Offline cleaning and evaluating device of reverse osmosis membrane element and application method of device

A reverse osmosis membrane and evaluation device technology, which is applied in the field of water treatment, can solve the problems of different pollution levels, reverse osmosis membrane performance degradation, and the inability to completely remove compound pollution, etc., to achieve recovery performance, high-efficiency membrane performance, and recovery membrane performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

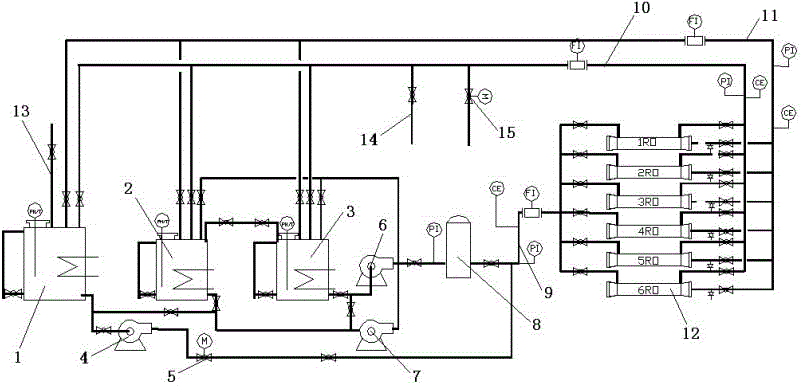

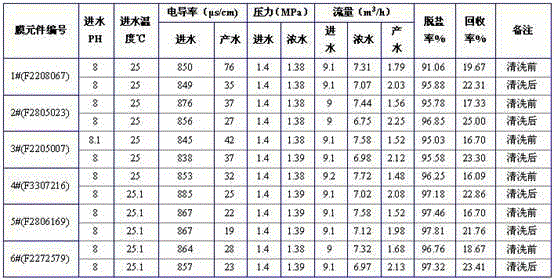

[0069] figure 1 It is a schematic structural diagram of the off-line cleaning and evaluation device for reverse osmosis membrane elements of the present invention. An off-line cleaning and evaluation device for reverse osmosis membrane elements, including a cleaning water tank, a test water tank, and a reverse osmosis cleaning detection device, characterized in that: the cleaning water tank includes a pickling water tank 2 and an alkali cleaning water tank 3, and the pickling water tank 2 and the alkali cleaning water tank 3 and the entrance of test water tank 1 are respectively equipped with pickling pump 7, alkali washing pump 6 and high-pressure pump 4, and the upper ends of pickling water tank 2, alkali washing water tank 3 and test water tank 1 are respectively equipped with pH / temperature instruments, and steam heating is reserved Tube holes; the reverse osmosis cleaning detection device includes a pressure vessel 12, a valve, a control box, an electrical control mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com