A light oil tank circulation slag flushing device and slag flushing cleaning method

A technology for light oil and slag flushing, applied in cleaning methods and utensils, separation methods, chemical instruments and methods, etc., can solve the problems of difficult environmental protection work, spontaneous combustion of ferrous sulfide, and high danger, saving resources, The effect of avoiding waste and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

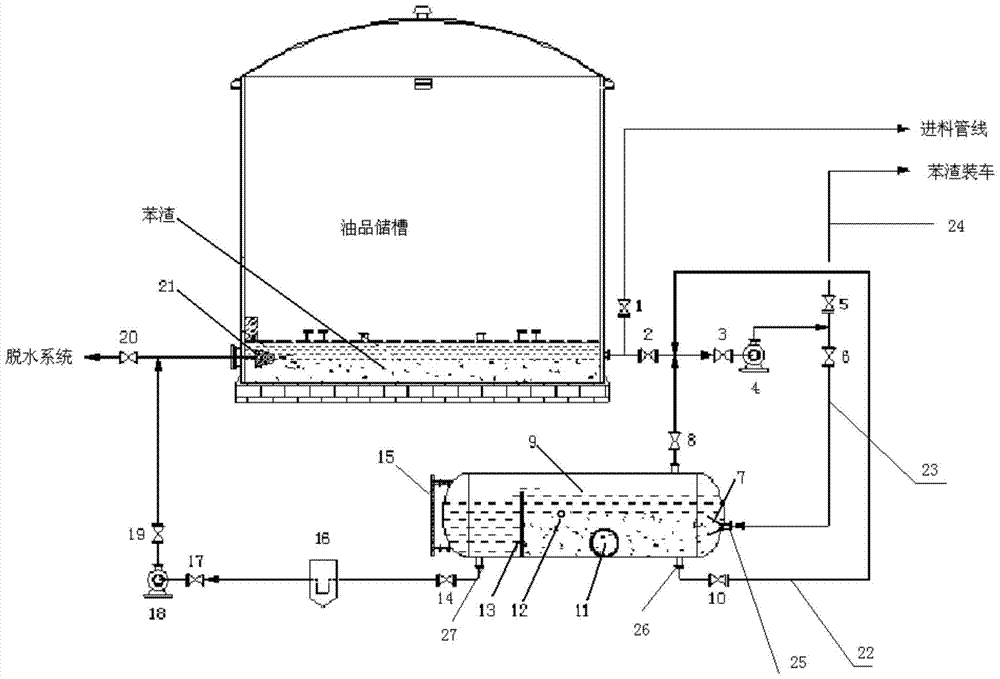

[0037] A light oil tank circulation slag flushing device, the structure is as follows figure 1 As shown, there is a circulating slag flushing branch externally connected to the feed pipeline of the light oil tank, and the circulating slag flushing branch includes a first circulating slag flushing pump 4, a benzene slag sedimentation tank 9 and a second circulating slag flushing pump connected in series through pipelines. The slag pump 18, the inlet of the first circulating slag washing pump 4 is connected with the feed pipeline of the light oil tank, and the outlet of the first circulating slag washing pump 4 is connected with an external benzene slag sending pipeline 24 and a circulating slag washing inlet pipe 23 through pipelines, Circulation flushing slag inlet pipe 23 is connected with feed port 25 of benzene slag sedimentation tank, benzene slag sedimentation tank outlet 27 is connected with the inlet of second circulation slag flushing pump 18, and the outlet of second c...

Embodiment 2

[0041] A light oil tank circulating slag flushing device, the structure is the same as that described in Embodiment 1, the difference is:

[0042] The top of the benzene slag sedimentation tank is provided with a full flow port connected to the inside of the benzene slag sedimentation tank. The full flow port is connected with a full flow pipeline, and the pipe between the full flow pipeline and the first circulation slag washing pump and the light oil tank feed line The flow path is connected, and the full-flow material enters the circulating slag flushing branch through the full-flow pipeline, and a full-flow control valve 8 is set on the full-flow pipeline.

Embodiment 3

[0044] A light oil tank circulating slag flushing device, the structure is the same as that described in Embodiment 1, the difference is:

[0045] There is also a nitrogen purge pipeline connected to the pipeline between the outgoing benzene slag pipeline 24 and the connection between the circulating slag flushing branch and the first circulating slag flushing pump.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com