Method for selectively separating arsenic trioxide from non-ferrous metal smelter off-gas

A technology for arsenic trioxide and smelting flue gas, applied in chemical instruments and methods, inorganic chemistry, arsenic compounds, etc., can solve the problems of increased toxicity, air pollution, and high treatment costs, achieve high separation rate, avoid smoke and dust treatment, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

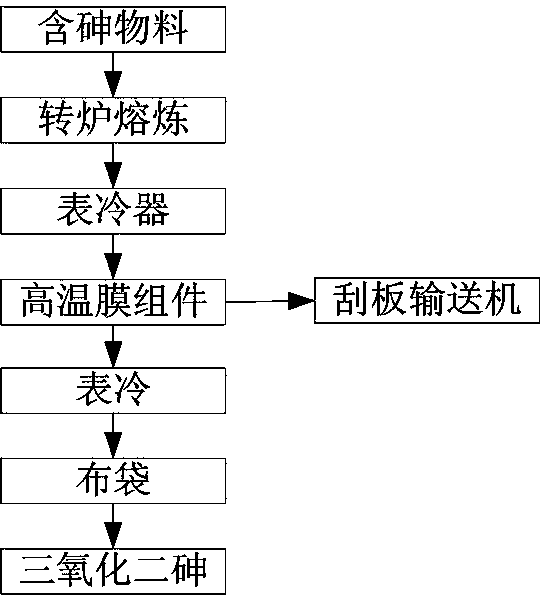

[0012] The present invention will be further described below in conjunction with the block diagram of technological process shown in accompanying drawing, and in conjunction with examples.

[0013] The method for extracting arsenic trioxide from nonferrous metal smelting flue gas comprises the following steps:

[0014] (1) Fill the arsenic-containing material according to the capacity of the converter, raise the temperature in the furnace to 200°C and keep it warm for 60 minutes, the moisture in the arsenic-containing material in the furnace becomes water vapor and is discharged by the fan.

[0015] (2) After the next process, raise the furnace temperature to 900~1100°C and keep it warm for 60~120 minutes. Under this temperature condition, the arsenic-containing material is oxidized into arsenic trioxide gas, and other metals are oxidized into oxides. The smoke enters in sequence Purified in the surface cooler and electrostatic precipitator, the purified high-temperature flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com