Composite reverse osmosis membrane with high-intensity anti-pollution layer and preparation method thereof

A reverse osmosis membrane, anti-pollution technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems that it is difficult to ensure the PVA antifouling layer, and the degree of cross-linking is difficult to achieve high, so as to improve the anti-fouling effect. Water scouring and dissolving performance, anti-pollution ability, and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

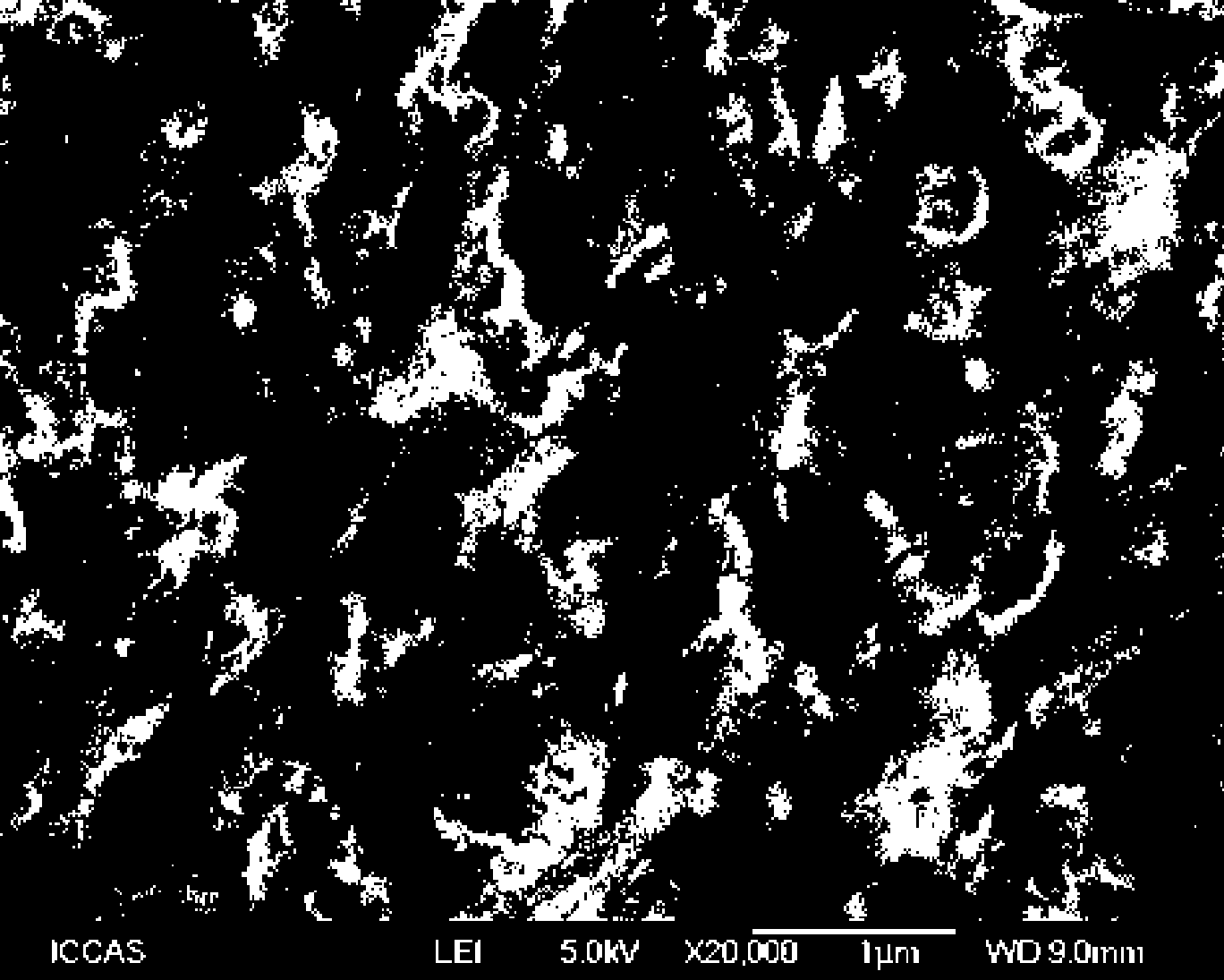

[0020] Embodiment 1: prepare composite reverse osmosis membrane according to the following steps:

[0021] (1) Preparation of A solution: take 3.75g of PVA with a degree of polymerization of 2600 and a degree of alcoholysis of 99% and dissolve it in 1496.25g of water, heat to 95°C, stir until completely dissolved to obtain a 0.25% PVA solution.

[0022] (2) Preparation of solution B: Weigh 32.0 g of glutaraldehyde and 40.0 g of hydrochloric acid and dissolve them in 328.0 g of water, stir well to obtain a mixed solution of 8% glutaraldehyde and 10% hydrochloric acid.

