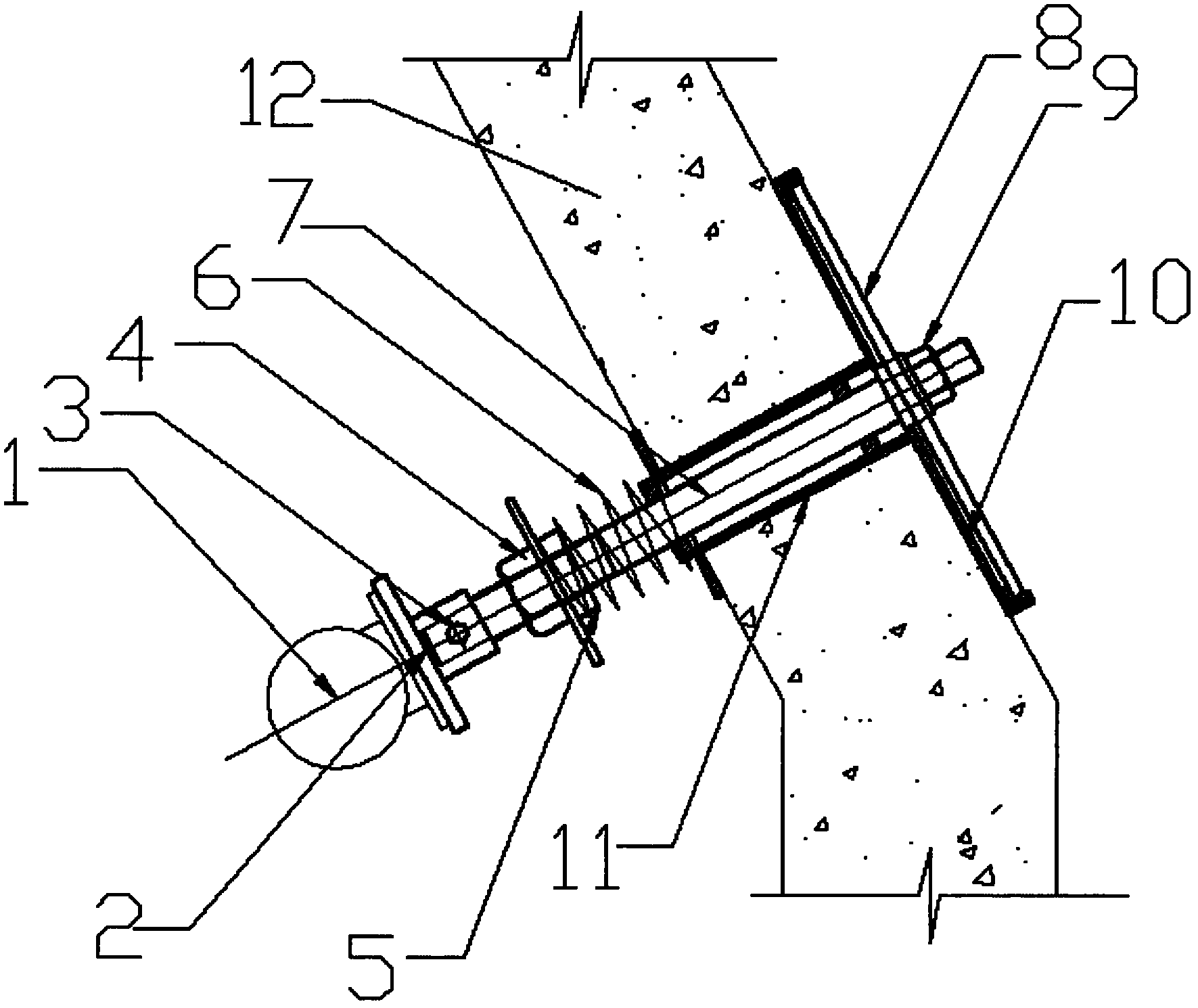

[0007] Referring to the accompanying drawings, the coal bunker wall vibrating device is characterized in that a fixed bottom plate 10 is welded on the inner wall of the silo wall 12, and the fixed bottom plate 10 and the silo wall 12 have corresponding openings, and the middle sleeve 11 is placed in the hole, and the middle sleeve 11 The vibrating connecting rod 7 is placed inside, and one end of the vibrating connecting rod 7 is provided with a vibrating plate 8. The vibrating plate 8 is fixed on the vibrating connecting rod 7 with a nut 9. The vibrating motor 1 and the vibrating motor base 2 are connected to the vibrating connecting rod 7 through the fixing pin 3 One end is connected, and the vibrating connecting rod 7 is provided with a tightening spring 6 outside, and the tightening spring 6 is fixed with the tightening nut 4 and the spring retaining ring 5, and the vibration amplitude of the vibration motor 1 is amplified with the tightening spring 6, so that the vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com