Silicone oil and continuous preparing method thereof

A technology of silicone oil and dimethylsiloxane, applied in the field of preparation of silicon-containing compounds, can solve the problems of easy blockage, explosion, high product unit consumption and energy consumption of D3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

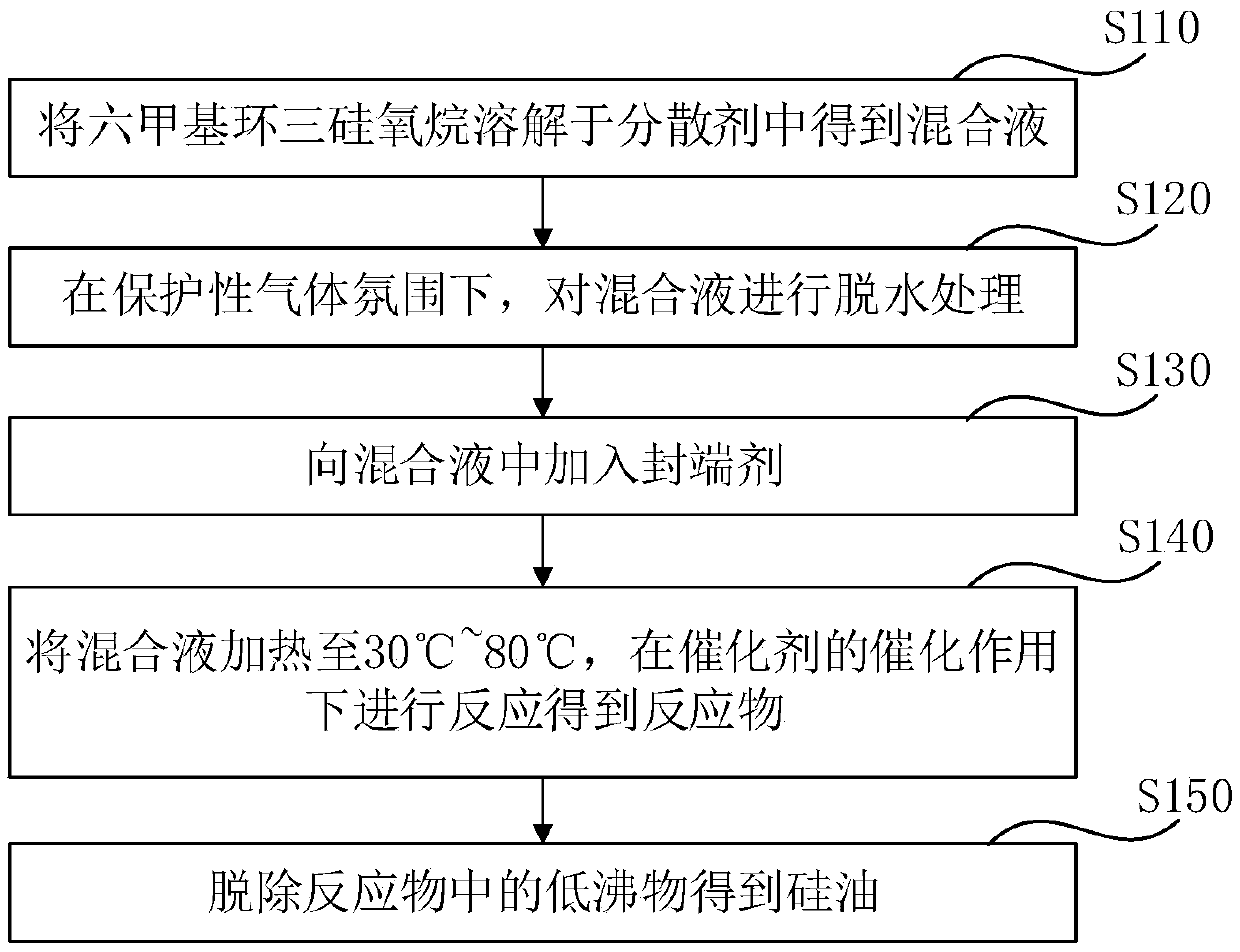

[0030] see figure 1 , the continuous preparation method of the silicone oil of one embodiment, comprises the following steps:

[0031] S110, dissolving hexamethylcyclotrisiloxane in a dispersant to obtain a mixed solution.

[0032] In one embodiment, the dispersant is at least one of octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane and dimethylsiloxane mixed rings.

[0033] In one embodiment, at least one of tetramethyltetravinylcyclotetrasiloxane, methylphenylcyclosiloxane and diphenylcyclosiloxane may also be added to the dispersant.

