Method and device for separating mixed substances in reaction solution for oxidation of phenol with hydrogen peroxide

A technology of liquid mixture and oxidation of phenol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve problems such as low yield, low production efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

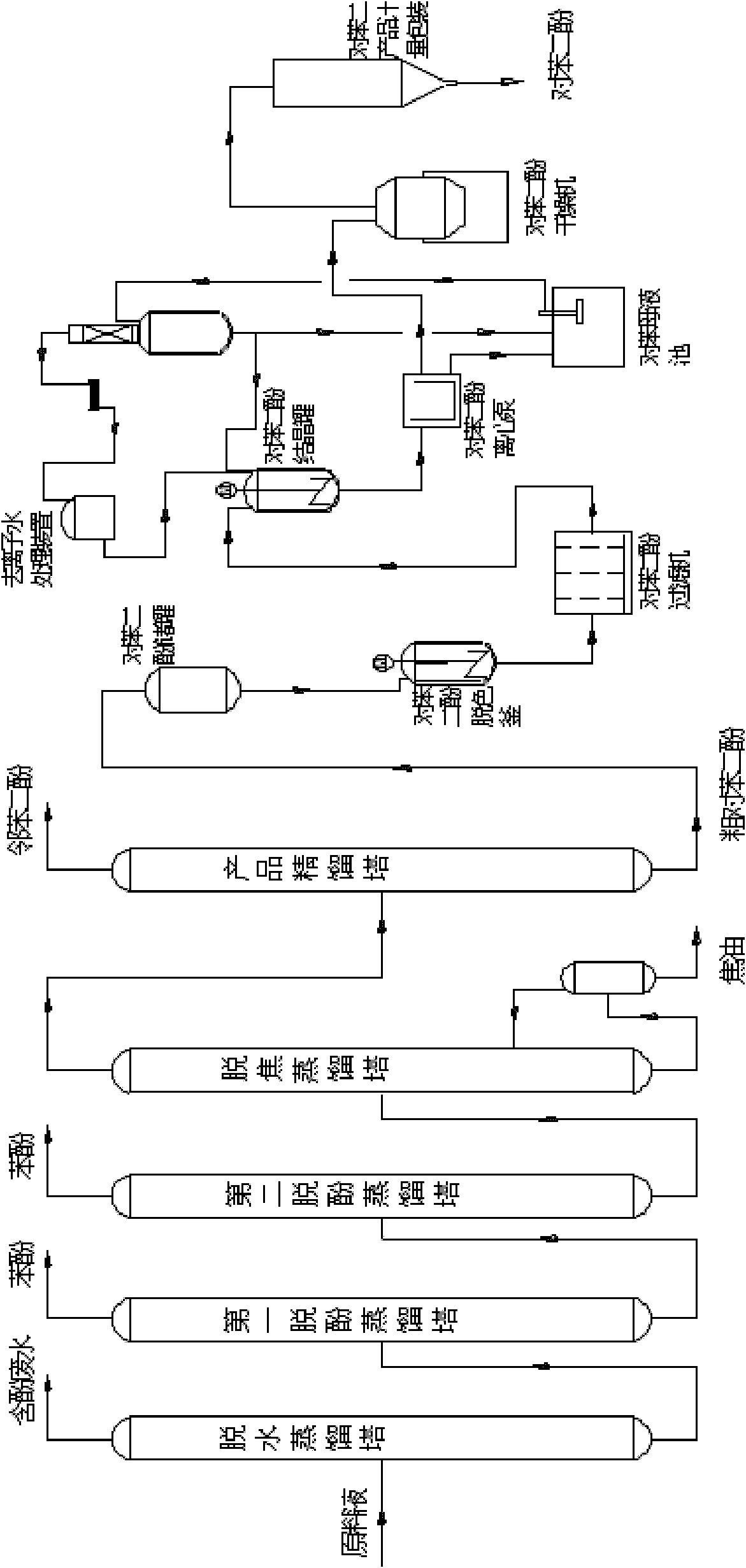

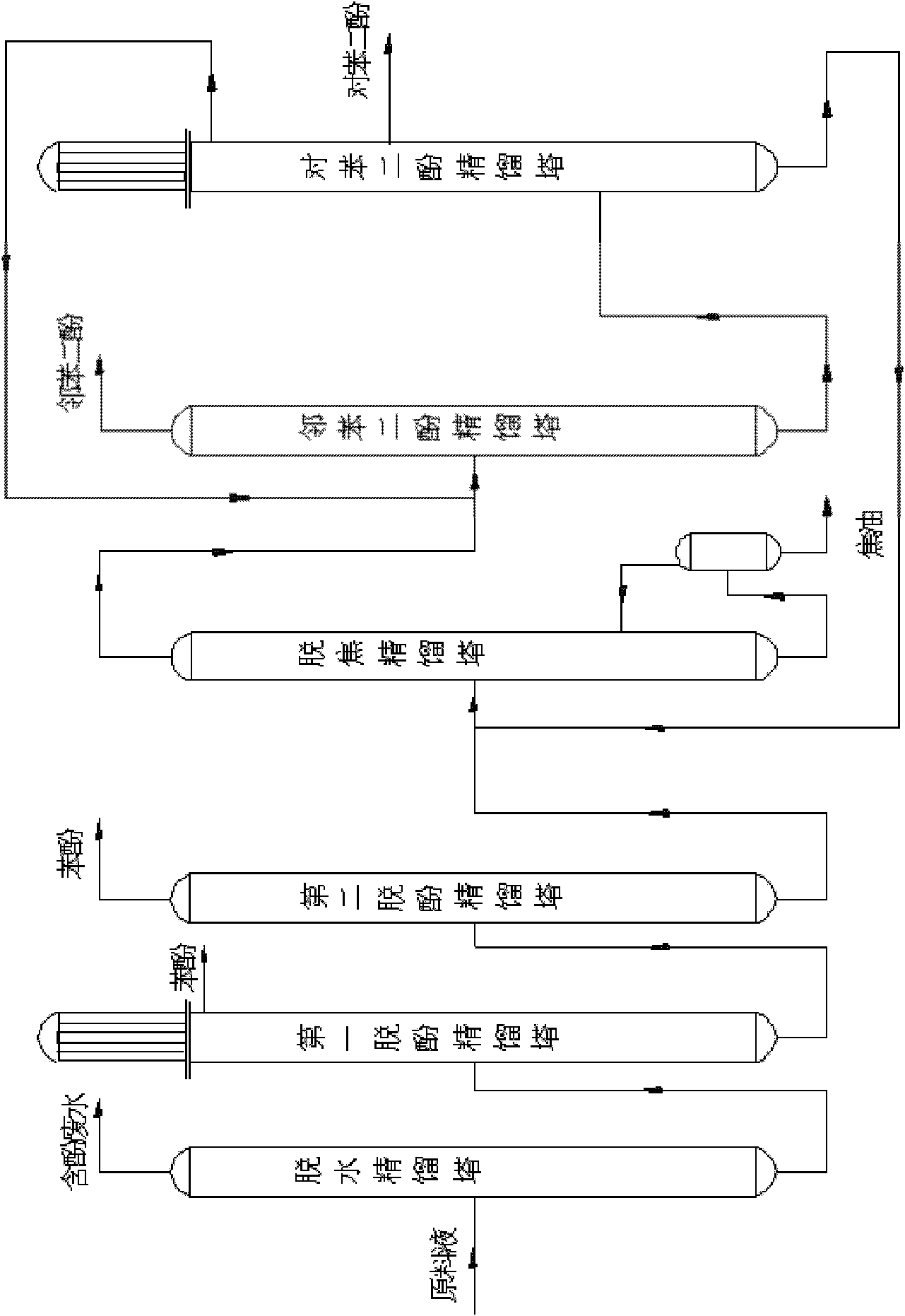

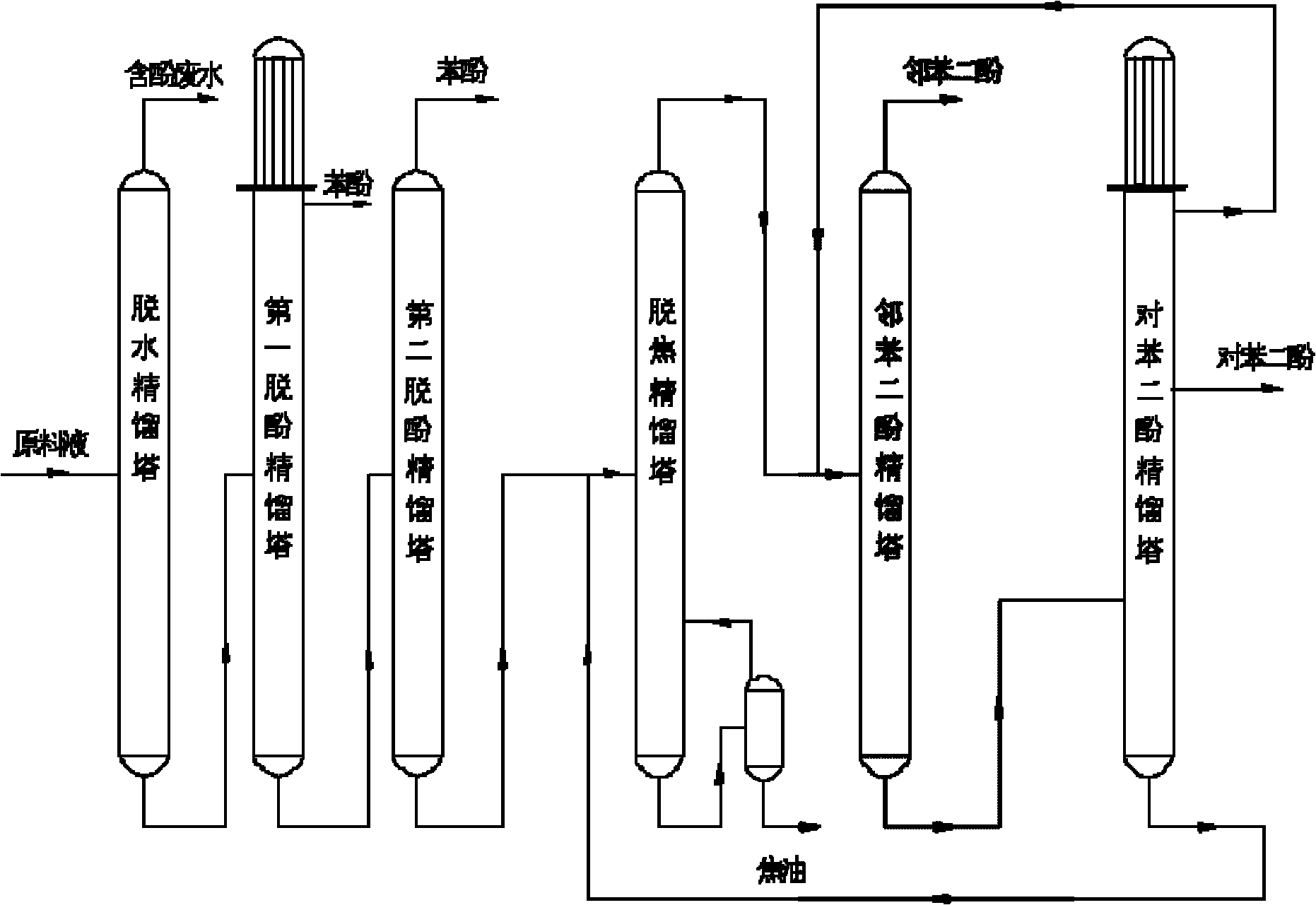

Method used

Image

Examples

Embodiment 1

[0024] The raw material liquid (the quality of the raw material liquid consists of 20% water, 68% phenol, 3% catechol, 5% hydroquinone and 4% tar) is passed into the dehydration rectification tower with a flow rate of 6000kg / h, and then Carry out rectification by the first dephenol rectification tower, the second dephenol rectification tower and decoking rectification tower successively, the operation pressure in the tower of the first described first dephenol rectification tower is normal pressure and its tower top and The pressure difference at the bottom of the tower is 2kPa; the components distilled from the top of the decoking distillation tower are sent to the pyrocatechol