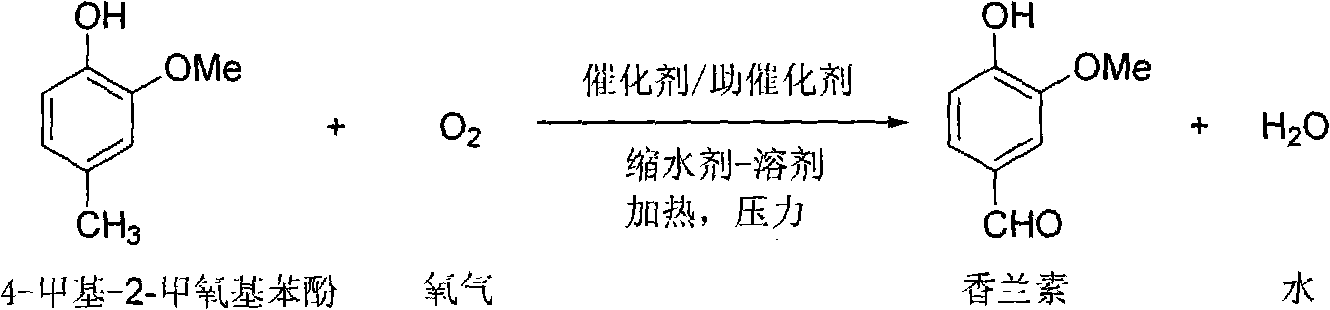

Method for synthesizing vanillin

A vanillin and material technology, applied in the field of safety technology, can solve the problems of poor control of reaction pressure, large explosion hazard, explosion hazard, etc., and achieve the effects of accelerating the oxidation reaction speed, reducing the amount of hydrochloric acid, and shortening the reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

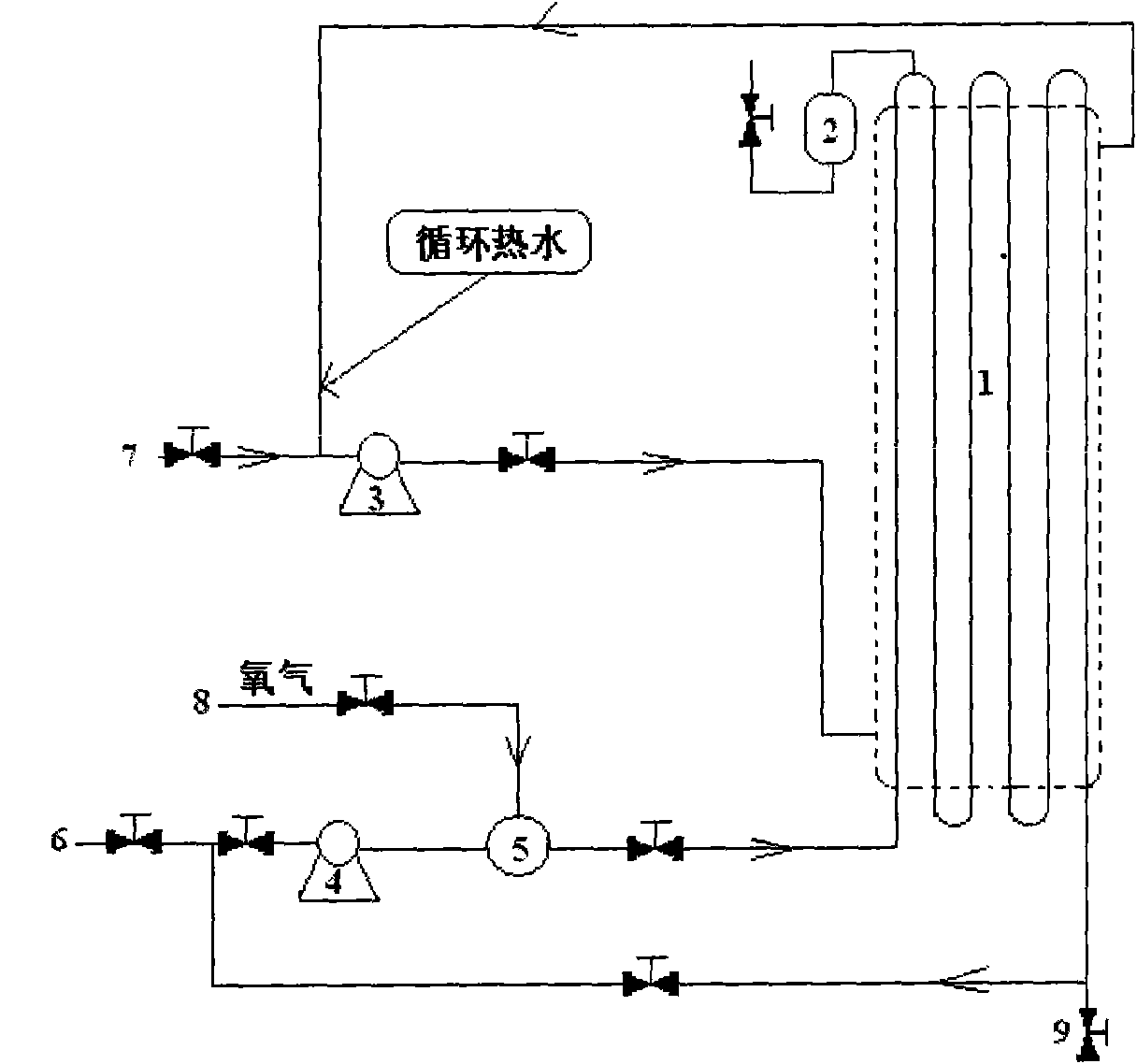

[0032] In 300 liters of pressure reactors, add 12 kilograms of sodium hydroxide, 50 kilograms of ethylene glycol monomethyl ethers, 15 kilograms of 4-methyl-2-methoxyphenols of artificial chemical synthesis, stir (rotating speed 130 revs / min) 10 Minutes later, add 135 grams of cobalt dichloride hexahydrate as a catalyst and 0.7 grams of manganese acetate tetrahydrate as a cocatalyst, seal the kettle, heat up and stir the mixture at 120° C. for 10-15 minutes. Stop heating, and when the temperature drops to about 70°C, the reaction materials are introduced into a loop-type slurry reactor.

[0033]The temperature of the reaction material is controlled at 70° C., oxygen is introduced to start the oxidation reaction, and the pressure in the reactor is controlled at 0.3-0.5 MPa. Oxygen is fed intermittently to maintain the temperature of the reaction mass at 75-80°C. When the reaction almost no longer absorbs oxygen (reaction ends in about 5 hours), take 5 milliliters of the reacti...

Embodiment 2

[0035] Using recovered ethylene glycol monomethyl ether as a solvent, repeating the operation of Example 1, the yield of vanillin product was 81%.

Embodiment 3

[0037] Use ethylene glycol monoethyl ether as solvent, repeat the operation of Example 1, and the yield of vanillin product is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com