Slurry suction type mineral flotation machine and application thereof

A flotation machine and mineral technology, applied in the direction of flotation, solid separation, etc., can solve the problems such as the full combination of difficult minerals and air bubbles, the unsmooth beneficiation process, and the unstable process indicators. The effect of increased spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

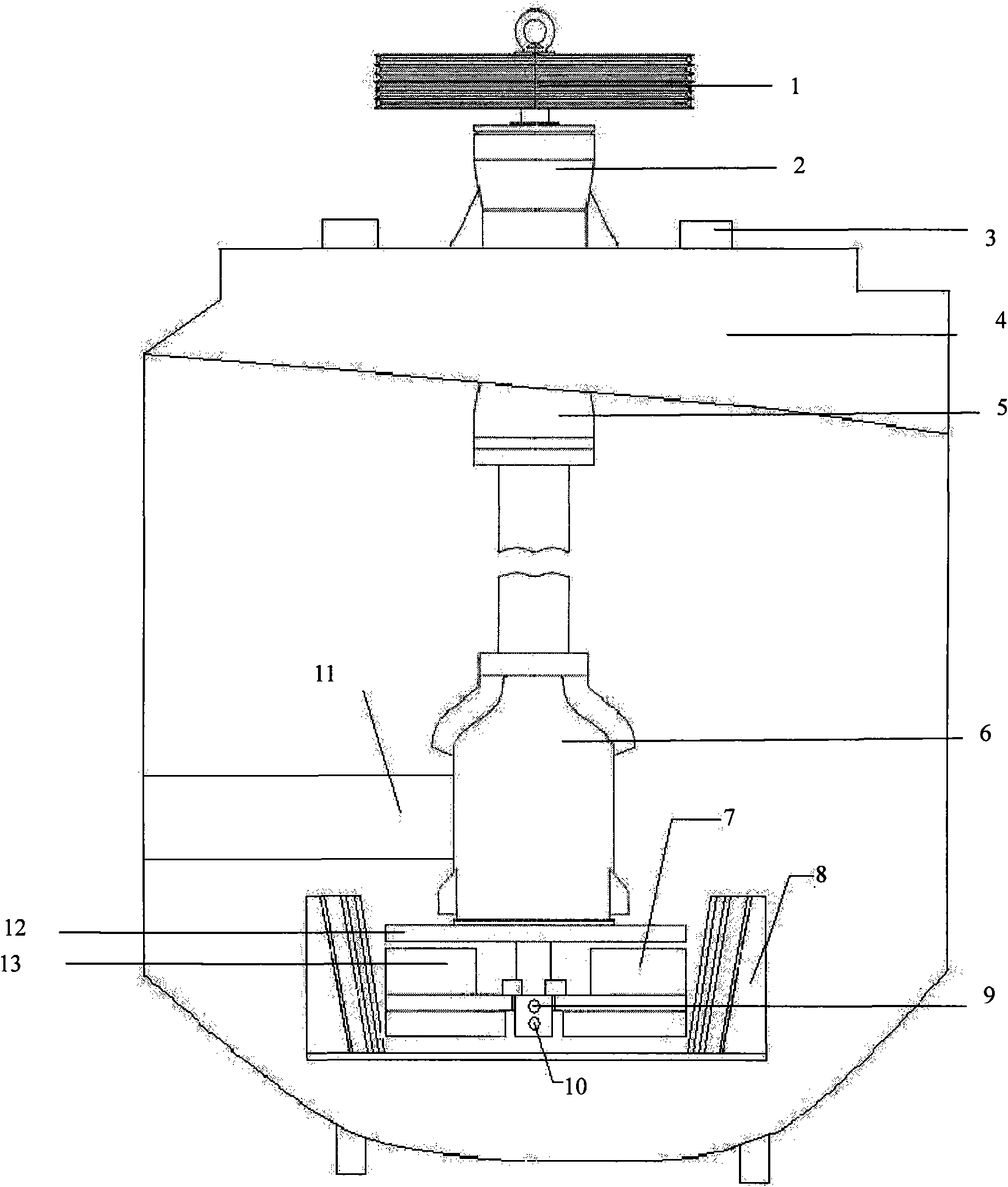

[0027] The structure diagram of the slurry suction mineral flotation machine is as follows: figure 2 As shown, among them, 1 is the large pulley, 2 is the upper bearing body, 3 is the air duct, 4 is the artesian outlet, 5 is the lower bearing body, 6 is the semi-central cylinder, 7 is the rotor impeller, 8 is the stator, 9 is the counter Valve stop float, 10 is an air distributor, 11 is a slurry suction pipeline, 12 is an impeller cover plate, and 13 is a main shaft.

