Direct methanol fuel cell capable of realizing pure methanol supply

A methanol fuel cell and fuel cell technology, which is used in fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., can solve problems such as difficulty in maintaining efficient battery operation, unbalanced reactant concentration ratios, and low methanol vapor partial pressure, and achieves The effect of low cost, improved fuel utilization, and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments, but it should be noted that the scope of protection claimed in the present invention is not limited to the scope expressed by the embodiments.

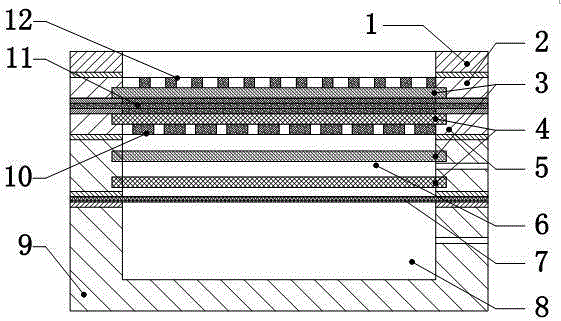

[0024] like figure 1 As shown in the figure, a fuel cell for realizing direct methanol fuel cell feeding with pure methanol includes a cell casing 9 with an open inner cavity, which is fixed on the cell casing 9 to divide the inner cavity into a methanol fuel cavity 8 and a The pervaporation membrane 7 of the steam chamber 6, the pervaporation membrane 7 of this embodiment adopts the N117 proton exchange membrane of DuPont Company, and its effective working area and the opening area of the steam chamber 6 are the same as 28mmx28mm,

[0025] An anode flow field plate 10 , a membrane electrode 11 , and a cathode flow field plate 12 are sequentially stacked above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com