Waste lithium ion battery recovery method

A lithium-ion battery and a recovery method technology, which is applied in the field of recovery of waste positive electrode active materials, can solve the problems of low purity of recovered products, low lithium recovery rate, increased production cost, etc., and achieve good Li separation selectivity and recovery rate, avoiding the effects of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

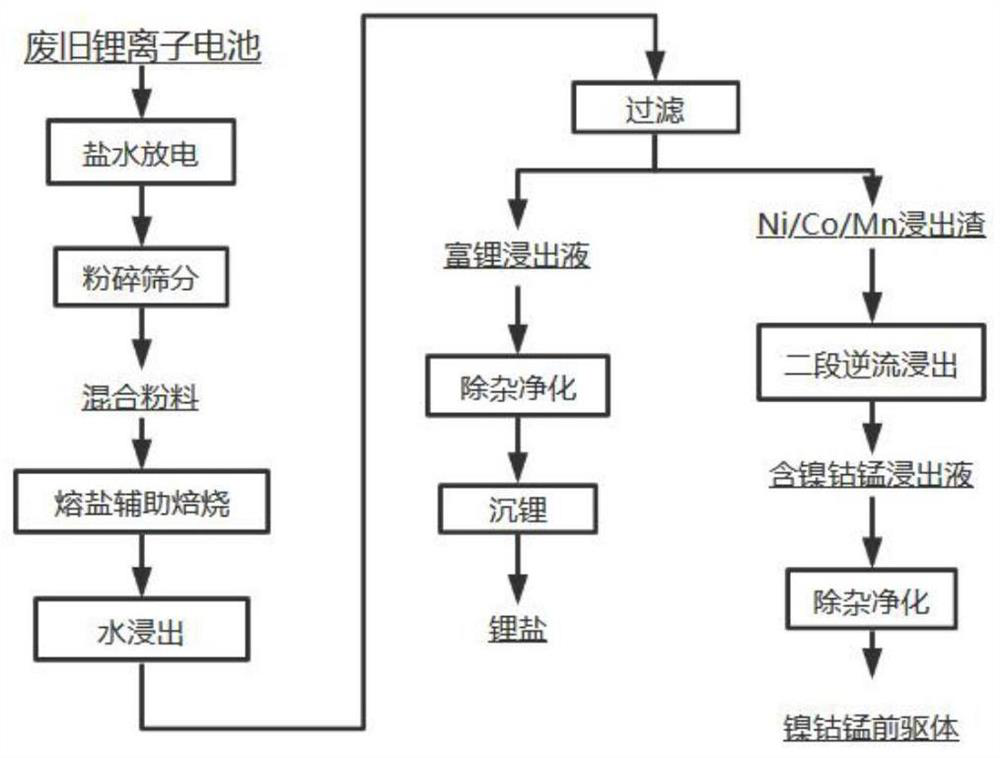

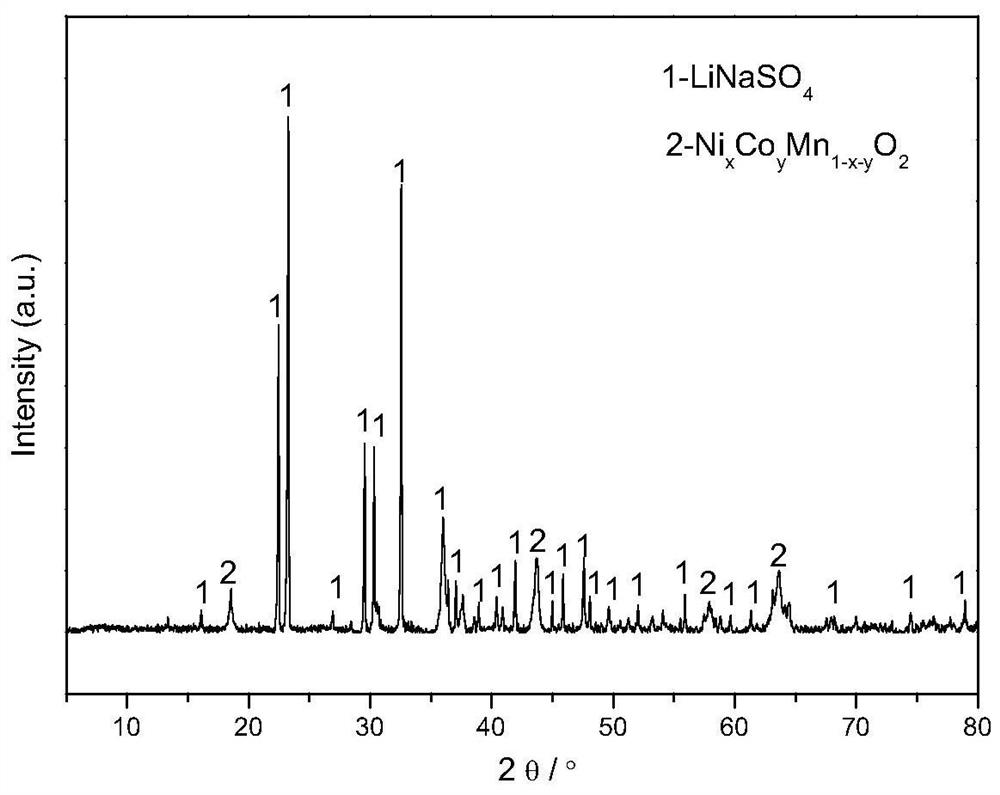

[0079] waste LiNi 0.5 co 0.2 mn 0.3 o 2 The ternary lithium-ion battery is soaked in 5% sulfurous acid solution until the end-of-discharge voltage is 1V, disassembled to obtain the cell, and then mechanically crushed as a whole, and sieved out the debris with a particle size of less than 0.1mm (cell mix material). Gained fragments are uniformly mixed with sodium bisulfate, and the specific parameters are as follows: the positive active material and NaHSO in the battery compound (the weight content of the positive active material is 80%) 4 Mix evenly at a mass ratio of 5:6. Then put the mixed powder into a tube furnace for roasting, the specific parameters are as follows: the roasting temperature is 600° C., and the roasting time is 60 minutes. After the roasting is completed, the obtained samples are subjected to water leaching, and the specific parameters are as follows: leaching temperature 25°C, leaching time 20min, leaching solid-liquid ratio 60g / L; Li leaching soluti...

Embodiment 2

[0084] Compared with Example 1, the main difference is that the mass ratio of the positive electrode active material to sodium bisulfate is controlled to be 5:3. Specifically:

