Selective contact crystalline silicon heterojunction solar cell and preparation method thereof

A technology of solar cells, crystalline silicon, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

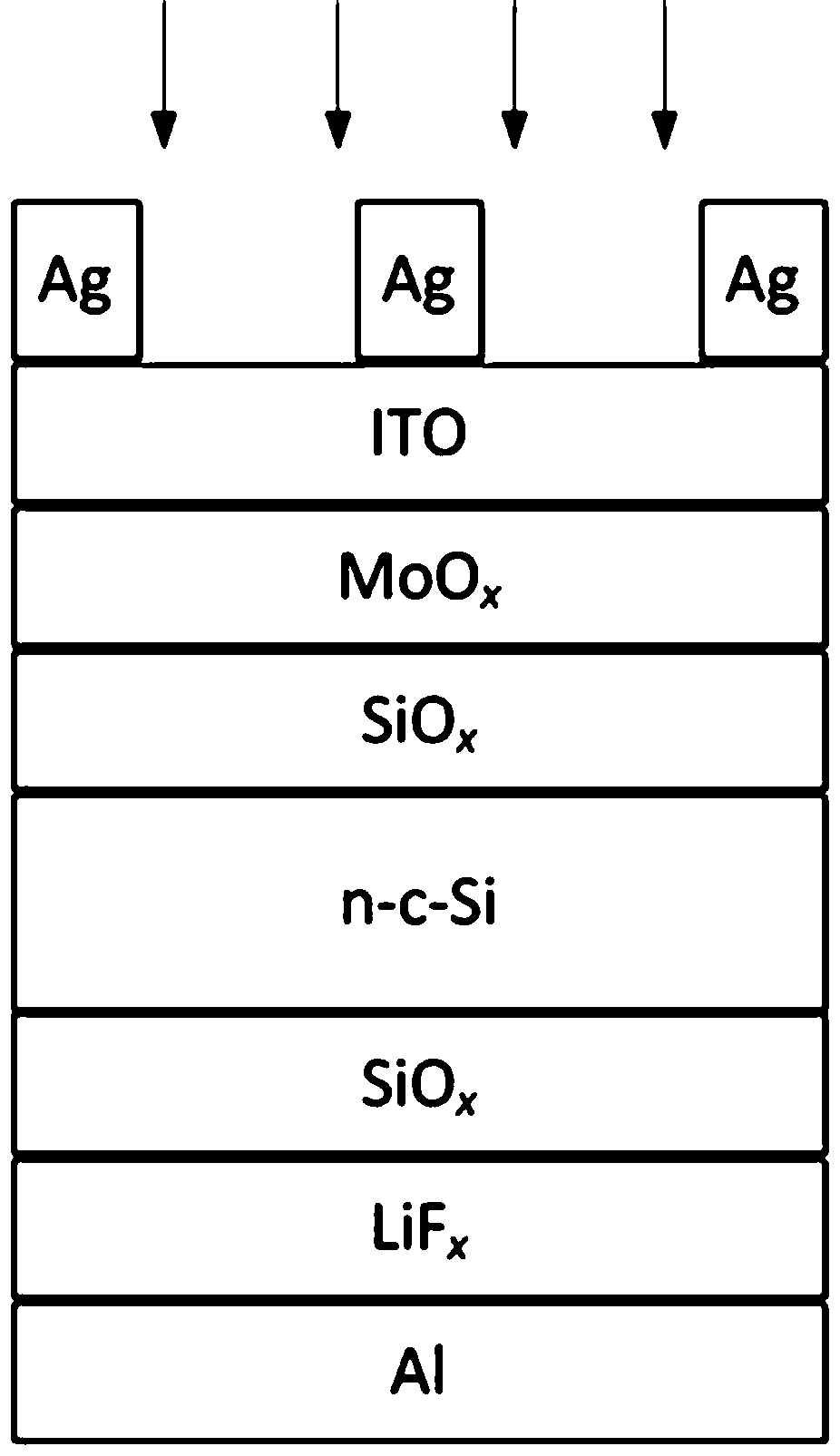

[0018] Such as figure 1 As shown, the solar cell structure described in this embodiment is divided into several layers, from top to bottom: Ag / ITO / MoO x / SiO y / n-c-Si / SiO y / LiF z / Al, where Ag is metallic silver, ITO is tin-doped indium oxide transparent conductive film, MoO x It is molybdenum oxide, x=2.3~3.0, SiO y It is silicon oxide, y=1.5~2.0, n-c-Si is n-type single crystal silicon, LiF z It is lithium fluoride, z=0.8~1.0, and Al is metal aluminum.

[0019] The preparation method is as follows: firstly, chemically treat the surface of the single crystal silicon wafer to remove the damaged layer and remove surface contamination impurities, and then use the nitric acid oxidation method to grow a layer of ultra-thin SiO on the front and rear surfaces of the silicon wafer. y layer (1.0-1.3nm), and then sequentially grow MoO on the front side of the silicon wafer x , ITO, Ag, and LiF are grown sequentially on the back of the silicon wafer x and Al.

[0020] Specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com