[0023] (3) The polysulfone support membrane with the polyamide dense layer polymerized on the outside is contacted with the A solution for 5s, removes excess solution, and forms a PVA layer on the polyamide surface; then this polysulfone support layer is contacted with the B solution for 5s, and then Place in an oven at 80°C for 10 minutes of cross-linking reaction to obtain a composite reverse osmosis membrane ...

Embodiment 2

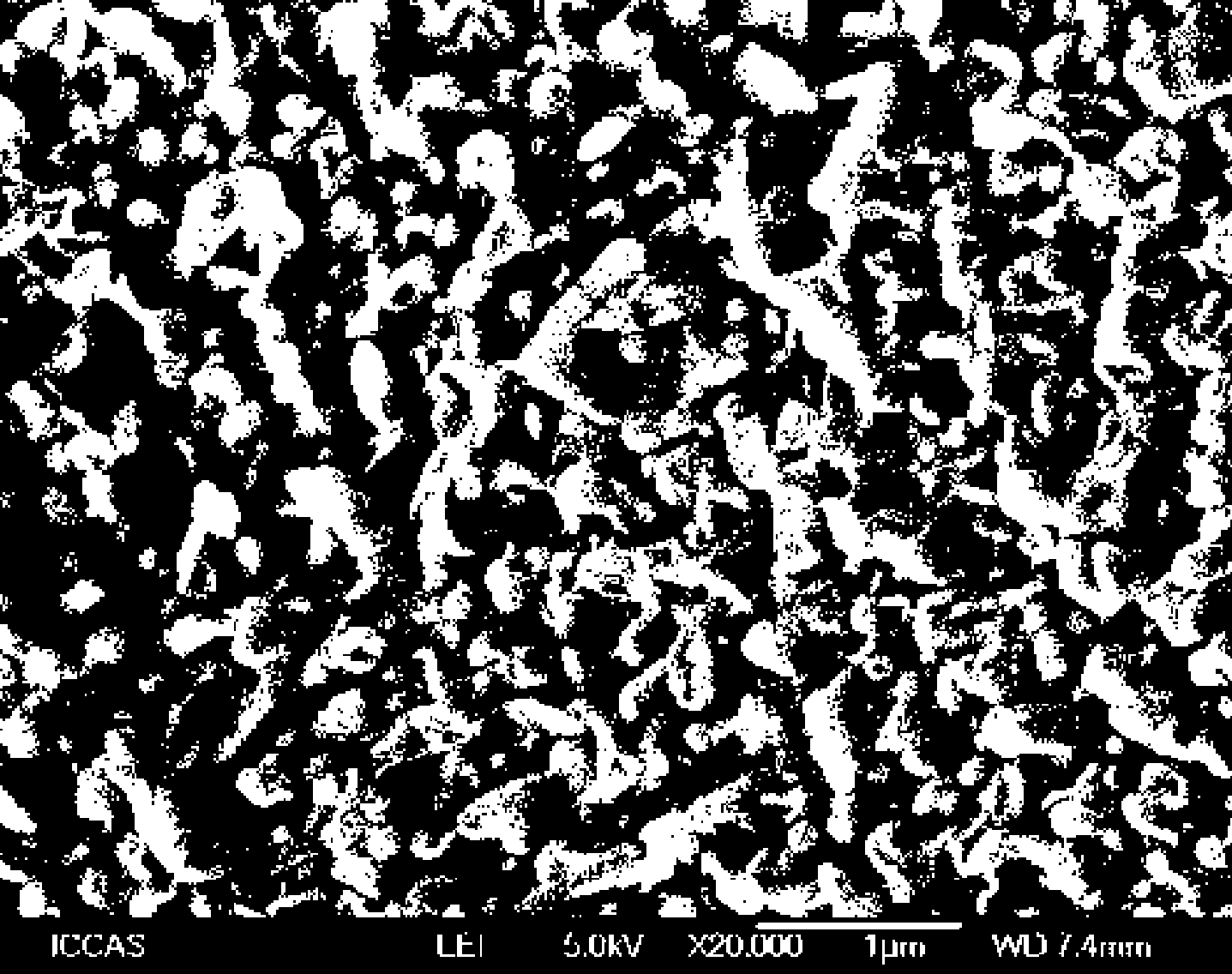

[0025] Embodiment 2: prepare composite reverse osmosis membrane according to the following steps:

[0026] (1) Preparation of A solution: same as Example 1.

[0027] (2) Preparation of B solution: same as in Example 1.

[0028] (3) The polysulfone supporting membrane with the polyamide dense layer polymerized on the outside is contacted with the A solution for 10s, and the excess solution is removed to form a PVA layer on the polyamide surface; then this polysulfone supporting layer is contacted with the B solution for 5s, and then Place in an oven at 80°C for 10 minutes of cross-linking reaction to obtain a composite reverse osmosis membrane with a high-strength anti-pollution layer.