[0085] Adopt the electric core compound material of embodiment 1, the electric core compound material (based on the positive electrode active material weight) and NaHSO 4 Mix evenly at a mass ratio of 5:3. Then put the mixed powder into a tube furnace for roasting, the specific parameters are as follows: the roasting temperature is 600° C., and the roasting time is 60 minutes. After the roasting is completed, the obtained samples are subjected to water leaching, and the specific parameters are as follows: leaching temperature 25°C, leaching time 20min, leaching solid-liquid ratio 60g / L; Li leaching solution and NCM leaching slag (water leaching slag) are obtained.

[0086] Add NaOH to the Li leaching solution, adjust the pH value of the water leaching to 4 to remove iron and aluminum, continue to add...

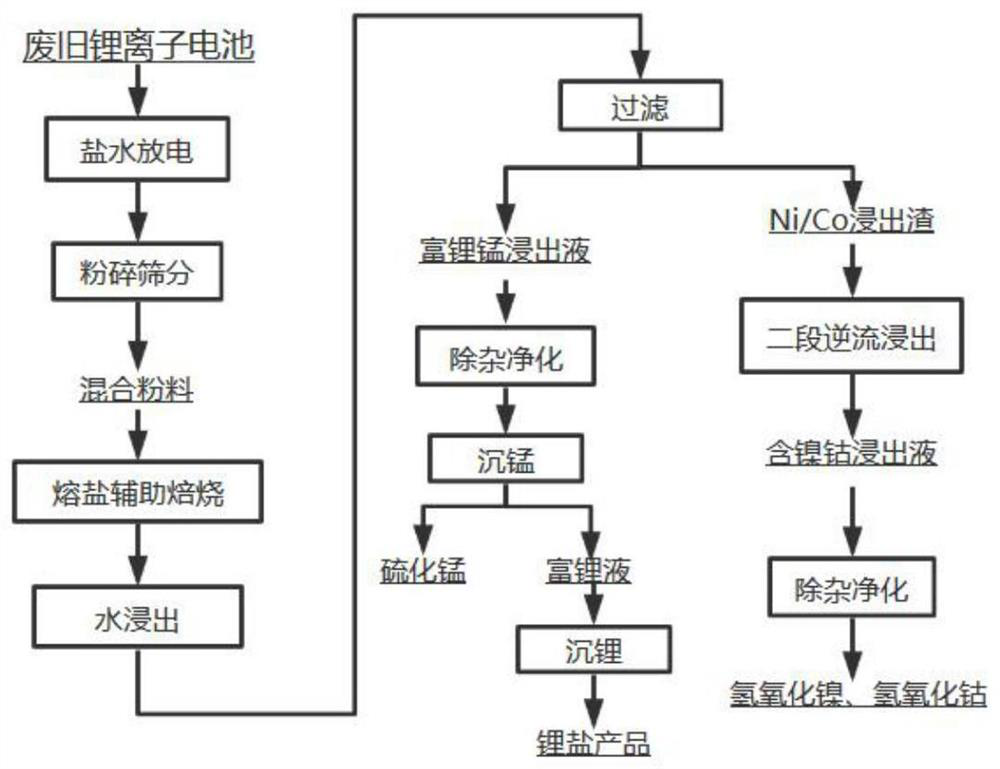

Embodiment 3

[0090] Compared with Example 2, the difference mainly lies in the use of MnSO 4 As additives, specifically:

[0091] Adopt the cell compound material of embodiment 2, take the positive electrode active material in the cell compound material as a benchmark, combine it with MnSO 4 Mix evenly at a mass ratio of 5:3. Then put the mixed powder into a tube furnace for roasting, the specific parameters are as follows: the roasting temperature is 600° C., and the roasting time is 60 minutes. After the roasting is completed, the obtained samples are subjected to water leaching, and the specific parameters are as follows: leaching temperature 25°C, leaching time 20min, leaching solid-liquid ratio 60g / L; Li leaching solution and NCM leaching slag (water leaching slag) are obtained.

[0092] Add NaOH to the Li leaching solution, adjust the pH value of water leaching to 4 to remove iron and aluminum, continue to add NaOH to the filtrate to adjust the pH value to 10, and then add Na 2 S ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com