Chiral MOFs functional material as well as preparation method and purpose thereof

A functional material and chirality technology, which can be applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

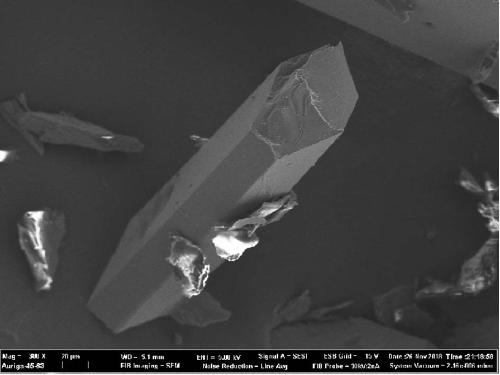

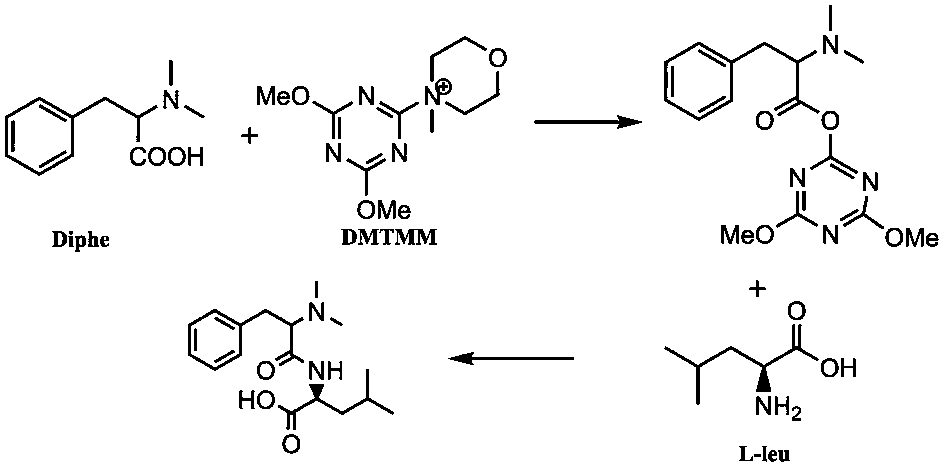

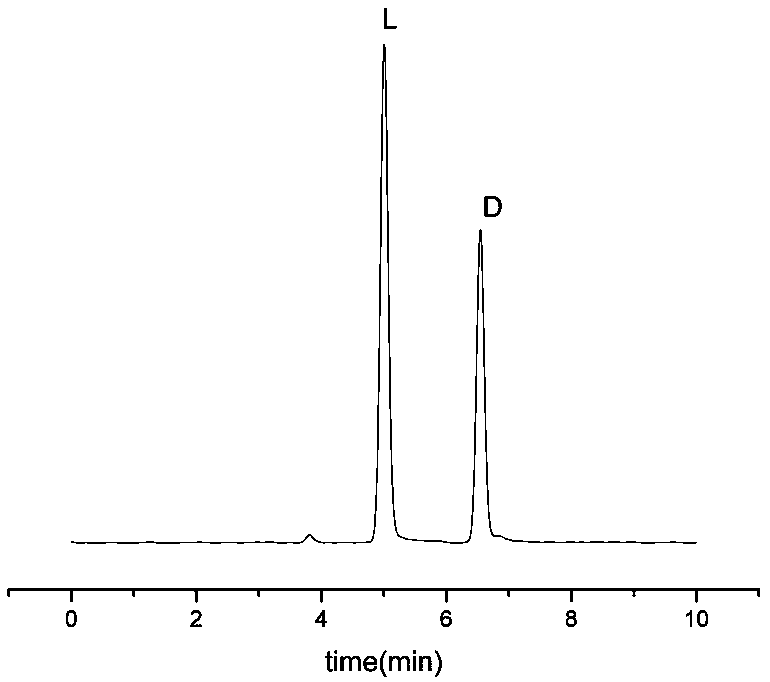

[0025] Example 1 Prepare a chiral MOFs functional material, the metal of which is zinc salt, the specific preparation method is: weigh 0.9mmol (0.27g) zinc nitrate hexahydrate and 0.9mmol (0.15g) L-phenylalanine dissolved in 2.5mL deionized water to get solution A, weigh 0.9mmol (0.16g) 1,2-bis(4-pyridyl)ethylene and dissolve it in 7.5mL anhydrous methanol to get solution B, mix solution A and solution B evenly Transfer to a reaction kettle with a polytetrafluoroethylene lining, and then place the reaction kettle in a muffle furnace for crystallization at 120°C for 72 hours. After the reaction, use programmed cooling (programmed cooling helps crystal growth). The reactor was cooled to room temperature, then filtered, washed three times with fresh methanol / water mixture with a volume ratio of 3:1, then washed three times with fresh anhydrous methanol, and finally dried in vacuum at 60°C for 24 hours to obtain orange crystals. Sexual MOFs functional materials. It has been verif...

Embodiment 2

[0028] Applicant compared with Cu 2+ As the ion source, chiral MOFs were prepared with L-phenylalanine and 1,2-bis(4-pyridyl)ethylene as ligands. The specific preparation method was: weigh 0.9mmol (0.18g) copper acetate monohydrate and 0.9mmol (0.15g) of L-phenylalanine were dissolved in 2.5mL of deionized water to obtain solution C, and 0.9mmol (0.16g) of 1,2-di(4-pyridyl)ethylene was weighed and dissolved in 7.5mL of anhydrous Solution B was obtained in methanol, and solution C and solution B were mixed uniformly and then transferred to a reaction kettle, and then the reaction kettle was placed in a muffle furnace for crystallization at 120°C for 72 hours, and then the reaction kettle was cooled to room temperature using a temperature program. No crystals were precipitated out in the reactor.

Embodiment 3

[0030] The applicant also compared with Co 2+ As an ion source, chiral MOFs were prepared with L-phenylalanine and 1,2-bis(4-pyridyl)ethylene as ligands. The specific preparation method was the same as in Example 2, and the difference from Example 2 was only The reason is to replace copper acetate monohydrate with 0.9 mmol (0.26 g) of cobalt nitrate hexahydrate. After cooling the reactor, it was found that no crystals grew in the mixed solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com