[0029] Take the diaphragm and test it on a cross-flow diaphragm testing platform under the test conditions of 2000ppm NaCl aqueous solution, 225psi operating pressure, temperature 25°C, and pH value 6.5-7.5. The results are shown in Table 1.

Embodiment 3

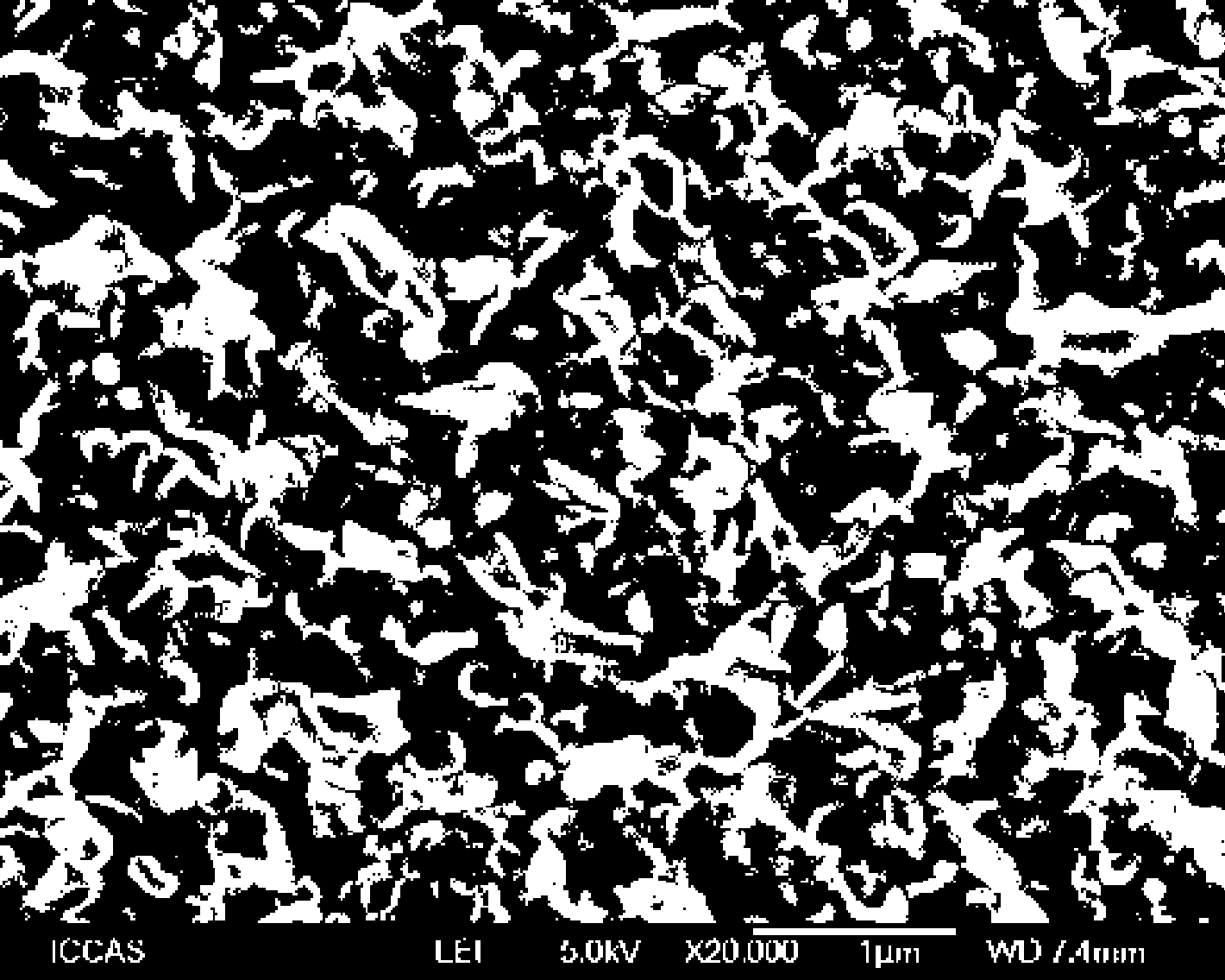

[0030] Embodiment 3: prepare composite reverse osmosis membrane according to the following steps:

[0031] (1) Preparation of A solution: same as Example 1.

[0032] (2) Preparation of B solution: same as in Example 1.

[0033] (3) The polysulfone support membrane with the polyamide dense layer polymerized on the outside is contacted with the A solution for 20s, and the excess solution is removed to form a PVA layer on the polyamide surface; then this polysulfone support layer is contacted with the B solution for 5s, and then Place in an oven at 80°C for 10 minutes of cross-linking reaction to obtain a composite reverse osmosis membrane with a high-strength anti-pollution layer.

[0034] Take the diaphragm and test it on a cross-flow diaphragm testing platform under the test conditions of 2000ppm NaCl aqueous solution, 225psi operating pressure, temperature 25°C, and pH value 6.5-7.5. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com