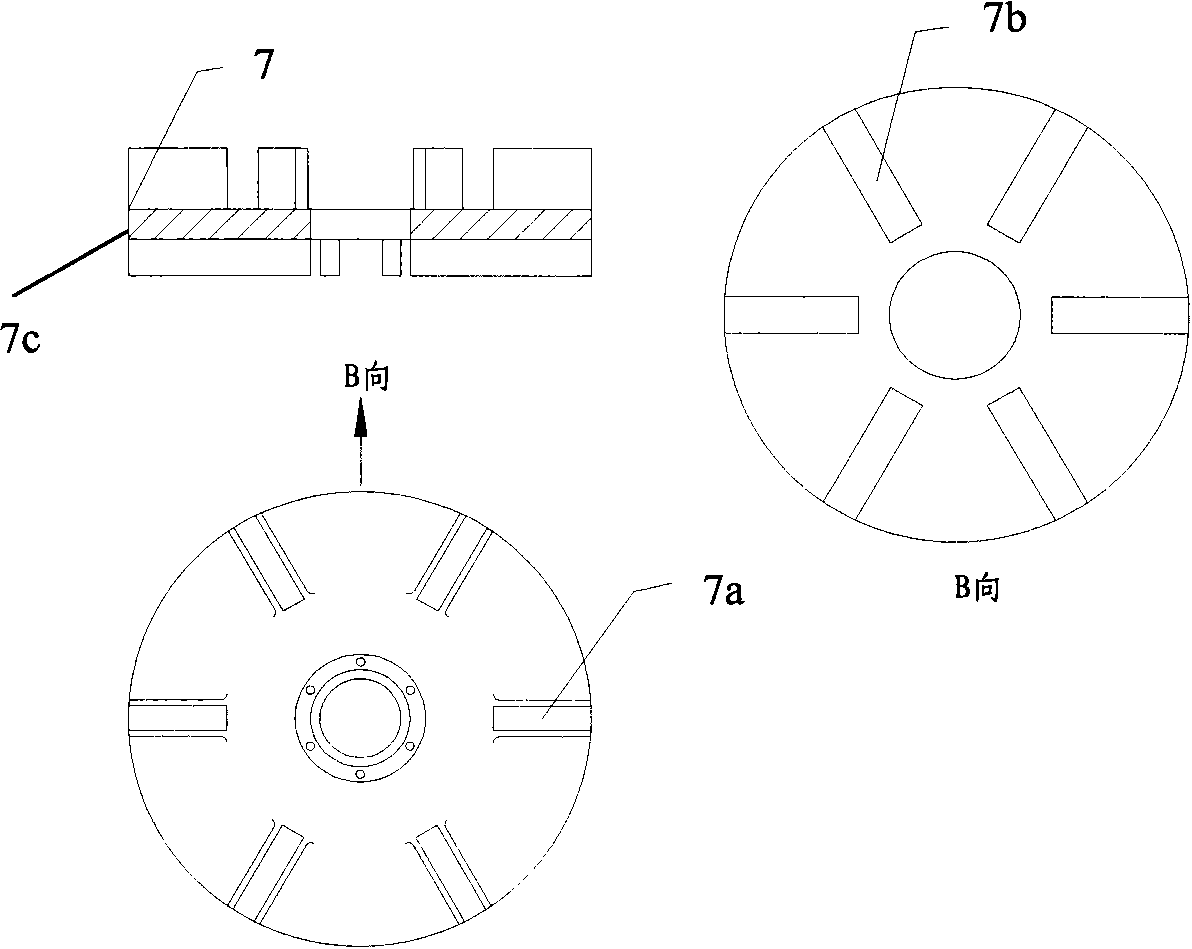

[0028] The flotation machine includes a cavity ( figure 2 Not marked in) and the main shaft 13 located at the center of the cavity and the bearing body that supports the main shaft and is installed concentrically with the main shaft, the bearing body is composed of an upper bearing body 2 and a lower bearing body 5; wherein, the flotation The machine also includes coaxial installation with the main shaft and consists of an impeller cover plate 12, an upper suction blade 7a located under the impeller cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com