Methyl tetrahydrophthalic anhydride continuous production system and method

A technology of methyltetrahydrophthalic anhydride and a production system, applied in the chemical industry, can solve the problems of not really realizing continuous production of methyltetrahydrophthalic anhydride, low efficiency, etc., and achieve improved product quality stability, low energy consumption, and residence time. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

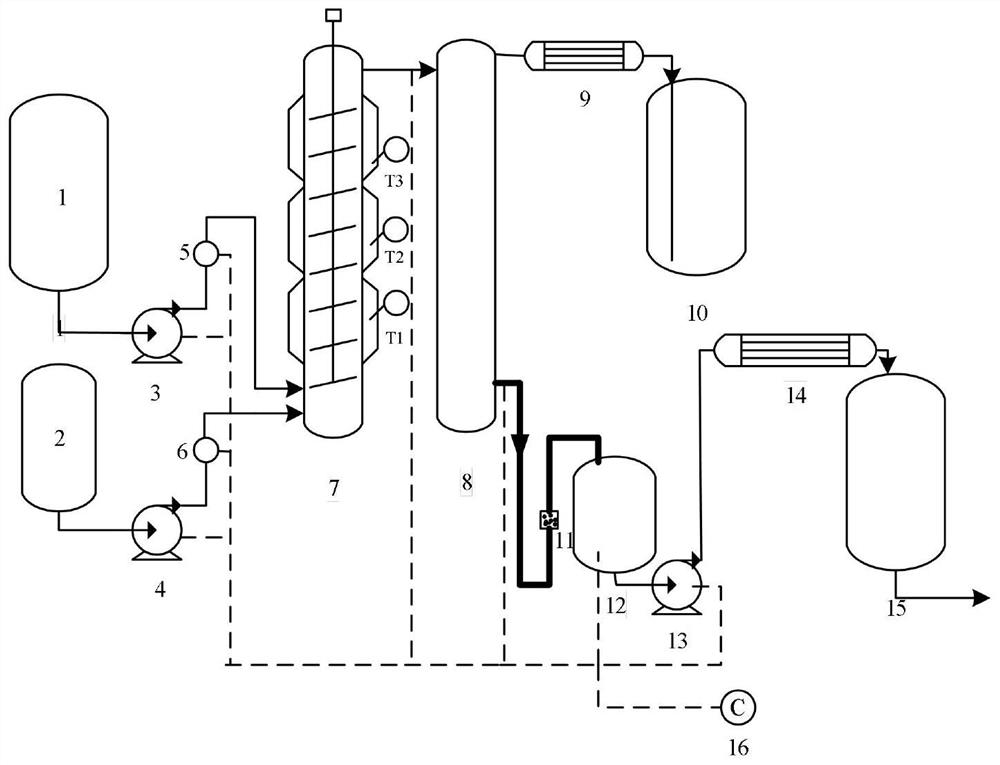

[0019] Such as figure 1 As shown, the continuous production system of methyl tetrahydrophthalic anhydride includes a tower reactor 7, a carbon five storage tank 1, a maleic anhydride storage tank 2, a thin film evaporator 8, a carbon five receiving tank 10, an adiabatic evaporator 12 and a finished product Groove 15, carbon five storage tank 1 is connected tower reactor 7 by first magnetic force pump 3, and maleic anhydride storage tank 2 is connected tower reactor 7 by second magnetic force pump 4, and tower reactor 7 is connected thin film evaporator 8, The thin film evaporator 8 includes a steam outlet and a liquid outlet, the steam outlet is connected to the carbon five receiving tank 10 through the first condenser 9, the liquid outlet is connected to the adiabatic evaporator 12, and a catalyst holder 11 is arranged between the liquid outlet and the adiabatic evaporator 12 , the adiabatic evaporator 12 is connected to the second condenser 14 through the third magnetic pump...

Embodiment 2

[0026]The raw material with a molar ratio of maleic anhydride to C5 of 1:1.05 is transported to the tower reactor at 5T / h through the first metering pump and the second metering pump respectively, and the synthesis temperature in the tower reactor is controlled to be 70-75 ℃, to ensure that the reactant stays in the tower reactor for 40 seconds and then enters the thin-film evaporator whose temperature is controlled at 116-118℃. Under the condition of vacuum greater than -0.98MPa, the unreacted C5 is extracted and condensed to recover. The liquid at the bottom enters the heat-conducting oil heating jacket pipe whose temperature is set at 170-175°C. After heating, it enters the catalyst holder with catalyst for isomerization reaction, and then enters the adiabatic evaporator whose temperature is controlled at 136-140°C. . The vaporized products are condensed and collected by the second condenser. Finally, the product yield was 98.92%, and the degree of isomerization was 36.7%....

Embodiment 3

[0028] The raw material with a molar ratio of maleic anhydride to C5 of 1:1.10 is transported to the tower reactor at 4T / h through a metering pump, and the synthesis temperature is controlled at 70-73°C to ensure that the residence time of the reactants in the tower reactor is 30 Seconds later, it enters the thin-film evaporator whose temperature is controlled at 112-115°C, and under the condition of vacuum greater than -0.98MPa, the unreacted C5 is extracted and condensed to recover. The liquid at the bottom enters the jacketed pipe heated by heat transfer oil at a temperature of 165-170°C, undergoes isomerization reaction in a catalyst holder with a catalyst, and then enters an adiabatic evaporator with a controlled temperature of 132-135°C for gasification The product is condensed and collected by the second condenser. Finally, the product yield was 98.73%, and the degree of isomerization was 35.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com