Recovery method for aroma components in production process for instant tea powder

A technology of aroma components and production process, which is applied in the direction of tea spices, etc., can solve the problems of high industrial production cost and high polarity, and achieve the effects of improving utilization rate, mild operating temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

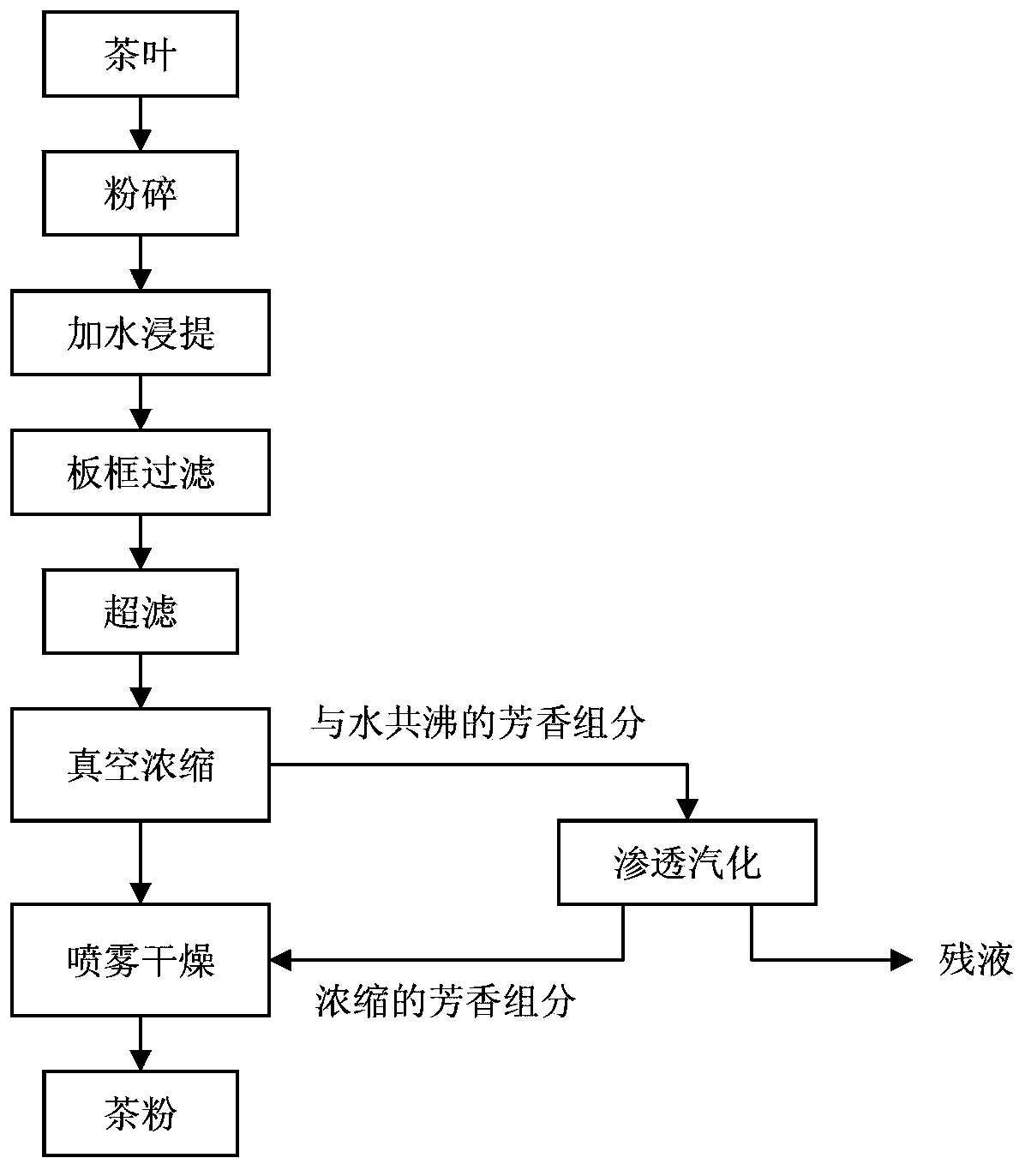

Method used

Image

Examples

Embodiment 1

[0030] Prepare powdered tea leaves (30 mesh) and water by mechanical crushing at a mass ratio of 1:20, leaching at 90°C for 30 minutes, plate and frame filtration, ultrafiltration of the filtrate with a polypropylene hollow fiber membrane, and the filtrate at 0.1 Vacuum concentration under Mpa for 24 hours, the concentration temperature is 50°C, the concentrated solution is spray-dried to obtain tea powder, the spray drying inlet temperature is 200°C, and the outlet temperature is 80°C. The condensed water in the concentration step contains a large amount of unused aromatics. As the feed liquid of pervaporation, the operating conditions of pervaporation are temperature 20°C, pressure 500Pa, feed rate 100L / min, and time 24h. The permeability of aromatic substances is 0.46Kg / m -2 ·h The yield of aromatics measured by GC-MS is higher than 90%, while the yield of conventional processes does not exceed 70%.

Embodiment 2

[0032] The tea leaves and water made into powder (40 mesh) by mechanical crushing were prepared according to the mass ratio of 1:25, extracted at 95°C for 35 minutes, plate and frame filtered, and the filtrate was ultrafiltered with a polypropylene hollow fiber membrane at 0.1 Vacuum concentration under Mpa for 28 hours, the concentration temperature is 55°C, the concentrated solution is spray-dried to obtain tea powder, the spray-drying inlet temperature is 230°C, and the outlet temperature is 100°C. The condensed water in the concentration step contains a large amount of unused aromatics. As the feed liquid of pervaporation, the operating conditions of pervaporation are temperature 30°C, pressure 200Pa, feed rate 140L / min, and time 28h. The permeability of aromatic substances is 0.67Kg / m -2 h, the yield of aromatics measured by GC-MS is higher than 95%, while the yield of conventional processes does not exceed 70%.

Embodiment 3

[0034] Prepare powdered tea leaves (60 mesh) and water by mechanical crushing at a mass ratio of 1:30, extract at 100°C for 40 minutes, filter with a plate and frame, and ultrafilter the filtrate with a polypropylene hollow fiber membrane at 0.1 Vacuum concentration under Mpa for 32 hours, the concentration temperature is 60°C, the concentrated solution is spray-dried to obtain tea powder, the spray drying inlet temperature is 260°C, and the outlet temperature is 120°C. The condensed water in the concentration step contains a large amount of unused aromatics. As the feed liquid of pervaporation, the operating conditions of pervaporation are temperature 40°C, pressure 1000Pa, feed rate 180L / min, and time 32h. The permeability of aromatic substances is 0.33Kg / m -2 h, the yield of aromatics measured by GC-MS is higher than 85%, while the yield of conventional process is not more than 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com