Method for producing pentamethylene diamine by using carbon dioxide desorption process through fermentation

一种二氧化碳、戊二胺的技术,应用在基于微生物的方法、化学仪器和方法、生物化学设备和方法等方向,能够解决戊二胺羧酸盐收率低、有机溶剂需要回收、毒性高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

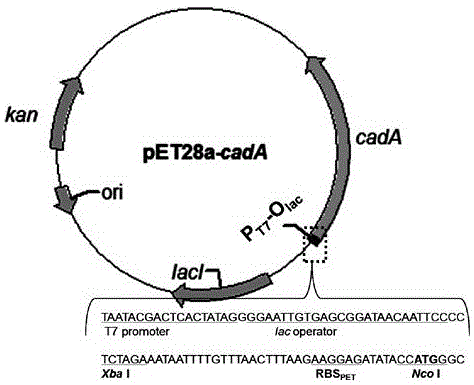

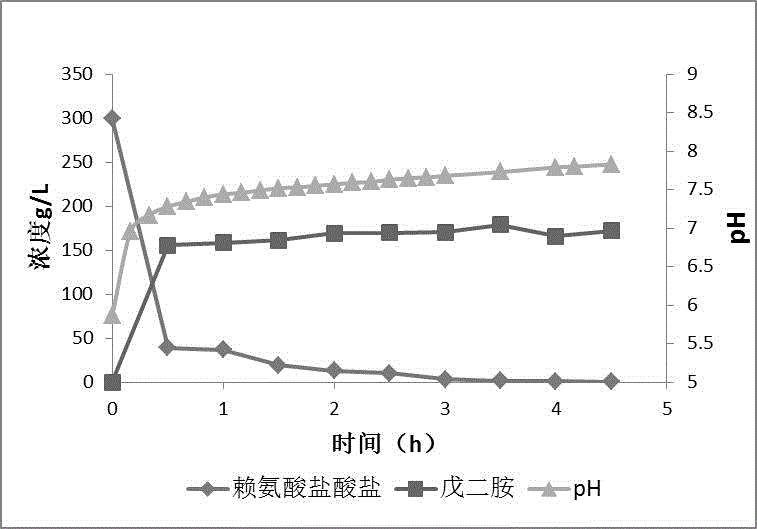

[0021] The present inventor previously established a whole-cell catalytic pentamethylenediamine production process using by-product carbon dioxide to self-control pH. Theoretically, the catalytic reaction solution contains equimolar pentamethylenediamine and carbon dioxide (carbonate ions).

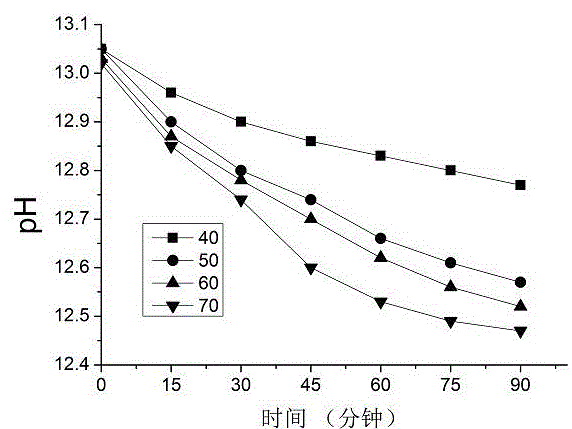

[0022] The present inventors have further researched and found that the carbon dioxide produced when lysine decarboxylation in the whole cell catalytic solution is decarboxylated to generate pentamethylenediamine can be removed by decompression and heating treatment, so that the pH of the catalytic solution is increased; Under the same alkaline conditions, the amount of alkali used after removing carbon dioxide is significantly reduced, and the subsequent distillation yield of pentamethylenediamine is obviously increased. On this basis, a method for separating and extracting pentamethylenediamine from the pentamethylenediamine salt ion catalytic liquid has been established, and the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com