rectification tower with a flow rate of 500kg / h, and are separated from the pyrocatechol rectification tower by rectification. The high-purity pyrocatechol product is distilled out from the top of the distillation tower, and the operating pressure in the said pyrocatechol rectifying tower is 5kPa; top)...

Embodiment 2

[0026] The raw material liquid (the quality of said raw material liquid consists of 50% water, 30% phenol, 9% catechol, 9% hydroquinone and 2% tar) is passed into the dehydration rectification tower with a flow rate of 3000kg / h, and then Carry out rectification by the first dephenol rectification tower, the second dephenol rectification tower and decoking rectification tower successively, the operation pressure in the tower of the first described first dephenol rectification tower is normal pressure and its tower top and The pressure difference at the bottom of the tower is 3kPa; the components distilled from the top of the decoking distillation tower are sent to the pyrocatechol rectification tower with a flow rate of 550kg / h, and are separated from the pyrocatechol rectification tower after rectification separation. High-purity catechol products are distilled from the top of the distillation tower. The operating pressure in the catechol rectification tower is 8kPa; the pressu...

Embodiment 3

[0028] The raw material liquid (the quality of the raw material liquid consists of 70% water, 20% phenol, 6% catechol, 3% hydroquinone and 1% tar) is passed into the dehydration rectification tower with a flow rate of 4500kg / h, and then Carry out rectification by the first dephenol rectification tower, the second dephenol rectification tower and decoking rectification tower successively, the operation pressure in the tower of the first described first dephenol rectification tower is normal pressure and its tower top and The pressure difference at the bottom of the tower is 2.5kPa; The components after the overhead distillation of the decoking distillation tower are sent to the catechol rectification tower with a flow rate of 410kg / h, and the catechol rectification tower is separated from the catechol after rectification separation. The high-purity catechol product is distilled from the top of the rectification tower. The operating pressure in the catechol rectification tower is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com