Organic ligand for MOF (Metal Organic Framework) and preparation method of organic ligand as well as separation membrane containing organic ligand MOF and preparation method of separation membrane

An organic ligand, separation membrane technology, applied in osmosis/dialysis water/sewage treatment, seawater treatment, etc., can solve problems such as difficulty in applicability, improve chemical stability, improve transmission, and offset ion flux reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

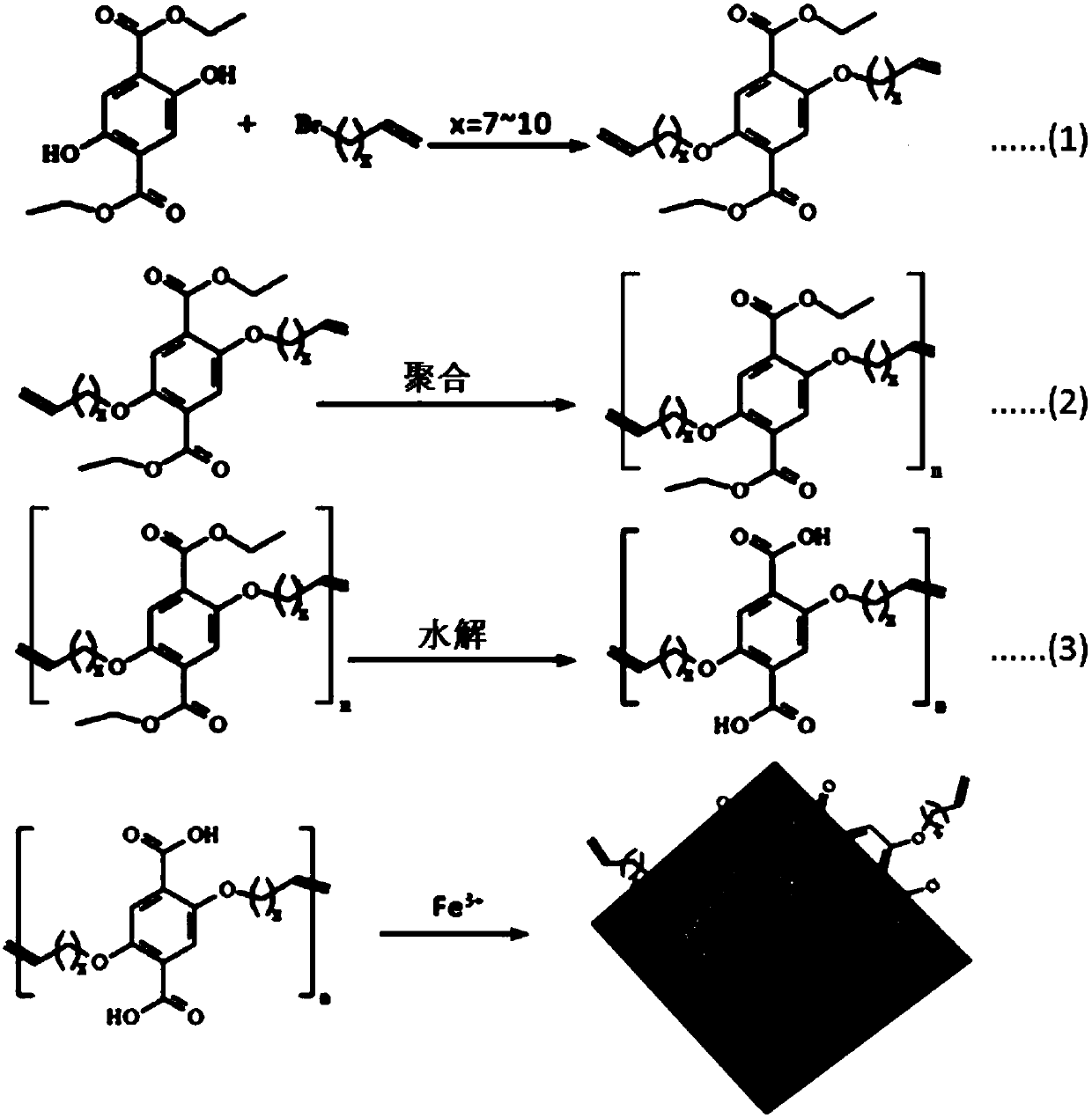

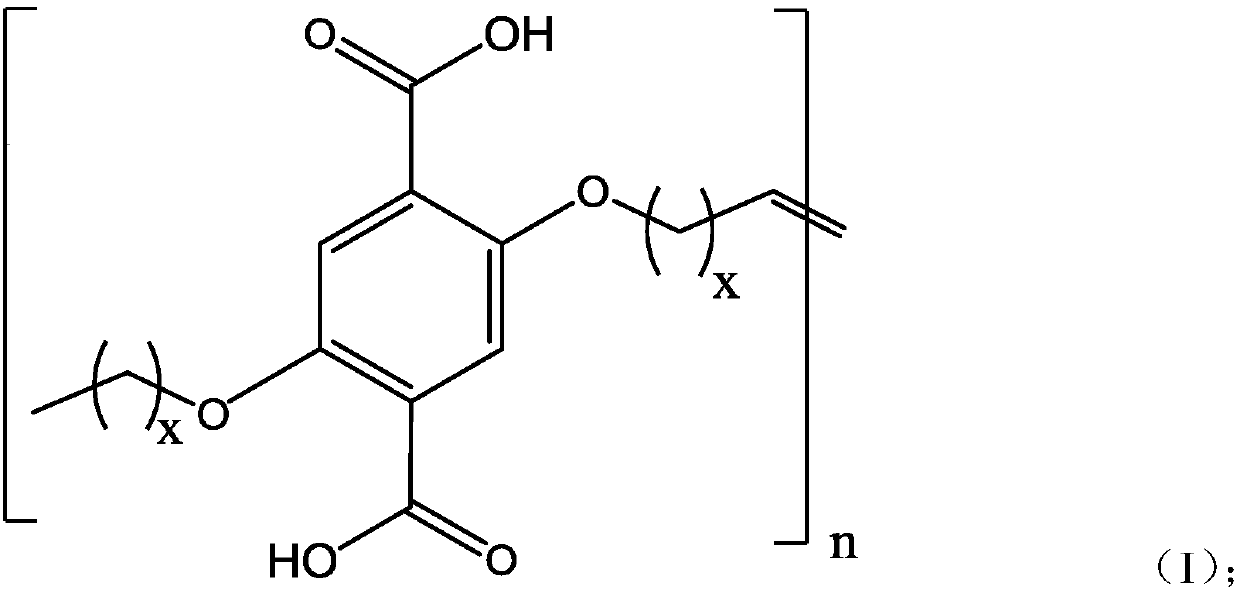

[0067] The invention provides a method for preparing an organic ligand for MOF, comprising the following steps:

[0068] 1) after mixing terephthalic acid diester, bromo-1-alkene, acid-binding agent and the first solvent, carry out condensation reaction, obtain the monomer containing double bond;

[0069] 2) Under the action of a catalyst, after the double bond-containing intermediate obtained in the above steps is polymerized in a second solvent, a polymer containing a terephthalic acid diester structure is obtained;

[0070] 3) The polymer containing the terephthalic acid diester structure obtained in the above steps and the base are hydrolyzed in a third solvent, and then reacted with an acidic substance to obtain an organic ligand for the MOF.

[0071] In the invention, firstly, after mixing terephthalic acid diester, bromo-1-alkene, acid-binding agent and the first solvent, condensation reaction is carried out to obtain monomers containing double bonds.

[0072] The pres...

Embodiment 1

[0133] 1.1 Preparation of polymeric organic ligands containing terephthalic acid structure

