Solid-liquid separation method and device for polycrystalline silicon ingot

A technology of solid-liquid separation and polysilicon, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of low yield, waste of raw materials and energy, etc., and achieve high production efficiency and good product quality , Inhibit the effect of back diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

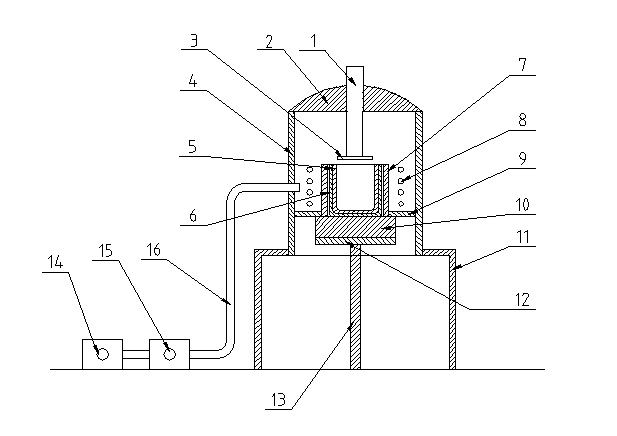

[0037] figure 1 It is the device for separating the solid and liquid of polycrystalline silicon ingot of the present invention.

[0038] This embodiment discloses a device capable of realizing the solid-liquid separation method of polycrystalline silicon ingot silicon, such as figure 1 As shown, the equipment includes a quartz crucible 5, a pressure plate 3 matched with the cross-section of the quartz crucible 5, a vacuuming device, a furnace cover 2 and a furnace body 4 that are matched; the furnace cover 2 and the furnace body 4 can form a sealed The accommodating space is connected to the vacuuming equipment through the vacuum pipe 16, and the vacuuming equipment is a mechanical pump 14 and a Roots pump 15 in series; an ingot pulling device is provided at the lower end of the furnace body 4, and the quartz crucible 5 is fixed on the ingot pulling An induction coil 8 is fixed on the outside of the quartz crucible 5 on the equipment close to the inside of the furnace body 4. Th...

Embodiment 2

[0046] The solid-liquid separation of polycrystalline silicon ingot silicon using the same equipment as in Example 1 includes the following steps:

[0047] The first step: smelting the ingot

[0048] Fill the quartz crucible 5 with silicon material accounting for 93% of the volume of the quartz crucible, and the purity of the silicon material is 99.7%. Close the furnace cover 2 to make the inside of the furnace body 4 in a sealed state, and use the mechanical pump 14 and the Roots pump 15 to seal the inside of the furnace body 4 Evacuate the vacuum to 3Pa, heat the induction coil 8, use a thermocouple to keep the temperature in the quartz crucible 5 at 1000℃, and fill the furnace body 4 with 6×10 helium with a purity of 99.9% 4 Pa, again use the mechanical pump 14 and the Roots pump 15 to vacuum to 3 Pa, and fill the furnace body 4 with helium 6×10 4 Pa, use the induction coil 8 to raise the temperature in the quartz crucible 5 to 1550°C. The molten silicon material in the quartz ...

Embodiment 3

[0052] The solid-liquid separation of polycrystalline silicon ingot silicon using the same equipment as in Example 1 includes the following steps:

[0053] The first step: smelting the ingot

[0054] Fill the quartz crucible 5 with silicon material accounting for 95% of the volume of the quartz crucible, and the purity of the silicon material is 99.9%. Close the furnace cover 2 to make the inside of the furnace body 4 in a sealed state, and use the mechanical pump 14 and the roots pump 15 to seal the furnace body 4 Evacuate to 7Pa, heat the induction coil 8, use a thermocouple to keep the temperature in the quartz crucible 5 at 1200℃, and fill the furnace body 4 with argon gas 8×10 4 Pa, the mechanical pump 14 and the Roots pump 15 are used again to vacuum to 7 Pa, and the furnace body 4 is filled with argon gas 8×10 4 Pa, use the induction coil 8 to raise the temperature in the quartz crucible 5 to 1650°C. The molten silicon material in the quartz crucible 5 is kept in the insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com