[0034] When tetramethyltetravinylcyclotetrasiloxane is added to the dispersant, the product obtained is vinyl silicone oil; when methylphenylcyclosiloxane and diphenylcyclosiloxane are added to the dispersant , the product obtained is phenyl silicone oil.

[0035] In one embodiment, the temperature of the dispersant is heated to 35° C. to 60° C., and then hexamethylcyclotrisiloxane is added therein, and stirred until the hexamethy...

Embodiment 1

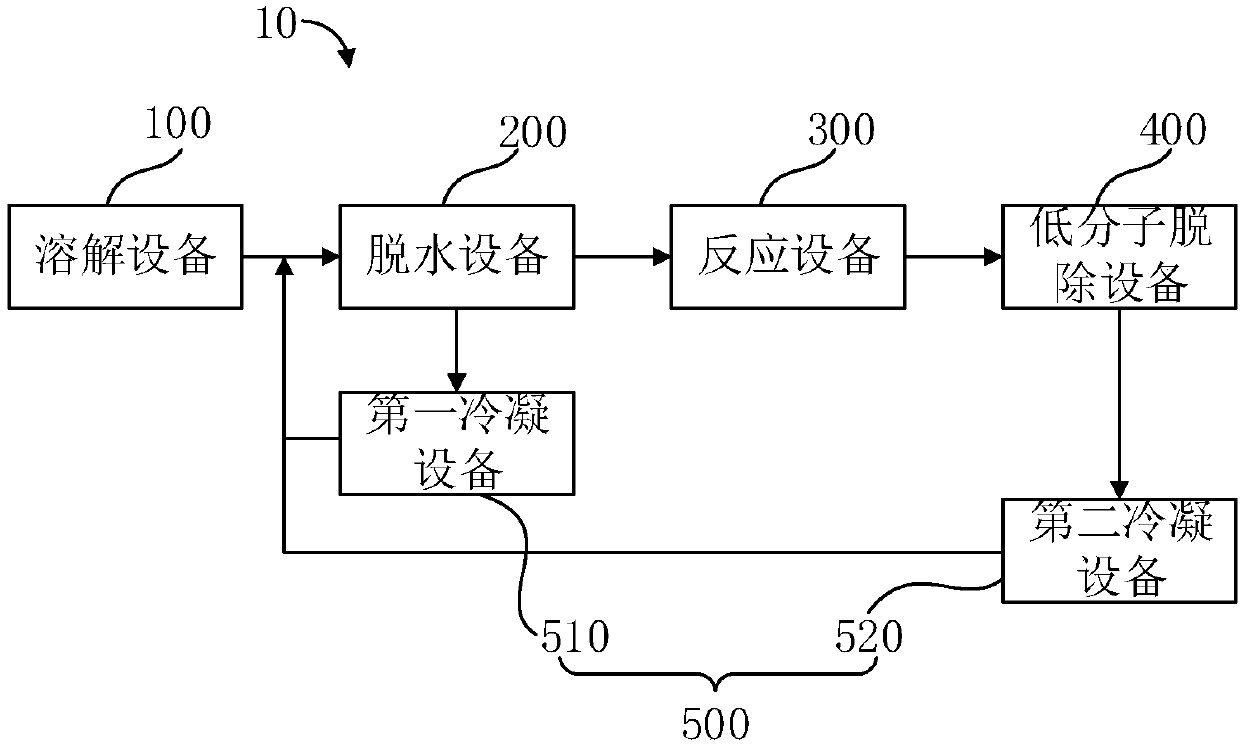

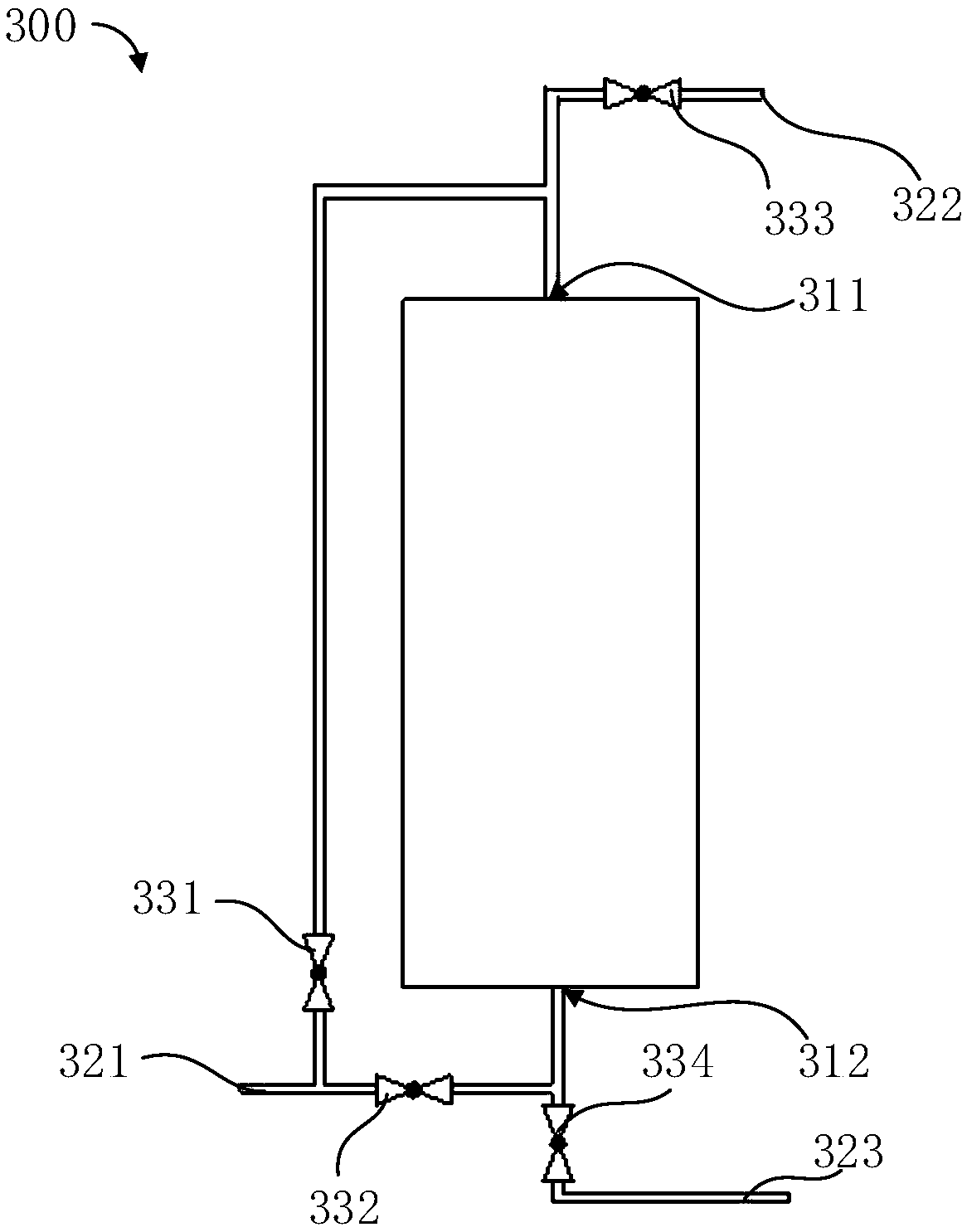

[0095] Add 900Kg of dimethylsiloxane mixed rings into the dissolving device, heat to 65°C, then add 400Kg of hexamethylcyclotrisiloxane into the dissolving device and stir until completely dissolved to obtain a mixed solution. Import the above mixed solution into the dehydration equipment, heat it to 95°C, blow nitrogen into the dehydration equipment, and keep the vacuum at -0.09MPa for dehydration treatment for 1 hour. During the dehydration treatment, use a spray tower to dehydrate The overflow is treated by spraying, and the condensate recovered after spraying is introduced into the dissolution equipment for recycling. Add 65Kg of dehydrated hexamethyldisiloxane as an end-capping agent to the dehydrated mixed solution, heat it to 50°C and introduce it into the reaction equipment, and place excess macropores on the fluidized bed of the reaction equipment Cationic exchange resin, the mixed solution undergoes a fluidized bed catalytic reaction for 40 minutes to obtain the reac...

Embodiment 2

[0097] Add 900 Kg of octamethylcyclotetrasiloxane into the dissolving device, heat to 35° C., then add 9 Kg of hexamethylcyclotrisiloxane into the dissolving device and stir until completely dissolved to obtain a mixed solution. Import the above mixed solution into the dehydration equipment, heat it to 95°C, blow nitrogen into the dehydration equipment, and keep the vacuum at -0.08MPa for dehydration treatment for 1.5h. During the dehydration treatment, use a spray tower to dehydrate The treated overflow is sprayed, and the condensate recovered after spraying is introduced into the dissolution equipment for recycling. Add 300Kg of dehydrated tetramethyldivinyldisiloxane to the dehydrated mixed solution as an end-capping agent, heat it to 80°C and introduce it into the reaction equipment, and place an excess amount on the fluidized bed of the reaction equipment macroporous cation exchange resin, and the mixed solution was subjected to a fluidized bed catalytic reaction for 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com