[0134] 3.2mmol of diethyl terephthalate, 12.0mmol of 7-bromo-1-alkene and 16.0mmol of potassium carbonate were dissolved in 24ml of N,N-dimethylformamide, and the solution was reacted at 90°C After 24 hours, potassium carbonate was filtered off, and N,N-dimethylformamide was evaporated to obtain monomer (1).

[0135] 0.3mmol of monomer (1) and 0.032mmol of the second-generation Grubbs catalyst were dissolved in 6ml of methylene chloride, and this solution was reacted at 40°C for 8h, and it was precipitated in 30ml of methanol, and the solid was dried to obtain a polymer ( 2).

[0136] Dissolve 0.3mmol of polymer (2) and 4.5mmol of potassium hydroxide in 10ml of dimethyl sulfoxide, react at 90°C for 12h until the solution is clear, then add 2M HCl dropwise until the pH of the solution is 1, and then dissolve the resulting The solid was repeatedly washed with 30 ml of methanol and 30 m...

Embodiment 2

[0146]2.1 Preparation of polymeric organic ligands containing terephthalic acid structure

[0147] 3.2mmol of diethyl terephthalate, 12.8mmol of 8-bromo-1-alkene and 16.0mmol of potassium carbonate were dissolved in 24ml of N,N-dimethylformamide, and the solution was reacted at 80°C After 26 hours, potassium carbonate was filtered off, and N,N-dimethylformamide was evaporated to obtain monomer (1).

[0148] The first generation Grubbs catalyst of 0.3mmol monomer (1) and 0.034mmol was dissolved in 6ml methylene chloride, and this solution was reacted at 35°C for 7h, and it was precipitated in 30ml methanol, and the solid was dried to obtain polymer (2 ).

[0149] Dissolve 0.3mmol of polymer (2) and 4.5mmol of potassium hydroxide in 10ml of dimethyl sulfoxide, react at 100°C for 10h until the solution is clear, then add 2M HCl dropwise until the pH of the solution is 1, and then dissolve the resulting The solid was repeatedly washed with 30 ml of methanol and 30 ml of acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com