Method for removing sesquioxide in complex and refractory collophanite

A technology of sesquioxide and collophosite, applied in flotation, solid separation, etc., can solve the problems of difficulty in industrialization implementation, difficult to guarantee the quality of concentrate, and many negative amplification effects, so as to improve the quality of concentrate and Phosphorus recovery rate, smooth beneficiation process and good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

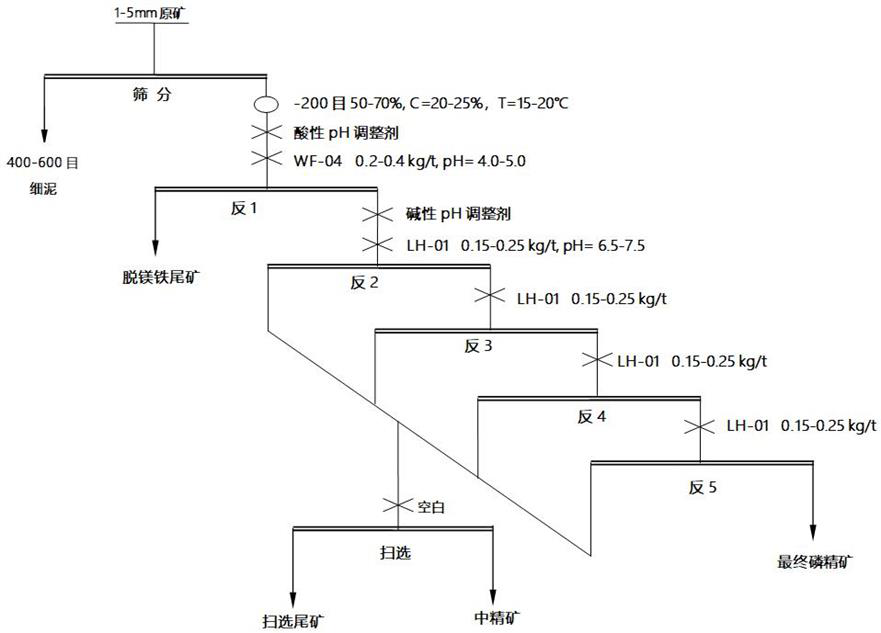

[0025] For a silicon-calcium colloidal phosphate rock in Kailin, Guizhou, raw ore P 2 o 5 29.40%, MgO 1.50%, SiO 2 13.17%, R 2 o 3 4.94%, according to the following process methods:

[0026] 1) Define sludge in advance: crush the lumpy colloidal phosphorus to 2mm, remove -400 mesh fine sludge through wet sieving, and the +400 mesh coarse particle grade part enters the grinding and floating operation;

[0027] 2) Coarse grade grinding: Grind the +400 mesh coarse grade product after fine mud removal to -200 mesh, accounting for 65%, adjust the concentration of the selected ore pulp to 25%, and the temperature at 18°C;

[0028] 3) One-time reverse flotation demagfification: first add acidic industrial wastewater from the phosphorus chemical industry with a pH value of 1-2 to the pulp, adjust the pH value of the pulp to 4.5 during reverse flotation demagfification, and then add 0.2 kg / t raw ore anion capture Collector WF-04, carry out a stage of reverse flotation to extract ...

Embodiment 2

[0032] For a silicon-calcium phosphate rock in Wengfu, Guizhou, raw ore P 2 o 5 26.35%, MgO 1.86%, SiO 2 16.70%, R 2 o 3 4.81%, according to the following process methods:

[0033] 1) Pre-define mud: crush the lumpy colloidal phosphorus to 1mm, remove -600 mesh fine mud through wet sieving classification, and the +600 mesh coarse grain grade part enters the grinding and floating operation;

[0034] 2) Coarse grade grinding: Grind the +600 mesh coarse grade product after fine mud removal to -200 mesh, accounting for 60%, adjust the concentration of the selected pulp at 22%, and the temperature at 20°C;

[0035] 3) One-time reverse flotation magfification: first add 10% sulfuric acid and phosphoric acid mixed acid with a mass ratio of 9:1 to the pulp to adjust the pH value of the pulp to 5.0 during reverse flotation demagfification, and then add 0.3 kg / t Raw ore anion collector WF-04, carry out a stage of reverse flotation to extract phosphorus and remove magnesium iron, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com