Equipment for automatically controlling pressure of glass kiln

A glass furnace and pressure technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., to achieve high degree of automation, easy installation, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: A device for automatically controlling the pressure of a glass furnace.

[0018] Attached below Figure 1-3 , the specific embodiment of the present invention is described as follows.

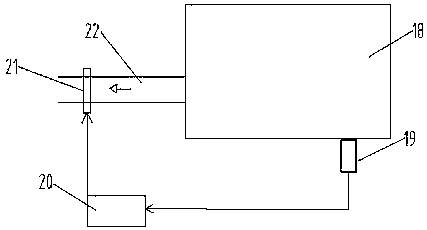

[0019] A device for automatically controlling the pressure of a glass furnace, including a gate device 21, which is installed on the flue gas outlet 22 of the glass furnace 18, and a pressure transmitter 19 is installed on the glass furnace 18, and the pressure transmitter The transmitter is connected to the PLC processor 20 through a signal line; the PLC processor is connected to the positioner 3 through a control signal connection line 17.

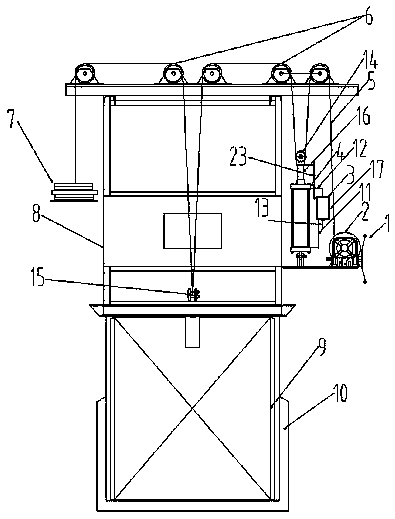

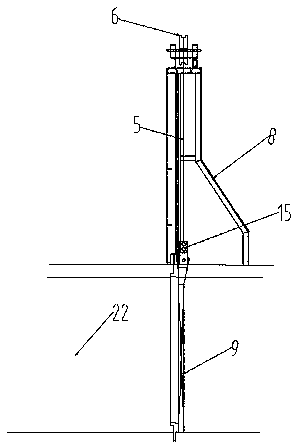

[0020] The specific structure of the gate device 21 is as follows: a gate frame 10 is arranged on the gate shell 8, a gate 9 is arranged on the gate frame, a certain pulley block 6 is arranged on the top of the gate shell, and a steel wire rope is installed on the fixed pulley block. 5. One end of the steel wire rope is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com