Silicon dioxide nanofiber membrane loaded with ZIF-8 and used for purifying air

A technology of silica and air purification, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of large volume, high filtration efficiency, large air flow, etc., achieve high filtration efficiency, efficient capture, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

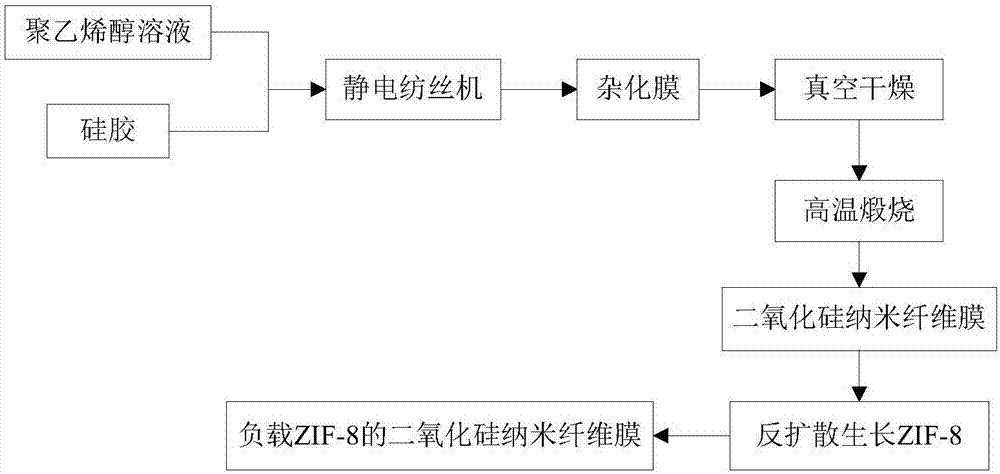

Method used

Image

Examples

Embodiment 1

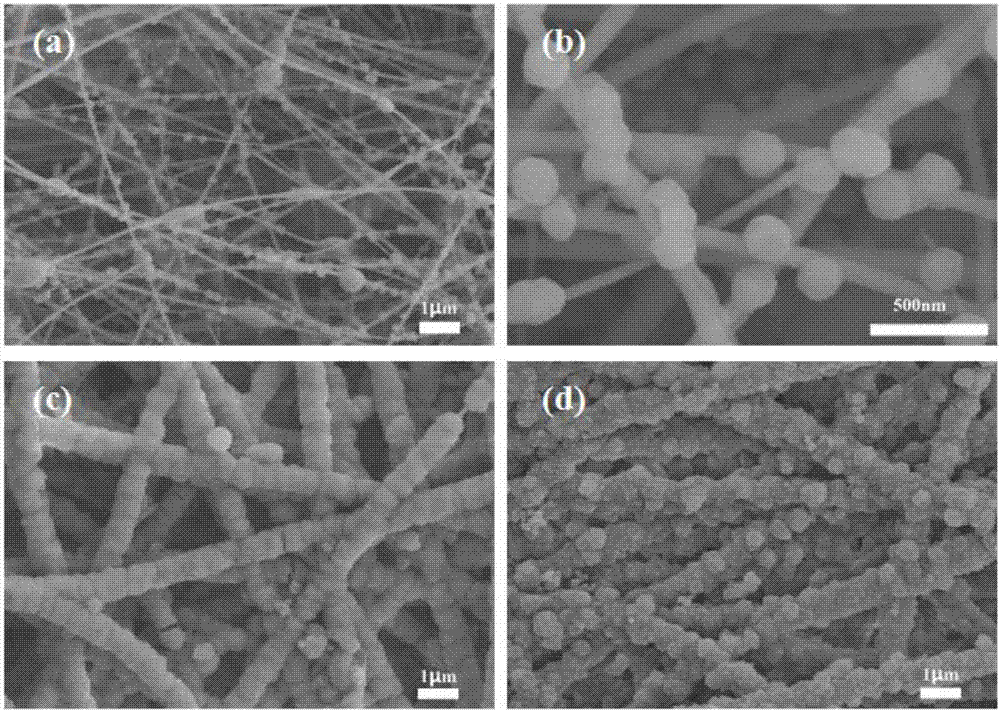

[0029] Configure a polyvinyl alcohol aqueous solution with a concentration of 10wt%, dissolve it in pure water; configure silica gel (the molar ratio of tetraethyl orthosilicate, water, and phosphoric acid is 1:10:0.01), and add phosphoric acid dropwise into tetraethyl orthosilicate Stir at room temperature for 10 hours for hydrolysis and polycondensation; take an equal mass of polyvinyl alcohol aqueous solution and silica gel and stir and mix evenly to obtain a spinning solution. The prepared spinning solution was filled in a syringe with a No. 21 flat needle for electrospinning. The injection speed was 1.0ml / h, the voltage was 18kV, the receiving distance was 20cm, and the reciprocating speed of the slide table was 3m / min. The humidity is 45%, and the relative temperature is 20°C. The collection device is a drum collector to obtain a hybrid film. The hybrid film was dried in a vacuum oven at 100°C for 2 hours to remove residual moisture; it was calcined in a muffle furnace, ...

Embodiment 2

[0032] Configure a polyvinyl alcohol aqueous solution with a concentration of 14wt%, dissolve it in pure water; configure silica gel (the molar ratio of tetraethyl orthosilicate, water, and phosphoric acid is 1:10:0.01), and add phosphoric acid dropwise into tetraethyl orthosilicate Stir at room temperature for 4 hours for hydrolysis and polycondensation; take an equal mass of polyvinyl alcohol aqueous solution and silica gel and stir and mix evenly to obtain a spinning solution. The prepared spinning solution was filled in a syringe with a No. 21 flat needle for electrospinning. The injection speed was 0.5ml / h, the voltage was 15kV, the receiving distance was 15cm, and the reciprocating speed of the slide table was 5m / min. The humidity is 50%, and the relative temperature is 30°C. The collection device is a drum collector to obtain a hybrid film. The hybrid membrane was dried in a vacuum oven at 60°C for 4 hours to remove residual moisture; it was calcined in a muffle furnace...

Embodiment 3

[0035]Configure a polyvinyl alcohol aqueous solution with a concentration of 8wt%, dissolve it in pure water; configure silica gel (the molar ratio of tetraethyl orthosilicate, water, and phosphoric acid is 1:11:0.01), and add phosphoric acid dropwise into tetraethyl orthosilicate Stir at room temperature for 6 hours for hydrolysis and polycondensation; take an equal mass of polyvinyl alcohol aqueous solution and silica gel and stir and mix evenly to obtain a spinning solution. Fill the prepared spinning solution into a syringe with a No. 21 flat needle for electrospinning. The injection speed is 1.5ml / h, the voltage is 25kV, the receiving distance is 30cm, and the reciprocating speed of the slide table is 4m / min. The humidity is 30%, and the relative temperature is 15°C. The collection device is a drum collector to obtain a hybrid film. The hybrid film was dried in a vacuum oven at 70°C for 8 hours to remove residual moisture; it was calcined in a muffle furnace, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com